Choosing the Right Tension Rollers for Your Sliding Screen Door Spring Mechanism

Understanding Sliding Screen Door Spring Tension Rollers A Comprehensive Guide

Sliding screen doors are an essential feature in many homes, offering a transition between indoor and outdoor spaces while keeping bugs out. One of the crucial components that ensure the smooth operation of these doors is the spring tension roller. Understanding how these rollers work and how to maintain or replace them can greatly enhance the functionality of your sliding screen door.

What Are Spring Tension Rollers?

Spring tension rollers are mechanical devices located at the top or bottom of a sliding screen door. Their primary function is to allow the door to glide smoothly along its track. The roller's design incorporates a spring mechanism that provides the necessary tension, keeping the screen door securely in place while allowing it to be easily opened and closed. These rollers can typically be found in a range of materials, including plastic and metal, and they come in various sizes to fit different door designs.

How They Work

The operation of spring tension rollers is relatively simple. When you push or pull the sliding screen door, the rollers turn and glide along the track. The spring tension within the roller helps maintain contact with the track, ensuring that the door does not fall out of alignment. This mechanism allows for a seamless user experience, making it easy to open and close the door without excessive effort.

Common Issues with Spring Tension Rollers

Despite their simple design, spring tension rollers can encounter several issues over time. One of the most common problems is wear and tear. With regular use, the rollers can become worn down, leading to a rough or jerky sliding motion. Dirt and debris can also accumulate in the tracks or on the rollers, further complicating the door's operation.

Another issue is spring failure. If the internal spring becomes damaged or loses tension, the roller will not function correctly, which can result in the door being difficult to open or prone to falling off the track. In such cases, either the roller must be repaired or replaced.

Maintenance Tips

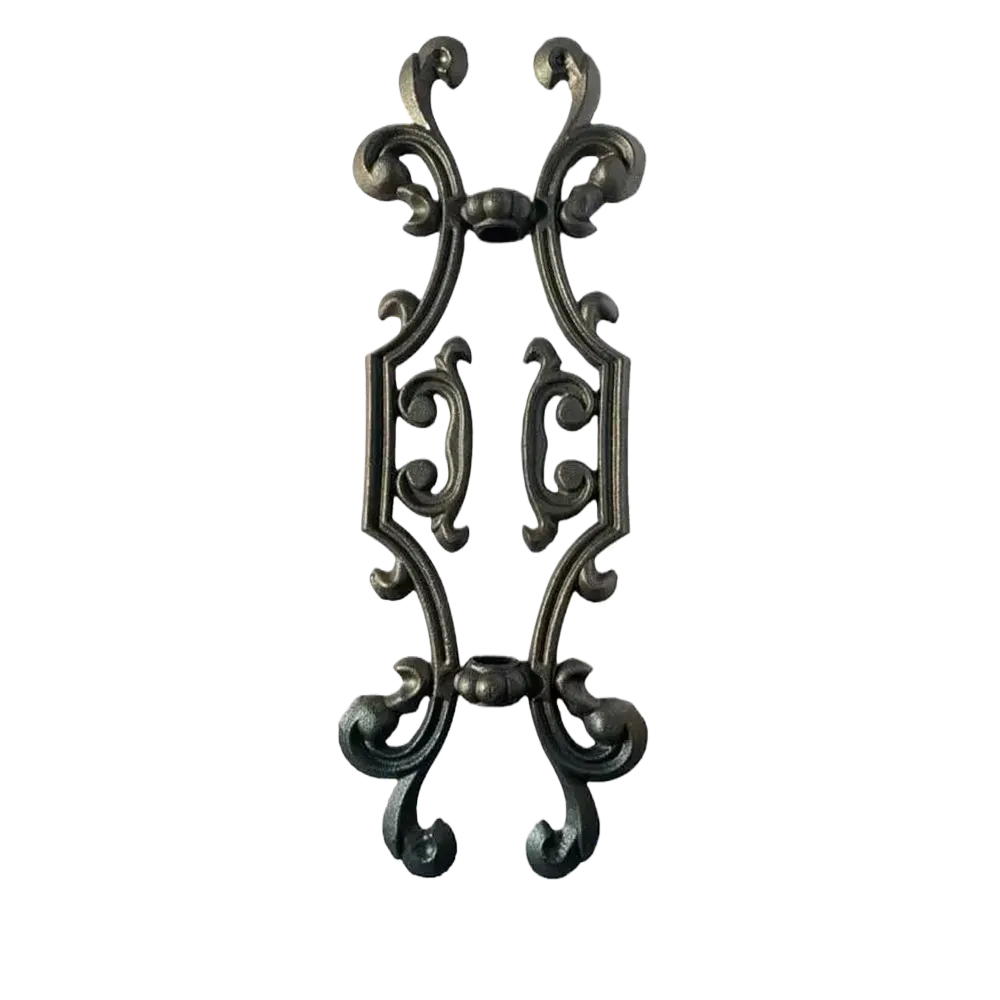

sliding screen door spring tension rollers

Regular maintenance is key to prolonging the life of your sliding screen door's spring tension rollers. Here are some simple tips to keep your doors functioning smoothly

1. Clean the Tracks Remove any dirt, leaves, or debris from the sliding tracks. This can be done using a vacuum cleaner or a soft brush.

2. Lubricate the Rollers Apply a silicone-based lubricant to the rollers and tracks. This will reduce friction and allow for a smoother glide.

3. Inspect Rollers Periodically Check the rollers for any signs of damage or wear. If you notice cracks, chips, or significant wear, consider replacing them to avoid further operational issues.

4. Adjust Tension If your door is sticking or not closing properly, the tension in the rollers might need adjusting. Consult the manufacturer’s instructions for guidance on how to do this safely.

Replacement of Spring Tension Rollers

If maintenance does not solve the issues, it may be time to replace the spring tension rollers. Replacement is often straightforward. Start by removing the screen door from its track following the manufacturer's guidelines. Next, take out the damaged rollers and replace them with new ones, ensuring they are compatible with your screen door model. Reinstall the door and test its operation.

Conclusion

Spring tension rollers are integral to the functionality of sliding screen doors. By understanding their operation and adhering to a regular maintenance schedule, you can enhance the longevity and performance of your screen door. Should issues arise, timely intervention—whether through cleaning, lubrication, or replacement—can keep your door sliding smoothly and effectively protecting your home from pests.

-

Why Choose Cast Iron for Your Next Project?NewsApr.27,2025

-

Timeless Charm of Cast Iron Decorative ElementsNewsApr.27,2025

-

Wholesale Cast Iron Products: A Growing Trend in Home and Garden DécorNewsApr.27,2025

-

The Advantages of Using Ornamental Cast Iron Parts in Your Design ProjectsNewsApr.27,2025

-

Why Ornamental Iron Castings Are Essential for Timeless DesignNewsApr.27,2025

-

The Elegance and Durability of Ornamental Cast Iron PanelsNewsApr.27,2025