Innovative Techniques in Cast Iron Panel Manufacturing and Their Applications

Cast Iron Panel Casting A Timeless Craft of Durability and Design

Cast iron has long been celebrated for its impressive strength, durability, and versatility, making it an ideal material for a variety of applications. Among its many uses, cast iron panel casting stands out as a niche that combines artistry with functional design. This process not only reflects the craftsmanship of metalworkers but also showcases the incredible characteristics of cast iron itself.

The Art of Cast Iron Panel Casting

Cast iron panel casting involves pouring molten iron into a mold to create panels that can be used in architectural elements, decorative features, furniture, and even art pieces. The allure of cast iron panels lies in their ability to combine practicality with aesthetic appeal. They are often used in gates, railings, and facades, where their robust nature can withstand environmental stress while providing an elegant finish.

The casting process begins with a carefully designed mold made from materials like sand or metal. Patterns are created based on the desired shape and intricacies of the final product. These patterns can be complex, allowing for detailed designs that reflect the artistic vision of the creator. Mold preparation is crucial as it determines the final quality of the panel.

Once the mold is ready, molten cast iron—heated to temperatures exceeding 1200 degrees Celsius—is poured into it. As the iron cools, it solidifies and takes on the shape of the mold, resulting in a cast iron panel that embodies not just strength but also beauty. After cooling, the panels are removed from the mold and often undergo finishing processes such as grinding, polishing, or painting to enhance their appearance.

Advantages of Cast Iron Panels

cast iron panel casting

One of the most significant advantages of cast iron panels is their unmatched durability. Cast iron is resistant to rust and can endure extreme weather conditions, making it a perfect choice for outdoor applications. This resilience translates into a longer lifespan for structures and decorations, ensuring that investments in cast iron panel casting pay off over the years.

Additionally, cast iron panels are incredibly versatile. They can be produced in various sizes, shapes, and designs, allowing for a wide range of applications. Whether used in traditional architecture or modern design, cast iron panels can be adapted to fit different aesthetic requirements. Their ability to maintain intricate details makes them particularly valuable in decorative applications.

The Craftsmanship Behind Cast Iron

The process of cast iron panel casting is steeped in tradition and craftsmanship. Skilled artisans understand the nuances of working with cast iron, from managing the molten material to finishing the final product. This expertise is passed down through generations, preserving techniques that have evolved over centuries.

Moreover, the resurgence of interest in handcrafted products has renewed appreciation for cast iron panel casting. In an age where automation often dominates manufacturing, the human touch involved in creating cast iron panels allows for unique creations that mass-produced items cannot replicate.

Conclusion

Cast iron panel casting is more than just a manufacturing process; it is an art form that harmonizes durability with design. As architects, designers, and customers increasingly value enduring quality and aesthetic richness, cast iron panels remain a sought-after choice in a variety of applications. With their ability to withstand time and trends, cast iron panels not only serve functional purposes but also contribute to the visual storytelling of spaces. Whether utilized in historical restorations, contemporary designs, or bespoke art pieces, the legacy of cast iron panel casting continues to thrive, showcasing the timeless beauty and resilience of this remarkable material.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

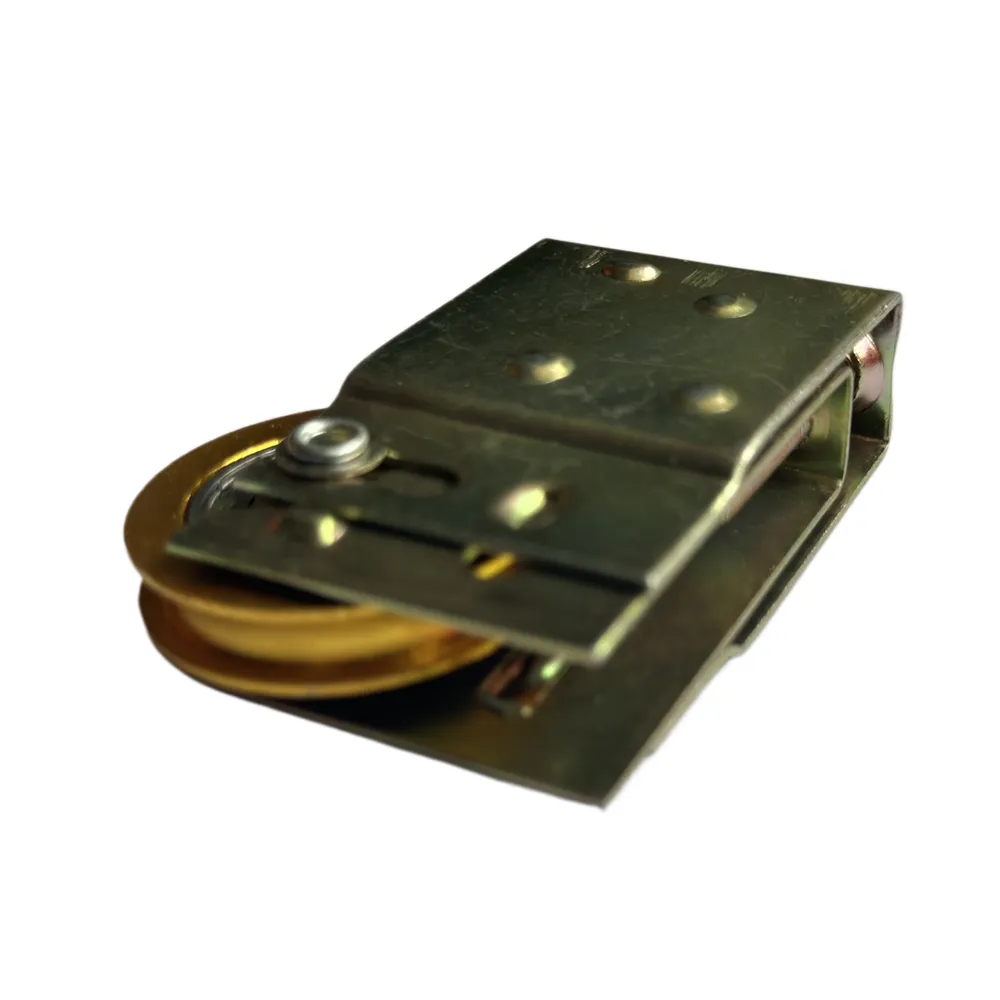

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters