Understanding the Advantages and Applications of Cast Iron Bushings in Various Industries

Understanding Cast Iron Bushings A Comprehensive Overview

Cast iron bushings are essential components in various mechanical applications, providing support, guidance, and durability to rotating shafts. Their unique properties make them an ideal choice for a wide range of industries, from automotive to manufacturing and beyond. This article will explore what cast iron bushings are, their advantages, applications, and the manufacturing processes involved in their production.

What Are Cast Iron Bushings?

Bushings are cylindrical sleeves that help reduce friction and wear between moving parts. Cast iron bushings are made from an alloy of iron, carbon, and other elements, giving them superior wear resistance and durability. The process of casting allows for intricate shapes and designs, which can be tailored for specific applications. These bushings can be lubricated or unlubricated, depending on the operating conditions and requirements of the machinery in which they are used.

Advantages of Cast Iron Bushings

1. Durability Cast iron is known for its toughness and ability to withstand high levels of wear and tear. This makes cast iron bushings particularly effective in high-stress environments where other materials might fail.

2. Excellent Wear Resistance The hardness of cast iron provides enhanced wear resistance, reducing the frequency of maintenance and replacement. This characteristic is crucial in applications where downtime can result in significant costs.

3. Cost-Effectiveness Compared to other materials like bronze or stainless steel, cast iron bushings are often more cost-effective, making them an attractive option for manufacturers looking to minimize production costs without sacrificing quality.

4. Vibration Damping Cast iron has excellent vibration-damping properties, which can lead to smoother operation in machinery, reducing noise and increasing the lifespan of other components.

5. Ease of Machining Although cast iron is tough, it is also relatively easy to machine. This adaptability allows for the production of custom bushings that meet specific design parameters, enhancing their utility in various applications.

Applications of Cast Iron Bushings

Cast iron bushings find utility in a multitude of applications across various industries

- Automotive Industry In vehicles, cast iron bushings are used in suspension systems, engine mounts, and various drive components to ensure smooth operation and longevity.

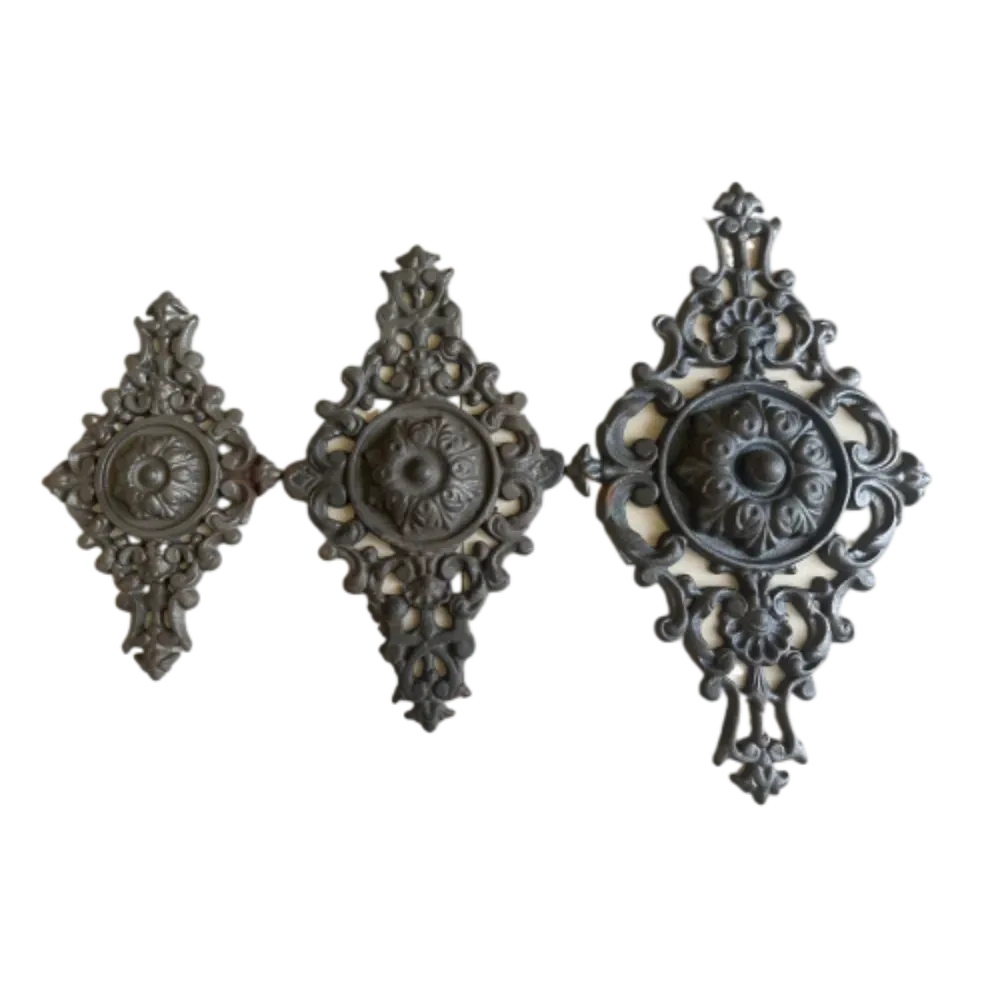

cast iron bushings

- Industrial Machinery Heavy machinery often employs cast iron bushings in their assemblies, including conveyor systems, gearbox housings, and hydraulic systems, where their durability is put to the test

.- Construction Equipment In construction machinery, such as excavators and bulldozers, cast iron bushings provide the necessary support while sustaining the immense forces generated during operation.

- Agricultural Equipment Tractors and other farming machinery rely on cast iron bushings to handle the harsh conditions and continuous operation experienced during agricultural tasks.

Manufacturing Process

The manufacturing of cast iron bushings typically involves several steps

1. Melting The process begins with melting the raw materials, including pig iron and scrap iron, in a furnace.

2. Pouring Once the metal is molten, it is poured into molds designed to create the desired bushing shape.

3. Cooling The castings are allowed to cool and solidify. This cooling process can significantly affect the properties of the final product.

4. Machining After cooling, bushings may need further machining to achieve precise dimensions and tolerances.

5. Inspection Finally, the bushings undergo quality control checks to ensure they meet industry standards before being shipped to customers.

Conclusion

Cast iron bushings play a pivotal role in diverse applications, thanks to their exceptional durability, wear resistance, and cost-effectiveness. Understanding the properties and manufacturing processes of these components can help industries make informed decisions about their use. As technology evolves, the role of cast iron bushings will likely continue to expand, reinforcing their importance in modern engineering and manufacturing processes.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters