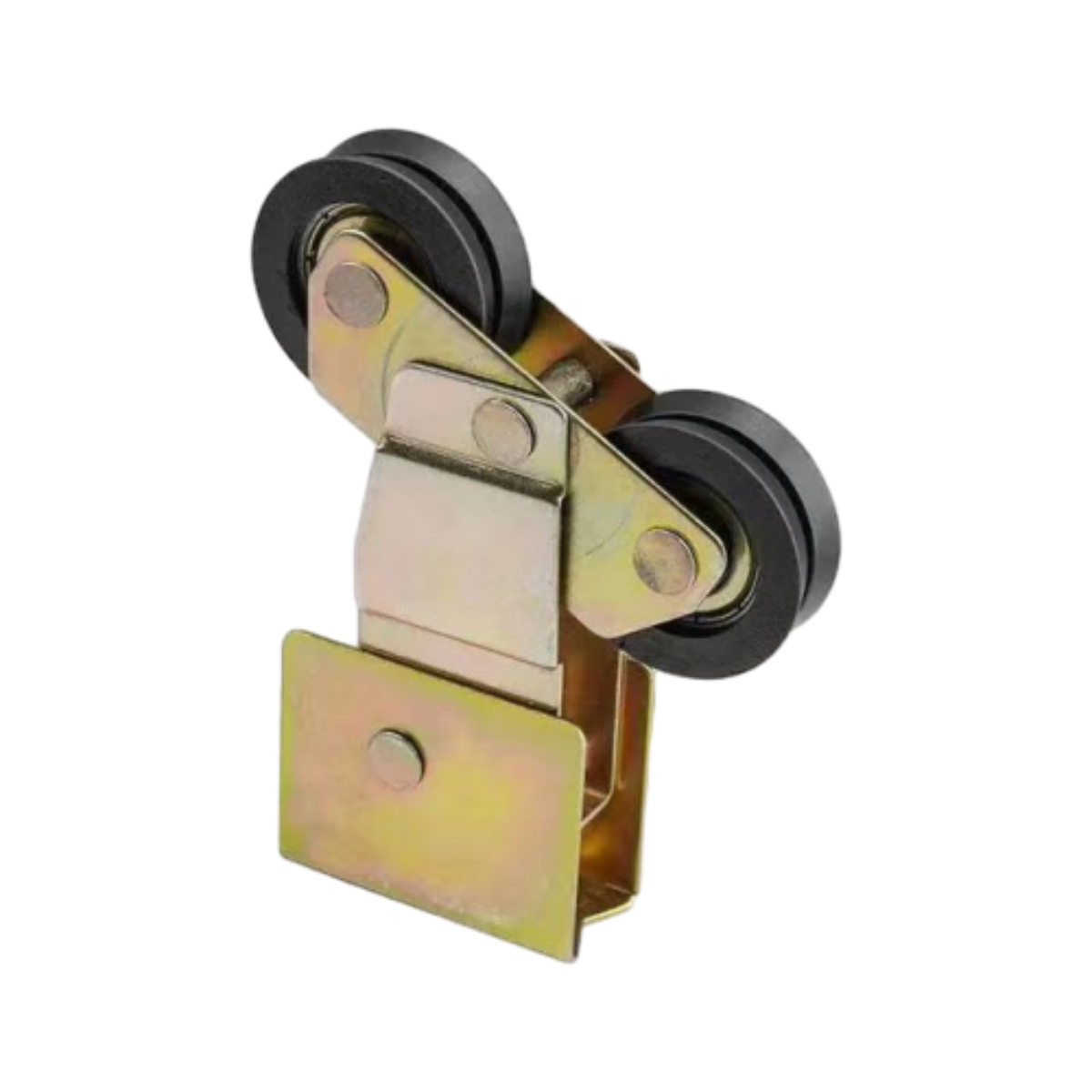

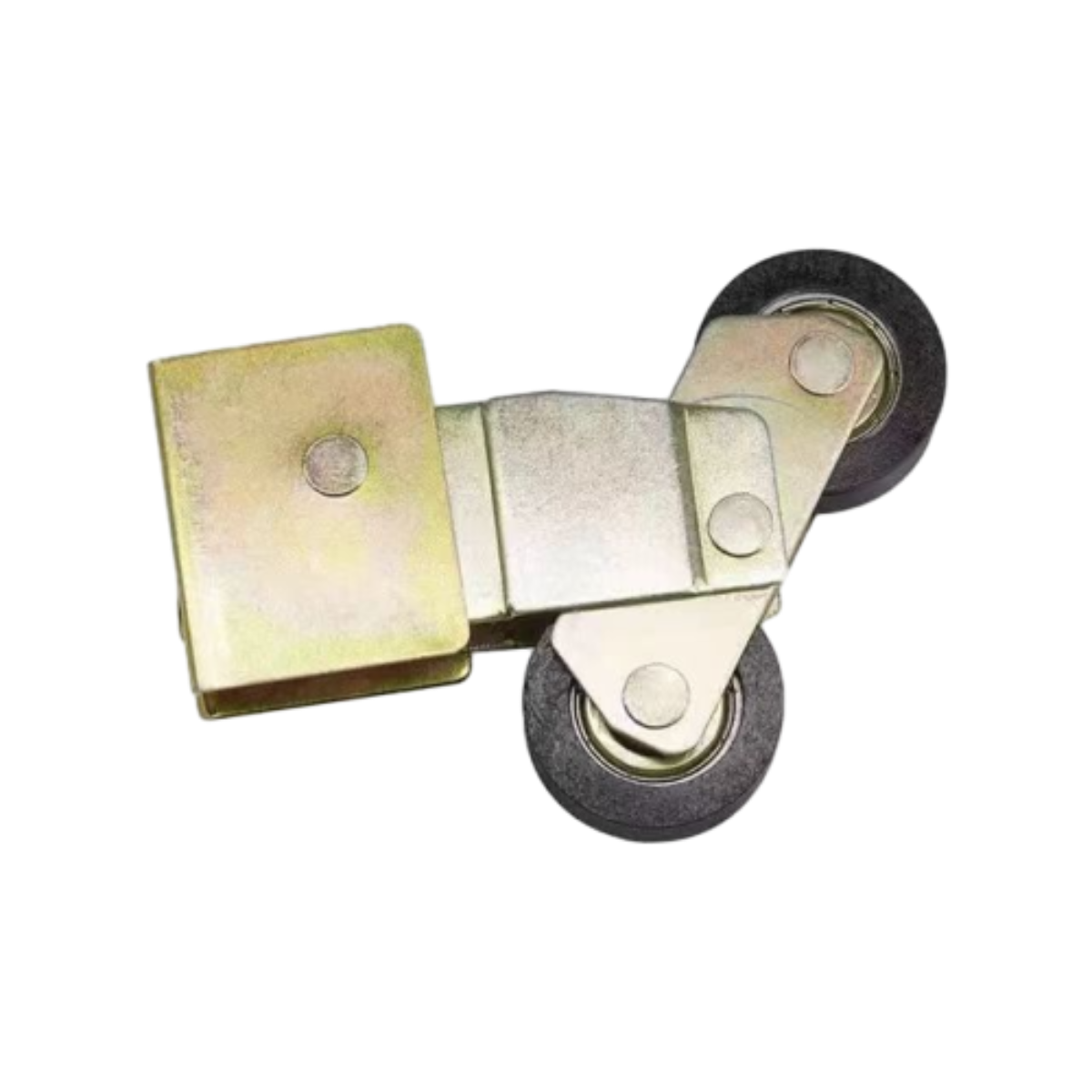

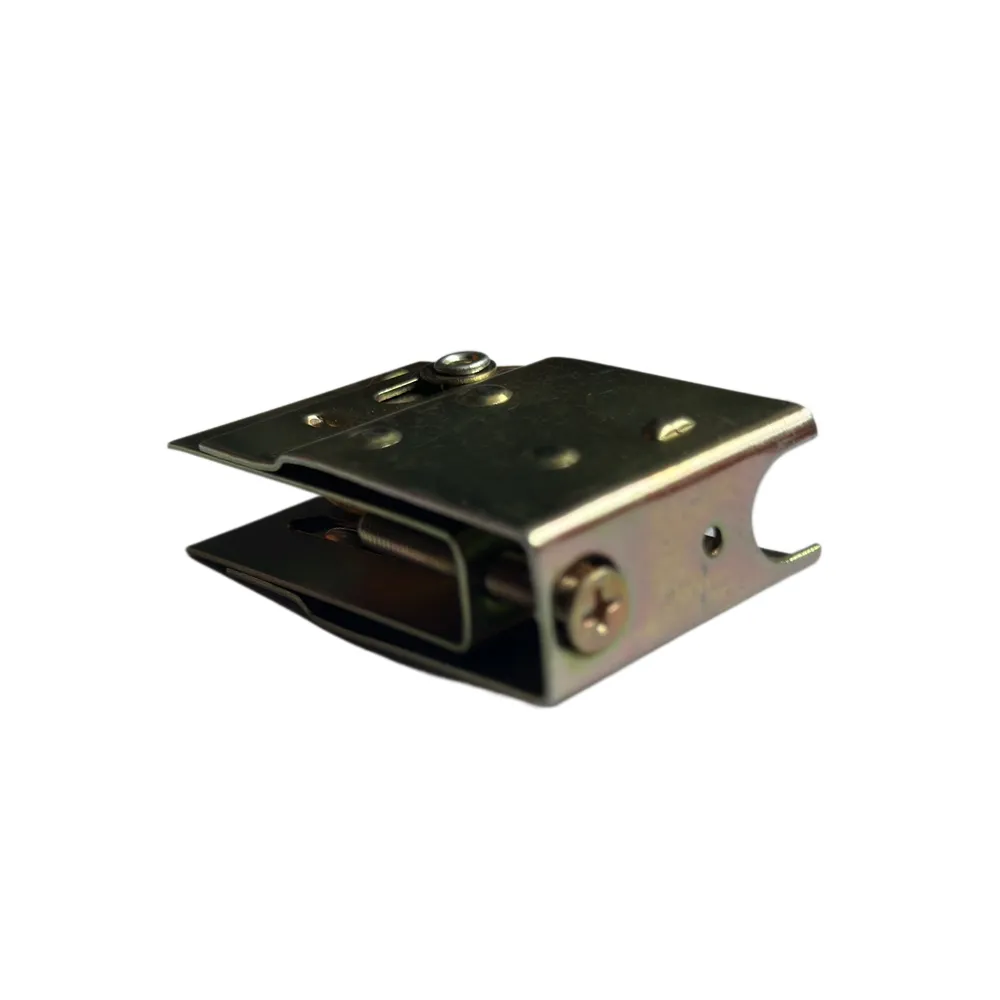

High-Quality Sliding Roller for Smooth Door Operation | Durable Housing Options

The sliding roller, a critical component enabling frictionless movement in various linear-motion systems, has seen vast developments in the past decade. From industrial automation to architectural applications, modern sliding roller technology—especially sliding roller with steel housing, aluminium sliding roller, and door sliding roller—delivers significant performance and energy-efficiency upgrades.

This comprehensive overview synthesizes the latest trends, core technical parameters, manufacturing processes, and market comparisons for the sliding roller industry. Supported by ISO/ANSI certifications, real-world client feedback, rigorous QC standards, and third-party benchmarks, this resource provides practitioners and procurement specialists with a trustworthy decision-making guide.

1. Sliding Roller Industry Trends 2024

Leading industry analytics show a strong surge in demand for high-precision sliding roller with steel housing and corrosion-resistant aluminium sliding roller components. Application areas such as petrochemical, metallurgy, automated doors, HVAC, and water management represent the fastest-growing segment. According to Grand View Research 2024, the global market value for advanced sliding and rolling elements is projected to reach USD 42.8 billion by 2027, with a CAGR of 6.2%.

“Up to 92% reduction in maintenance costs observed in industrial sites upgrading to EN ISO 9001-certified sliding roller systems.” — Industry Control Journal

2. Manufacturing Process: Full Breakdown

The modern sliding roller is manufactured through tightly controlled processes. Attention to geometry, surface roughness, and tolerance is vital for performance and durability. Below is a detailed, stepwise workflow for high-precision sliding rollers:

Material Selection

Select carbon steel, aluminium alloys (6061/6082), or stainless steel according to application.

Casting/Forging

Billets processed via investment casting (aluminium, steel) or precision forging (heavy-duty).

CNC Machining

Automated CNC lathes/mills ensure diameter tolerance (±0.01mm).

Surface Treat.

Surface hardening, zinc/nickel plating, or anodization (for aluminium sliding roller).

Assembly

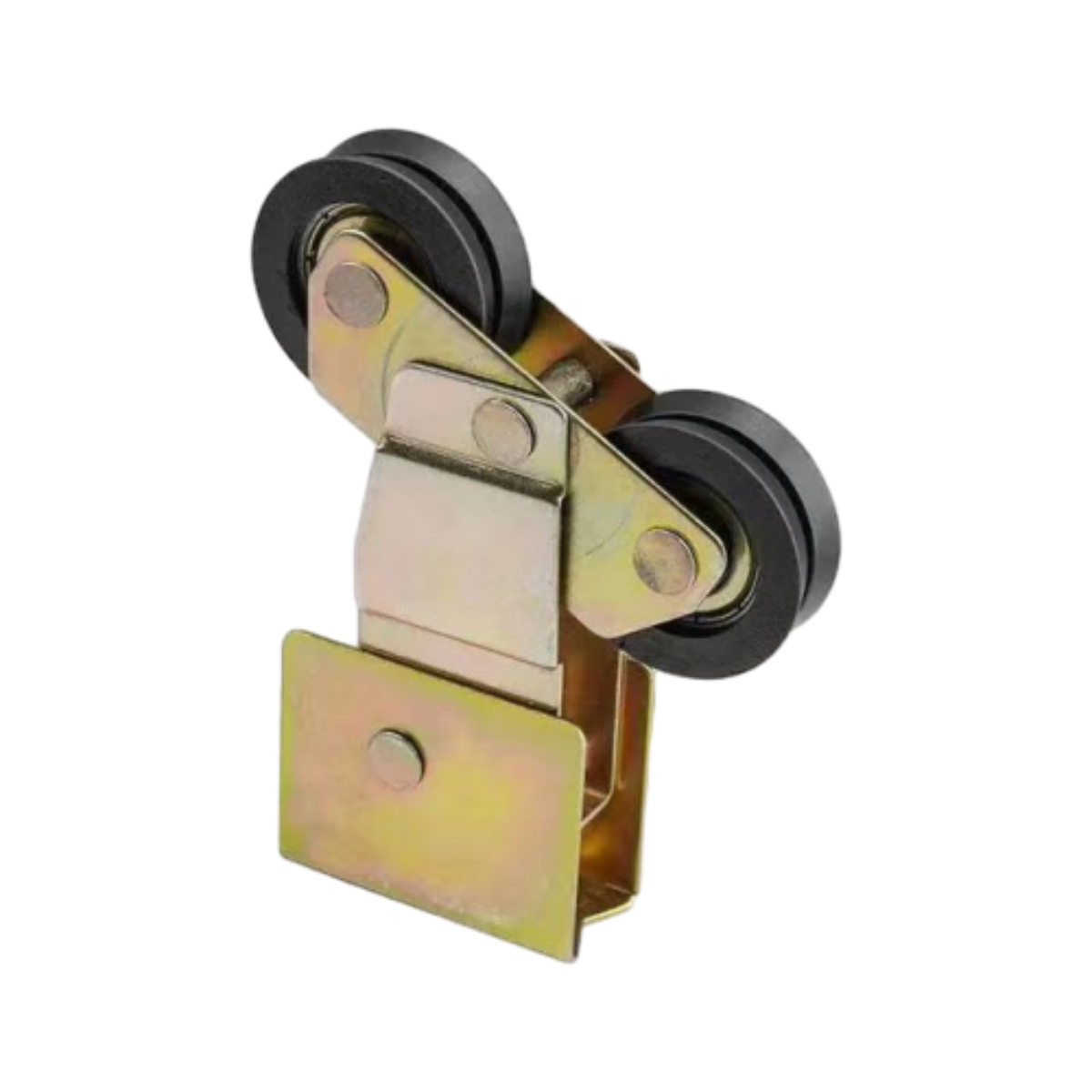

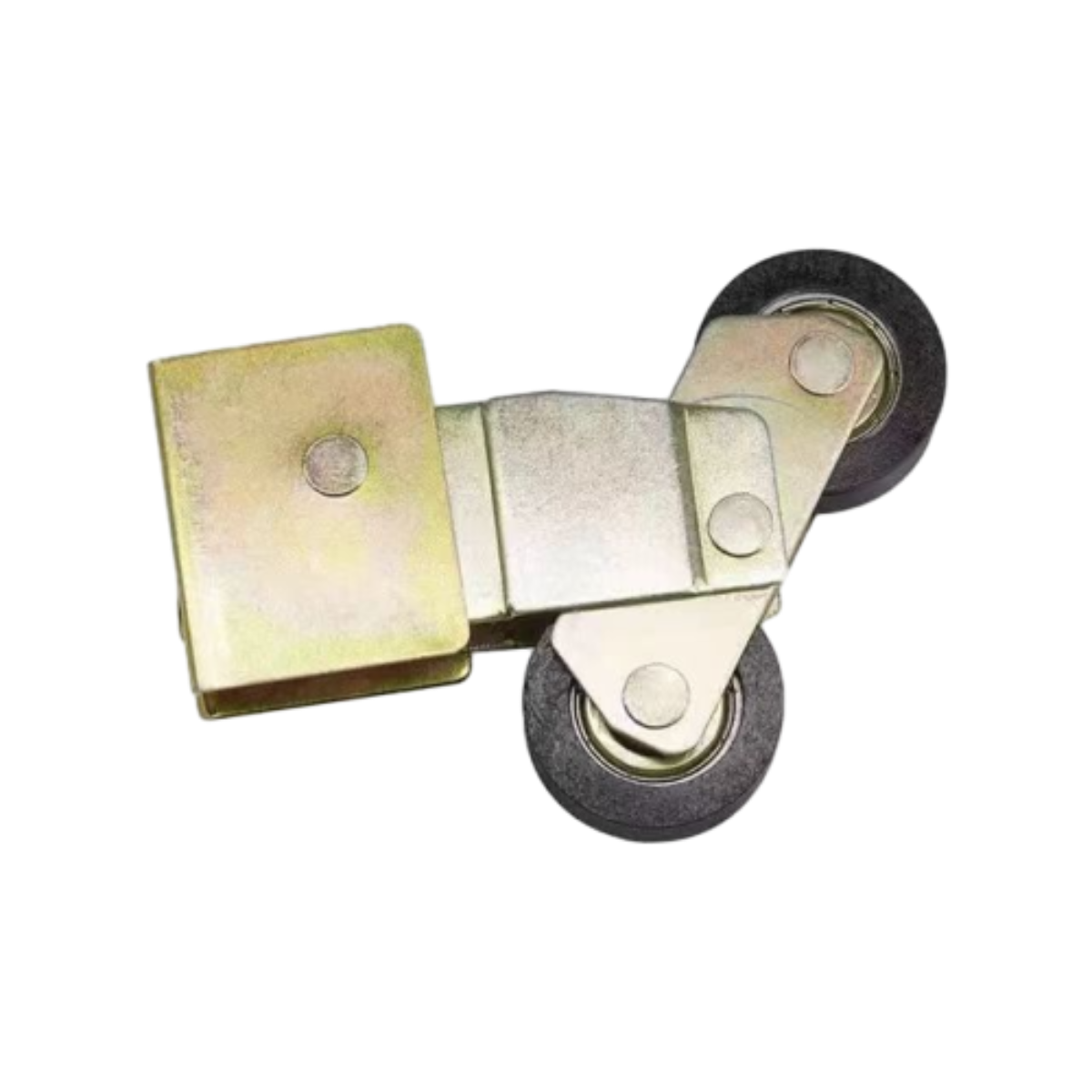

Press-fitted bearings, rubber seals, and steel/aluminum housing assembly.

QC & Test

ISO 2859 sampling, ANSI B18.22.1 mechanical/chemical tests.

- Steel Housing: High-load, shock-resistant, excellent lifespan in industrial sliding roller with steel housing solutions.

- Aluminium Alloy: Lightweight (35% weight reduction vs. steel), high corrosion resistance—widely used in aluminium sliding roller for doors.

- Bearings: Deep-groove or angular contact, life tested to over 50,000 cycles.

- Surface Finishing: Corrosion protection up to 720 hours salt-spray per ASTM B117.

3. Sliding Roller: Technical Specifications & Parameters

Specifying the correct sliding roller entails understanding several technical parameters:

| Type | Material | Load Capacity (kg) | Diameter (mm) | Surface Treatment | Certifications | Suitable Industries |

|---|---|---|---|---|---|---|

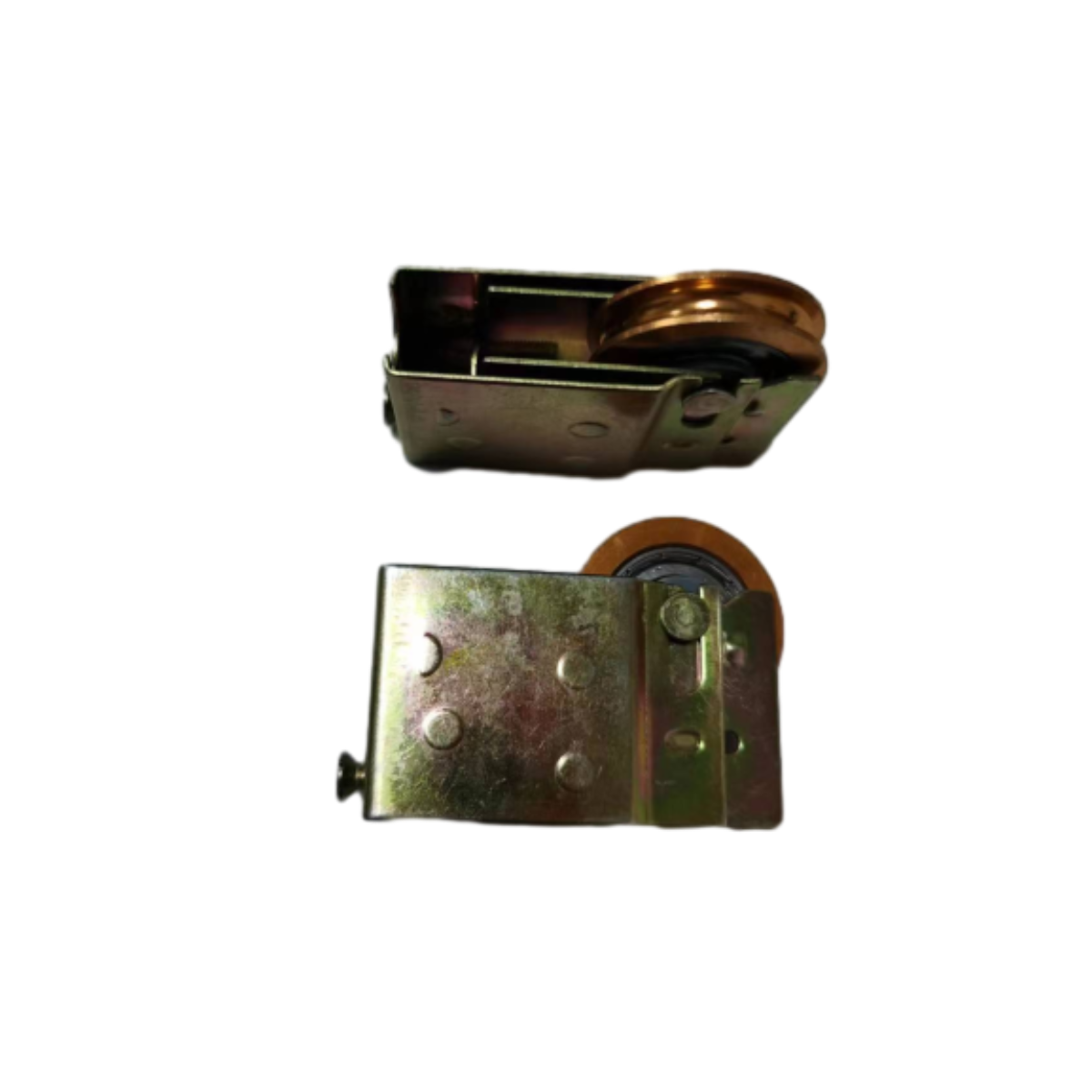

| sliding roller with steel housing | Carbon/Stainless Steel | 120–850 | 25, 32, 40, 50, 65 | Zinc/Nickel Plated | ISO 9001, ANSI B18.22.1 | Industrial, Mining, Logistics |

| aluminium sliding roller | 6061/6082 Aluminium Alloy | 35–320 | 25, 30, 38, 45, 55 | Anodized/Passivated | ISO 2768, ROHS | Doors, Windows, HVAC |

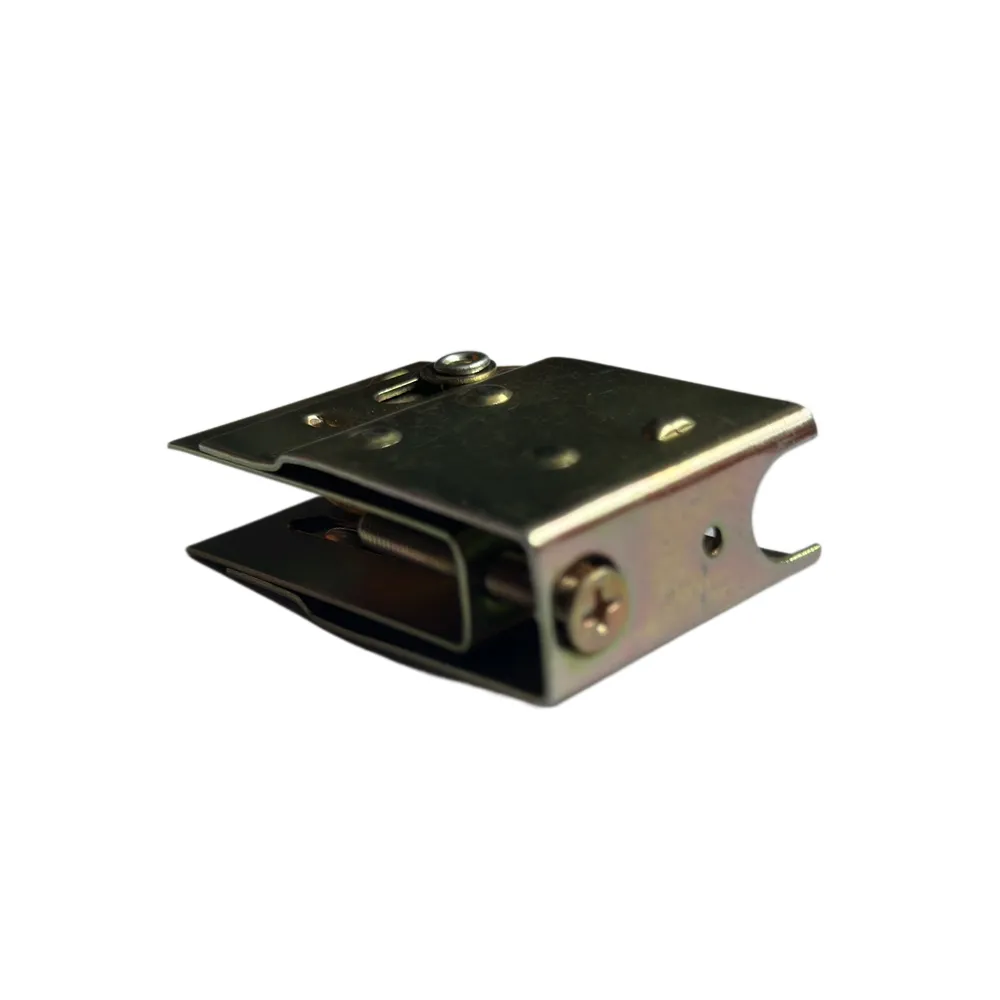

| door sliding roller | Steel/Aluminium/ABS | 15–95 | 18, 22, 25, 30 | Color Painted/Chrome | EN 1527, ISO 9001 | Residential, Commercial Doors |

Key Insights:

- Steel housing outperforms in mechanical load and cycle life (ideal in tough industrial settings).

- Aluminium sliding roller dominates for weight savings and corrosion protection, especially in high-humidity environments and glass doors.

- Door sliding roller prioritizes silence, smooth start torque and compactness for user comfort.

4. Sliding Roller vs. Market Alternatives

| Manufacturer | Main Material | Certifications | Typical Applications | Production Leadtime | QC Testing | Warranty |

|---|---|---|---|---|---|---|

| Tianjin JI Iron Casting (Pro) | Steel, Aluminium | ISO 9001, EN 1527, ROHS | Industry, Door/Window, Metrology | 18-35 days | 100% Inspection, ISO sampling | 18 months |

| G** Bearings | Steel | ISO 9001 | OEM, Industry | 28-45 days | Sample inspection | 12 months |

| D*** Corp | Aluminium | CE, EN 1527 | Doors, Light Duty | 32-40 days | Batch test | 12 months |

- Tianjin JI Iron Casting’s sliding roller leads the industry with advanced alloy selection and multi-standard compliance, delivering +20% operational lifespan (per factory study, 2023).

- Full supply-chain traceability and automated QC stations for all models.

- Comprehensive pre-sale/after-sale support with 30+ enterprise partners globally.

5. Customization & Engineering Service

Selecting the standard sliding roller might not be optimal for every application. Tianjin JI Iron Casting delivers fully customized design and engineering, tailored for demanding conditions:

- Custom dimensions, surface profiles, thread types, and lubrication choices.

- High-performance bearing/housing materials for acid, salt-fog, or extreme temperature environments (-30°C to +160°C).

- OEM and ODM support: Technical co-design, sample turnaround in 12 days.

- Engineering team with 15+ years experience, involved in over 520 international projects.

6. Application Scenarios & Case Study

- Challenge: Frequent roller failure due to high humidity and corrosive media.

- Solution: Deployed sliding roller with steel housing using ASTM A240 stainless, hard-chrome finish; internal bearings sealed to IP54.

- Results: Maintenance cost fell by ~72% (first 18 months); production uptime rose 4.7%.

- Certification: Third-party test (SGS, ISO 1527:2023) validated 51,000+ duty cycles without failure.

“Performance and lifespan of installed sliding roller units exceeded all metrics—zero field replacements since installation.” — Plant Maintenance Lead

Other Typical Use Cases

- High-speed warehouse doors: Quiet-operation door sliding roller units, tested at 70 dB max noise.

- Water treatment plants: Corrosion-proof aluminium sliding roller kits for environmental exposure.

- Logistics automation: Heavy-load steel sets supporting conveyor lines, >500,000 cycles lifespan with minimal oiling.

7. Quality, Delivery, and Service Commitment

| Delivery Cycle | Standard sliding roller: 18~35 days Custom solutions: 18~45 days |

|---|---|

| Warranty/Support |

|

| Certifications | ISO 9001, EN 1527, ROHS, ANSI B18.22.1, ASTM B117 (Salt-spray) |

| Endorsed By | Partnered with FDL, CNPC, YUEXIN Doors, Rotterdam Warehouse Solutions |

8. FAQ: Technical Expert FAQ for Sliding Roller

9. Further Reading & Authoritative References

- Industrial Bearings & Sliding Rollers Market 2024 Analysis – Grand View Research

- Choosing Rollers for Conveyor Applications – Control Engineering

- ISO 2859: Sampling and Testing Procedures

- Roller Material Best Practices – Autodesk Manufacturing Forum

- Performance Testing of Sliding Roller Systems – ResearchGate

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges