Sliding Garage Door Roller Options for Smooth Operation and Easy Installation

Sliding Garage Door Rollers Essential Components for Smooth Operations

Sliding garage doors are an increasingly popular choice for homeowners due to their space-saving design and ease of use. However, the efficient operation of these doors largely depends on a critical yet often overlooked component the rollers. This article will delve into the significance of sliding garage door rollers, how they function, maintenance tips, and when to consider replacements.

What Are Sliding Garage Door Rollers?

Sliding garage door rollers are cylindrical devices that facilitate the smooth movement of garage doors along their tracks. These rollers are typically made from materials such as nylon, steel, or plastic, each offering different advantages in terms of durability, noise reduction, and ease of maintenance. Rollers are designed to handle the weight of the garage door while providing a frictionless experience during opening and closing.

How Do They Work?

The rollers operate in conjunction with the tracking system of the sliding garage door. When the door is pushed or pulled, the rollers glide along the tracks, allowing the door to move seamlessly. This mechanism minimizes wear and tear on the door and ensures a long service life. High-quality rollers enhance the overall automation of the door, reducing the effort required to operate it and significantly improving the user experience.

Importance of Quality Rollers

Choosing the right type of rollers is crucial for the performance and longevity of your sliding garage door. High-quality rollers can significantly reduce noise levels, minimize friction, and decrease the chances of door misalignment. On the other hand, subpar rollers might lead to frequent jams, increased wear on the door mechanism, and can even pose safety risks if a door becomes stuck.

Maintenance Tips

To ensure the longevity and smooth operation of your garage door rollers, regular maintenance is essential

. Here are some tips to help you keep them in top conditionsliding garage door rollers

1. Regular Cleaning Dust and debris can accumulate on your rollers and tracks, leading to increased friction and noise. Regularly clean these components with a damp cloth and mild detergent.

2. Lubrication Apply a silicone-based lubricant to the rollers and tracks every six months. This prevents rusting and ensures smooth movement. Avoid using grease as it attracts dirt and grime, which can cause more problems in the long run.

3. Inspection for Wear Regularly check the rollers for signs of wear or damage. If you notice any cracks, chips, or rough edges, it may be time to replace them. Keeping an eye on the condition of your rollers can prevent more significant issues down the line.

4. Track Alignment Ensure that the tracks are aligned correctly. Misalignment can cause undue stress on the rollers and lead to their premature failure. If you suspect misalignment, it may be best to consult a professional.

When to Replace Rollers

Despite proper maintenance, sliding garage door rollers may eventually wear out over time. Signs that indicate it's time to replace rollers include

- Excessive noise during operation - Difficulty opening or closing the door - Visible damage or wear on the rollers - The door coming off the tracks

When replacing rollers, it's essential to choose high-quality parts that match the specifications of your door. If you're unsure, consult with a professional for advice.

Conclusion

Sliding garage door rollers play a pivotal role in the functionality and longevity of garage doors. By understanding their importance and taking the necessary steps for maintenance and replacement, homeowners can ensure a smooth operation of their sliding garage doors for years to come. Investing in quality rollers and keeping them in good condition not only enhances convenience but also contributes to the overall safety and performance of your garage door system.

-

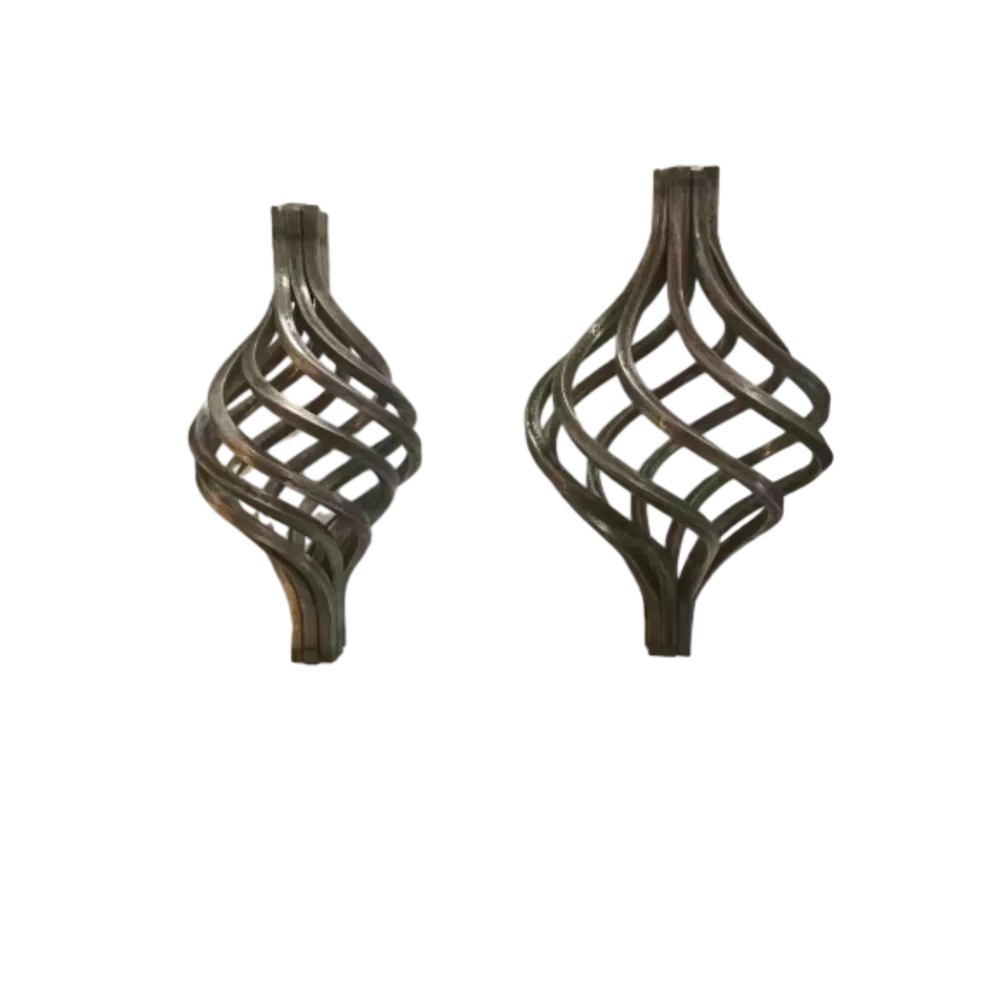

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters