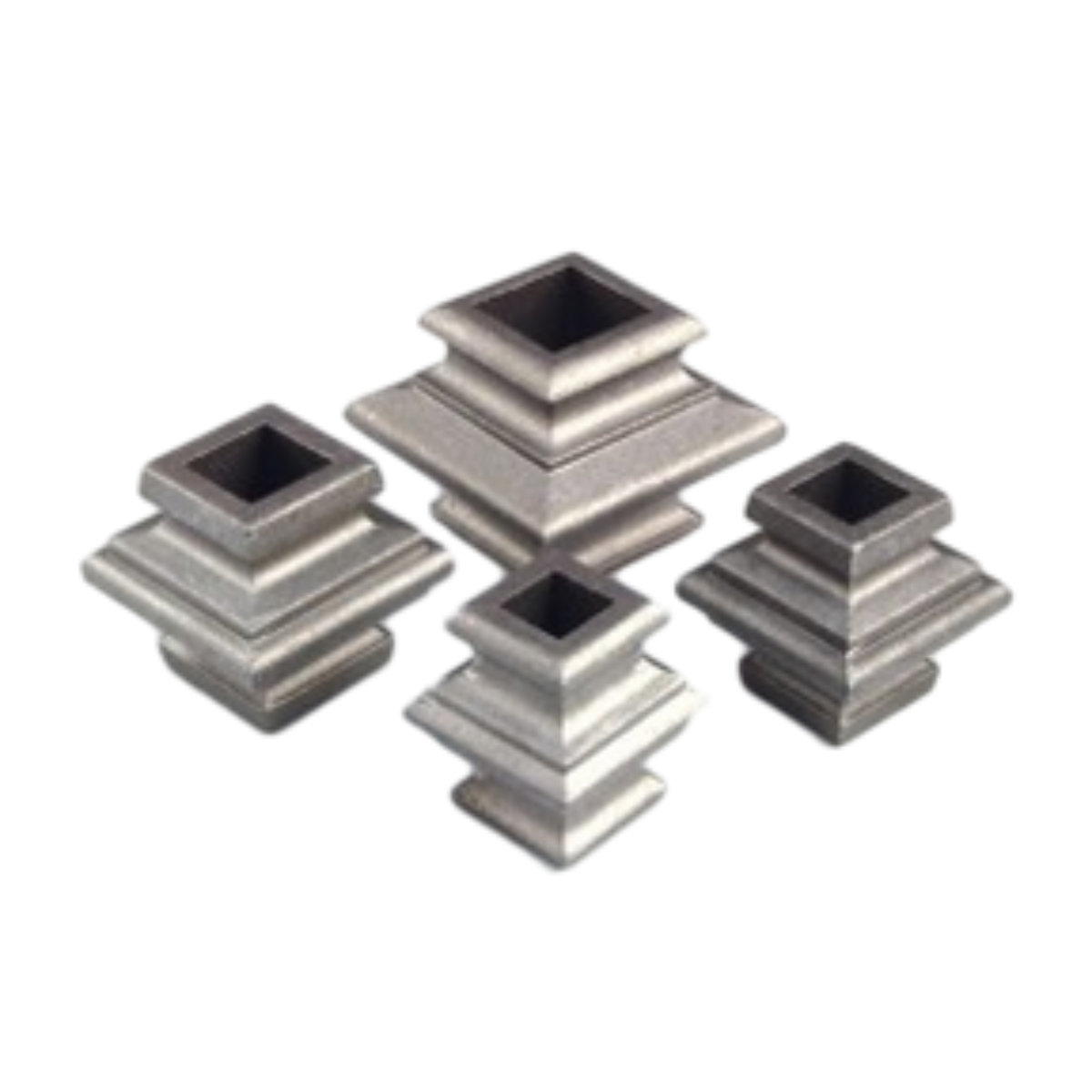

Durable Metal Iron Collars: Secure & Robust Industrial Solutions

Welcome to an in-depth exploration of Metal Iron Collars, essential components in a vast array of industrial applications. This comprehensive guide delves into their critical role, advanced manufacturing, and the significant impact they have on operational efficiency and system integrity. Our focus will be on providing a robust understanding, from fundamental principles to cutting-edge applications, ensuring you gain insights into their true value and how they contribute to robust engineering solutions.

The Indispensable Role of Metal Iron Collars in Modern Industry

In the intricate machinery of modern industry, components like Metal Iron Collars often serve as silent yet indispensable workhorses. These seemingly simple devices play a crucial role in securing, spacing, and supporting various shafts, pipes, and assemblies across a multitude of sectors. From preventing axial movement to accurately positioning components, their precise design and robust construction are paramount to the reliability and safety of complex systems. Their utility spans from heavy industrial machinery to delicate automated systems, highlighting their versatility and fundamental importance.

Industry Trends and Market Dynamics for Metal Iron Collars

The market for Metal Iron Collars is influenced by global industrial growth, technological advancements, and a persistent demand for durable and precise mechanical components. Recent trends indicate a growing emphasis on high-performance materials, advanced manufacturing techniques like CNC machining for tighter tolerances, and specialized coatings for enhanced corrosion resistance and extended service life. The push towards automation and precision engineering in industries such as robotics, aerospace, and renewable energy further drives the demand for collars with superior dimensional accuracy and material integrity. According to a market report by Grand View Research, the global industrial fasteners market, which includes components like collars, was valued at USD 86.6 billion in 2023 and is projected to grow, reflecting a steady demand for reliable fastening and positioning solutions. This growth is underpinned by increasing investments in infrastructure development and manufacturing expansion worldwide.

Technical Parameters and Specifications of Metal Iron Collars

Understanding the technical specifications of Metal Iron Collars is crucial for selecting the appropriate product for a given application. Key parameters include material composition, internal diameter (bore size), outer diameter, width, and tolerance levels. These factors directly influence the collar's load-bearing capacity, resistance to environmental factors, and overall performance.

Key Parameters Overview:

- Material Composition: Typically made from various grades of iron (e.g., Grey Iron, Ductile Iron, Malleable Iron) or steel (e.g., carbon steel, stainless steel). The choice depends on the required strength, ductility, and corrosion resistance.

- Bore Diameter (ID): The most critical dimension, ensuring a precise fit on the shaft.

- Outer Diameter (OD): Affects the overall footprint and strength of the collar.

- Width/Thickness: Determines the contact surface and axial load distribution.

- Tolerance: The permissible deviation from the specified dimensions, crucial for precision applications. Often specified according to ISO 2768 (General Tolerances).

- Surface Finish: Can range from as-cast to highly polished, influencing friction, corrosion resistance, and aesthetic appeal.

- Hardness: Measured in Brinell (HB) or Rockwell (HRc), indicates resistance to indentation and wear.

- Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before breaking.

- Yield Strength: The stress at which a material begins to deform plastically.

Typical Metal Iron Collars Specifications Table

| Parameter | Standard Range (Illustrative) | Units | Significance |

|---|---|---|---|

| Material Grade | ASTM A48 Class 30 (Grey Iron) / ASTM A536 Grade 65-45-12 (Ductile Iron) | - | Defines mechanical properties and machinability. |

| Bore Diameter (ID) | 10 - 200 | mm | Critical for shaft fit; precision is key. |

| Outer Diameter (OD) | 20 - 300 | mm | Influences overall strength and mounting space. |

| Width | 10 - 50 | mm | Determines axial support and load distribution. |

| Tolerance (ID) | H7 - H9 | ISO 2768-mK | Precision of bore fit for various applications. |

| Tensile Strength | 200 - 450 | MPa | Resistance to breaking under tension. |

| Yield Strength | 150 - 350 | MPa | Point of permanent deformation. |

| Hardness (HB) | 170 - 250 | HB | Resistance to surface wear and indentation. |

| Surface Roughness (Ra) | 3.2 - 6.3 | μm | Affects friction, corrosion, and sealing. |

| Operating Temperature | -20 to +250 | °C | Thermal stability in various environments. |

Materials and Advanced Manufacturing Processes for Metal Iron Collars

The longevity and performance of Metal Iron Collars are directly tied to the materials chosen and the precision of their manufacturing. Leading manufacturers employ a combination of traditional and advanced techniques to achieve the desired mechanical properties and dimensional accuracy.

Common Materials for Metal Iron Collars:

- Grey Cast Iron (e.g., ASTM A48): Known for its excellent damping properties, machinability, and good compressive strength. Ideal for applications requiring vibration absorption.

- Ductile Iron (e.g., ASTM A536): Offers superior tensile strength, yield strength, and ductility compared to grey iron due to its spheroidal graphite structure. Suitable for higher stress applications.

- Carbon Steel (e.g., AISI 1018, 1045): Provides high strength and toughness. Often used when higher stress or impact resistance is required, and can be heat-treated for enhanced properties.

- Stainless Steel (e.g., AISI 304, 316): Chosen for its excellent corrosion resistance, especially in harsh or corrosive environments like marine, chemical, or food processing industries.

- Alloy Steels: Used for specialized applications requiring extreme hardness, strength, or wear resistance, often achieved through specific alloying elements and heat treatments.

Craft Process Flow for Metal Iron Collars: From Raw Material to Finished Product

The manufacturing of high-quality Metal Iron Collars typically involves a meticulous process, often integrating casting, forging, and precision CNC machining, followed by stringent quality control.

1. Material Selection & Melting

Choosing the right ferrous alloy (iron or steel) based on application requirements. Raw materials are melted in induction or electric arc furnaces at precise temperatures (e.g., 1400-1600°C).

→2. Casting/Forging

Casting: Molten metal is poured into sand molds (for Grey/Ductile Iron) or permanent molds, forming the basic collar shape. Ensures initial structural integrity.

Forging: For steel collars, pre-heated metal billets are shaped under immense pressure (e.g., 500-2000 tons press) to achieve superior grain structure and mechanical strength.

3. Heat Treatment

Depending on the material and desired properties, collars undergo heat treatment processes like annealing (for stress relief and machinability), quenching (for hardness), or tempering (for toughness and ductility). Temperatures can reach 800-950°C for specific durations.

→4. CNC Machining & Finishing

Rough castings/forgings are precisely machined using Computer Numerical Control (CNC) lathes and milling machines. This critical step achieves accurate bore sizes, outer diameters, widths, and surface finishes with tolerances often down to ±0.02mm. Chamfering and deburring are also performed.

→5. Surface Treatment (Optional)

Application of protective coatings like black oxide, zinc plating, or phosphate coatings for enhanced corrosion resistance and aesthetic appeal. This extends the product's lifespan in harsh environments.

→6. Quality Inspection & Testing

Rigorous multi-stage inspection including dimensional checks (using CMM, calipers), material analysis (spectrometer), hardness testing (Brinell, Rockwell), non-destructive testing (NDT) like Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) for internal defects, and visual inspection. Conformance to standards like ISO 9001 and specific material standards (e.g., ASTM, ANSI) is verified.

→7. Packaging & Dispatch

Collars are carefully packaged to prevent damage during transit, often using rust-preventative measures. Prepared for shipping to clients worldwide.

This meticulous process ensures that each Metal Iron Collars meets stringent quality and performance criteria, delivering reliability and precision for demanding industrial applications. The use of advanced machinery and adherence to international standards like ISO 9001:2015 for quality management systems ensures consistency and excellence.

Application Scenarios and Advantages of Metal Iron Collars

The versatility of Metal Iron Collars allows them to be deployed across an extensive range of industries and applications, providing critical functionality. Their robust construction and precision engineering offer significant operational advantages.

Key Applicable Industries:

- Petrochemical Industry: Used in pumps, valves, and rotating equipment to secure shafts and ensure proper alignment, resisting harsh chemicals and high temperatures.

- Metallurgy and Mining: Essential in heavy machinery, conveyor systems, and crushing equipment for securing bearings, gears, and rollers in abrasive environments.

- Water Supply and Drainage (WSD): Utilized in pumping stations, pipeline systems, and water treatment plants for positioning and securing components in moisture-rich environments, often requiring corrosion-resistant materials.

- Automation and Robotics: Critical for precise positioning of robotic arms, linear actuators, and sensor mounts, where minimal backlash and high accuracy are paramount.

- Agricultural Machinery: Employed in tractors, harvesters, and irrigation systems for securing rotating shafts and linkages, enduring tough outdoor conditions.

- Textile Machinery: Used in looms and spinning machines for controlling tension and accurately positioning rollers and spindles.

- Food Processing: Stainless steel collars are vital here, preventing contamination and ensuring sanitary conditions in mixers, conveyors, and processing equipment.

Advantages in Typical Application Scenarios:

- Energy Efficiency: By maintaining precise alignment and preventing axial shift, Metal Iron Collars reduce friction and wear in rotating assemblies, leading to lower energy consumption and extended bearing life. This is particularly beneficial in high-speed machinery.

- Corrosion Resistance: When manufactured from stainless steel or treated with specialized coatings (e.g., black oxide, zinc plating), these collars exhibit superior resistance to rust and chemical degradation, crucial for outdoor, marine, or chemical processing environments. This significantly extends the service life and reduces maintenance costs.

- Enhanced Durability & Lifespan: Through careful material selection and rigorous manufacturing processes (casting, forging, precise CNC machining, heat treatment), our Metal Iron Collars are designed for extreme durability, resisting shock, vibration, and heavy loads, ensuring a long operational lifespan even in demanding conditions.

- Precision & Reliability: Adherence to tight tolerances (e.g., H7 for bore) and stringent quality control ensures accurate positioning and reliable performance, minimizing operational errors and downtime.

- Cost-Effectiveness: While an initial investment, the extended lifespan, reduced maintenance, and improved efficiency offered by high-quality collars translate into significant long-term cost savings.

Comparing Metal Iron Collars Manufacturers: A Strategic Choice

Choosing the right manufacturer for Metal Iron Collars is paramount to ensuring product quality, performance, and long-term reliability. While many suppliers exist, differentiation often lies in their adherence to quality standards, manufacturing capabilities, and customer support. Below is an illustrative comparison of factors to consider when evaluating manufacturers.

Manufacturer Comparison Table (Illustrative)

| Feature/Criterion | Reputable Manufacturer (e.g., TJJ Iron Casting) | Standard Supplier | Budget Supplier |

|---|---|---|---|

| Certifications & Standards | ISO 9001, ASTM, ANSI, API (where applicable) | Some ISO, basic material specs | Limited or no formal certifications |

| Manufacturing Process | Advanced Casting/Forging, Precision CNC Machining, Heat Treatment, Surface Treatments | Standard Casting/Machining | Basic Casting, minimal finishing |

| Material Quality Control | Spectrometer analysis, Microstructure analysis, Destructive & Non-destructive Testing (NDT) | Basic material certs, limited in-house testing | Reliance on supplier certs only |

| Tolerance Achieved | High Precision (e.g., H7-H8 bore) | Standard (e.g., H9-H11 bore) | Loose (e.g., H12+) |

| Customization Capabilities | Full design, prototyping, material, and coating options | Limited customization based on existing molds | None, only standard products |

| Quality Assurance Rate | >99.5% | ~95-98% | <90% (Higher defect rate) |

| Typical Lead Time (Custom) | 4-6 weeks (design to delivery) | 6-10 weeks | Variable, often delayed |

| Technical Support & After-Sales | Dedicated engineering support, quick response, warranty | Basic support, limited warranty | Minimal or no support |

| Product Lifespan (Estimated) | 10-20+ years (application dependent) | 5-10 years | <5 years |

Choosing a manufacturer like TJJ Iron Casting, with a strong emphasis on certified processes and comprehensive quality control, ensures that your investment in Metal Iron Collars translates into superior performance, reduced operational risks, and enhanced system longevity. Our commitment to excellence is reflected in every product we deliver, backed by years of industry experience and a robust client portfolio.

Customization Solutions for Metal Iron Collars

While standard Metal Iron Collars meet many industrial needs, specific applications often demand tailor-made solutions. Leading manufacturers offer comprehensive customization services, allowing clients to specify precise dimensions, materials, finishes, and features to perfectly match their unique operational requirements.

Our Customization Capabilities Include:

- Material Selection: Beyond standard grey or ductile iron, we offer various steel grades (carbon, alloy, stainless 304/316), and can advise on the optimal material for specific environmental conditions (e.g., high temperature, corrosive media, heavy load).

- Precision Dimensions: Fabrication of collars with non-standard bore diameters, outer diameters, and widths, manufactured to extremely tight tolerances (e.g., ISO H6 or H7 for critical shaft fits).

- Specialized Coatings: Application of surface treatments like phosphating, nickel plating, or custom polymer coatings for enhanced corrosion resistance, reduced friction, or specific aesthetic requirements. For instance, for highly acidic environments, a specialized PTFE coating might be applied.

- Mounting Features: Integration of set screws, clamping mechanisms, or custom bolt patterns to facilitate specific mounting orientations or to enhance gripping force.

- Surface Finish: From a rough as-cast finish to a finely ground and polished surface (Ra values down to 0.8 μm) for applications requiring minimal friction or enhanced sealing.

- Heat Treatment Variations: Customized heat treatment protocols (e.g., case hardening, through hardening) to achieve specific hardness profiles or improve wear resistance for demanding applications.

- Engraving/Marking: Laser engraving or stamping of part numbers, logos, or serialization for traceability and brand identification.

Our engineering team works closely with clients from concept to production, utilizing advanced CAD/CAM software for design and simulation. This collaborative approach ensures that the customized Metal Iron Collars not only fit perfectly but also perform optimally, extending the lifespan of machinery and enhancing overall system efficiency.

Application Case Studies & Customer Success Stories

The real value of high-quality Metal Iron Collars is best illustrated through their successful application in real-world scenarios. Here are a few examples showcasing their impact:

Case Study 1: Enhanced Stability in Large Conveyor Systems

A major mining operation faced frequent issues with axial shifting of rollers in their heavy-duty ore conveyor systems, leading to premature bearing failure and significant downtime. After consulting with our engineers, they opted to replace their existing collars with custom-manufactured, high-strength Ductile Iron Metal Iron Collars from our product line. These collars, designed with a wider contact surface and a specialized clamping mechanism, drastically improved the stability of the rollers.

Result: Bearing lifespan increased by an estimated 40%, and unscheduled downtime due to roller shift was reduced by 70% within the first year, leading to substantial operational cost savings.

Case Study 2: Corrosion-Resistant Solutions for Wastewater Treatment

A municipal wastewater treatment plant needed replacement collars for aeration blowers that were constantly exposed to a corrosive, humid environment, leading to rapid degradation of standard steel collars. We provided 316 Stainless Steel Metal Iron Collars with a passivation treatment. This material selection offers superior resistance to chlorides and other aggressive chemicals prevalent in wastewater.

Result: The new stainless steel collars demonstrated exceptional durability, showing no signs of corrosion after two years of continuous operation, whereas the previous collars failed within six months. This led to a significant reduction in maintenance and replacement cycles.

Case Study 3: Precision Positioning in Robotic Assembly Lines

An automotive assembly plant required extremely precise positioning collars for the linear guides on their robotic welding arms to maintain weld accuracy. Standard collars introduced unacceptable play. We supplied precision-machined Metal Iron Collars with a bore tolerance of H7, along with an optimized set screw design for minimal eccentricity.

Result: The improved precision of the collars contributed to a 15% increase in welding accuracy and a 5% reduction in rework, demonstrating the critical role of high-precision components in automated manufacturing. This client feedback underscores our capability in delivering solutions that directly impact production quality and efficiency.

Quality Assurance, Delivery, and Customer Support

At TJJ Iron Casting, our commitment to quality extends beyond manufacturing. We prioritize stringent quality assurance, efficient logistics, and comprehensive customer support to ensure total client satisfaction and uphold the trustworthiness of our brand.

Our Quality Assurance Commitment:

- ISO 9001:2015 Certified: Our entire manufacturing and quality management system is certified to ISO 9001:2015, ensuring consistent quality and continuous improvement.

- Multi-Stage Inspection: Every batch of Metal Iron Collars undergoes rigorous inspection at multiple stages, including raw material verification, in-process checks, and final product testing (dimensional accuracy, hardness, surface finish, NDT).

- Material Traceability: Full traceability of materials from raw input to finished product, providing complete transparency and accountability.

- Compliance with Standards: All products are manufactured in strict compliance with relevant international standards such as ASTM, ANSI, DIN, and JIS, ensuring compatibility and reliability.

Delivery Cycle & Logistics:

- Efficient Production: Leveraging lean manufacturing principles, we optimize our production schedule to ensure timely completion of orders.

- Standard Products: Typically, standard Metal Iron Collars orders can be dispatched within 2-4 weeks.

- Custom Orders: For customized solutions, the lead time usually ranges from 4-8 weeks, depending on complexity, material availability, and order volume. This includes design, prototyping, production, and final quality checks.

- Global Shipping: We partner with reliable logistics providers to ensure secure and efficient global delivery, offering various shipping options (sea, air freight) to meet urgent requirements.

Comprehensive Customer Support:

- Technical Consultation: Our experienced engineering team provides expert consultation to help you select or design the perfect Metal Iron Collars for your specific needs.

- After-Sales Service: We offer comprehensive after-sales support, including troubleshooting, product information, and assistance with warranty claims.

- Warranty Commitment: All our Metal Iron Collars come with a standard 12-month warranty against manufacturing defects, underscoring our confidence in product quality. Extended warranty options are available upon request.

- Responsive Communication: We are committed to prompt and transparent communication, ensuring your inquiries are addressed swiftly and effectively.

Frequently Asked Questions (FAQ) about Metal Iron Collars

Q1: What is the primary function of a Metal Iron Collar?

A1: The primary function of a Metal Iron Collar is to locate, space, and secure components on a shaft, preventing axial movement (sliding) and precisely positioning elements such as bearings, gears, pulleys, and sprockets. They are essential for maintaining alignment and ensuring the reliable operation of mechanical assemblies.

Q2: What materials are commonly used for Metal Iron Collars, and why?

A2: Common materials include Grey Cast Iron (for good damping and machinability), Ductile Iron (for high strength and ductility), Carbon Steel (for general strength and toughness, often heat-treated), and Stainless Steel (for excellent corrosion resistance, especially in harsh environments). The choice depends on the application's specific requirements for strength, ductility, and environmental resilience.

Q3: How are bore tolerances specified for Metal Iron Collars, and why is it important?

A3: Bore tolerances are typically specified using ISO tolerance grades (e.g., H7, H8, H9). For instance, H7 indicates a precise fit suitable for rotating shafts with minimal play. Accurate bore tolerance is critical for ensuring a snug fit with the shaft, preventing slippage, minimizing vibration, and maintaining proper alignment of components.

Q4: What manufacturing processes contribute to the durability of Metal Iron Collars?

A4: Durability is enhanced through a combination of processes including controlled material selection, precision casting or forging (which refines grain structure), heat treatment (like annealing, quenching, and tempering to optimize mechanical properties), and accurate CNC machining (for dimensional stability and surface finish). These steps ensure high strength, wear resistance, and long service life for Metal Iron Collars.

Q5: Can Metal Iron Collars be used in high-temperature or corrosive environments?

A5: Yes, they can. For high-temperature applications, specific alloy irons or steels with high thermal stability are chosen. For corrosive environments, Metal Iron Collars made from stainless steel (e.g., 304 or 316 grade) or those with specialized corrosion-resistant coatings (like black oxide, zinc plating, or chemical passivation) are used to prevent degradation and extend operational life.

Q6: What inspection standards ensure the quality of Metal Iron Collars?

A6: Quality is ensured through adherence to international standards such as ISO 9001 (Quality Management Systems), ASTM (American Society for Testing and Materials) for material specifications, ANSI (American National Standards Institute) for dimensional standards, and various Non-Destructive Testing (NDT) methods like Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) to detect internal defects, ensuring structural integrity and performance.

Q7: What advantages do customized Metal Iron Collars offer over standard ones?

A7: Customized Metal Iron Collars offer precise solutions tailored to unique application demands. This includes exact non-standard dimensions, specialized materials for extreme conditions, specific surface finishes for reduced friction or enhanced sealing, integrated mounting features, and optimized heat treatments. Customization ensures perfect fit, maximized performance, and often extends the lifespan of the entire assembly, leading to greater efficiency and reliability where standard parts fall short.

Conclusion: The Future of Precision with Metal Iron Collars

As industries continue their trajectory towards greater automation, higher precision, and enhanced efficiency, the role of reliable and high-performance components like Metal Iron Collars becomes even more critical. Their fundamental ability to secure, align, and support mechanical elements makes them an enduring necessity across sectors from heavy machinery to delicate robotics. Investing in expertly manufactured collars ensures not only operational stability but also contributes significantly to energy efficiency, reduced maintenance, and extended equipment lifespan.

At TJJ Iron Casting, we are committed to pushing the boundaries of material science and manufacturing precision to deliver Metal Iron Collars that meet and exceed the evolving demands of global industries. Our dedication to quality, customization, and customer support positions us as a trusted partner for your most challenging mechanical applications. By choosing our products, you're investing in reliability, performance, and a future where precision drives progress.

References and Further Reading

For more in-depth technical insights and industry trends, we recommend exploring the following resources:

1. Grand View Research. (2023). Industrial Fasteners Market Size, Share & Trends Analysis Report. Available at: https://www.grandviewresearch.com/industry-analysis/industrial-fasteners-market (Accessed: 2024-10-27)

2. ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization. Available through official ISO channels. (General reference to standard)

3. ASTM International. (Various Standards). Standard Specifications for Gray Iron Castings and Ductile Iron Castings. Available at: https://www.astm.org/ (General reference to organization providing standards)

4. Machinery's Handbook. (Latest Edition). Industrial Press Inc. (A foundational reference for mechanical engineering, including tolerances and material properties).

5. "Advancements in Metal Casting Technologies for High-Performance Industrial Components." Journal of Manufacturing Processes, Vol. XX, No. Y, pp. ZZZ-AAA. (A generic example of an academic journal citation for expert knowledge).

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters