Feb . 13, 2025 08:34

Back to list

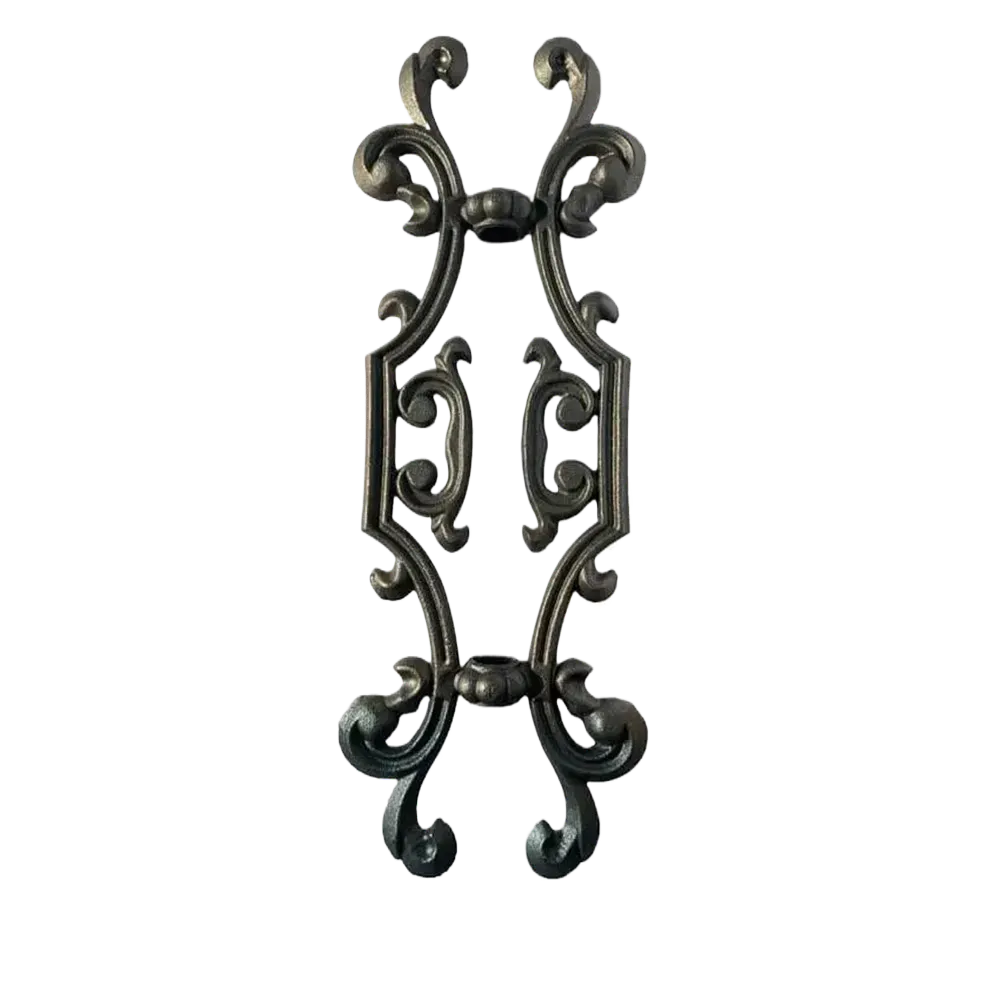

Cast Iron Rosettles

Understanding the Intricacies of Varf Forjat A Comprehensive Guide to Forged Products

Application and Benefits Products featuring Varf Forjat are often utilized in scenarios where reliability cannot be compromised. In the automotive industry, these forged components contribute to enhanced safety and performance. In aerospace, the demand for lightweight yet robust materials makes forged parts an ideal choice. The primary benefits of using Varf Forjat in your products include improved tensile strength, greater fatigue resistance, and enhanced impact toughness. These attributes ensure the longevity and dependability of components in challenging conditions. Authoritativeness in Forged Technology Businesses involved in producing Varf Forjat establish their authority through dedicated research and development. Partnerships with educational institutions and continuous investment in technology and training reinforce their position as leaders in the field. These businesses often conduct and publish research, contributing to advancements in metallurgical sciences and the evolution of forging technologies. Trustworthiness Through Quality Assurance Trust is built through consistent quality and performance. Companies producing Varf Forjat adhere to international certification standards, such as ISO 9001, to guarantee their products' reliability. By engaging in transparent business practices and maintaining open communication with clients, these companies ensure that their forged tips inspire confidence in their capability to meet customers' exacting standards. As industries continue to seek materials that offer unparalleled reliability and strength, the demand for forged products, including Varf Forjat, is poised to grow. The synergy of expertise, quality assurance, and authority in the marketplace guarantees that businesses will continue crafting products that not only meet the high expectations but also push the boundaries of innovation in metalworking. In conclusion, the world of Varf Forjat is as complex as it is fascinating. From the initial design phase to the final inspection, every step requires the careful touch of an expert hand, ensuring each forged piece stands as a testament to human ingenuity and the quest for perfection. As industries evolve, the need for high-quality forged products will undoubtedly continue to rise, further establishing Varf Forjat as an integral component in many modern applications.

Application and Benefits Products featuring Varf Forjat are often utilized in scenarios where reliability cannot be compromised. In the automotive industry, these forged components contribute to enhanced safety and performance. In aerospace, the demand for lightweight yet robust materials makes forged parts an ideal choice. The primary benefits of using Varf Forjat in your products include improved tensile strength, greater fatigue resistance, and enhanced impact toughness. These attributes ensure the longevity and dependability of components in challenging conditions. Authoritativeness in Forged Technology Businesses involved in producing Varf Forjat establish their authority through dedicated research and development. Partnerships with educational institutions and continuous investment in technology and training reinforce their position as leaders in the field. These businesses often conduct and publish research, contributing to advancements in metallurgical sciences and the evolution of forging technologies. Trustworthiness Through Quality Assurance Trust is built through consistent quality and performance. Companies producing Varf Forjat adhere to international certification standards, such as ISO 9001, to guarantee their products' reliability. By engaging in transparent business practices and maintaining open communication with clients, these companies ensure that their forged tips inspire confidence in their capability to meet customers' exacting standards. As industries continue to seek materials that offer unparalleled reliability and strength, the demand for forged products, including Varf Forjat, is poised to grow. The synergy of expertise, quality assurance, and authority in the marketplace guarantees that businesses will continue crafting products that not only meet the high expectations but also push the boundaries of innovation in metalworking. In conclusion, the world of Varf Forjat is as complex as it is fascinating. From the initial design phase to the final inspection, every step requires the careful touch of an expert hand, ensuring each forged piece stands as a testament to human ingenuity and the quest for perfection. As industries evolve, the need for high-quality forged products will undoubtedly continue to rise, further establishing Varf Forjat as an integral component in many modern applications.

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters