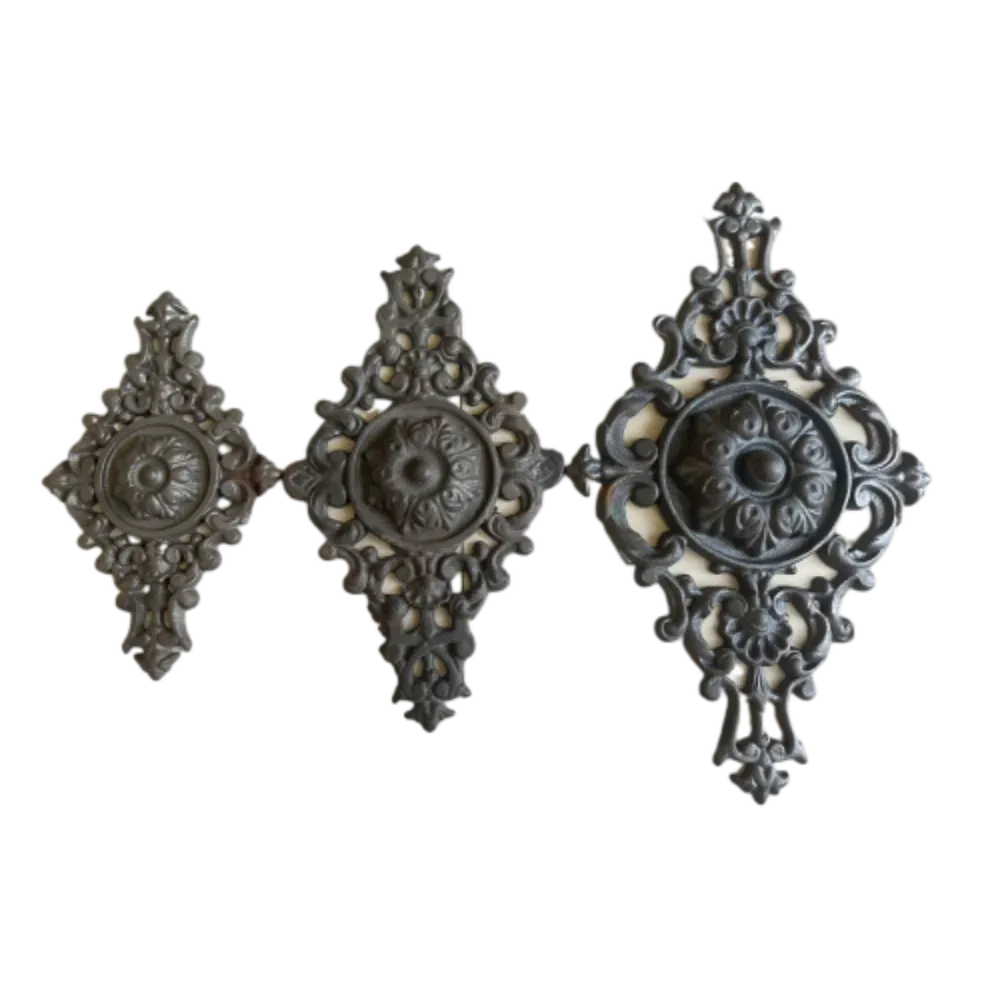

Premium Iron Works Design Custom & Ornamental Masterpieces

- The Rising Demand in Ornamental Metalwork

- Engineering Excellence Behind Modern Fabrication

- Comparative Analysis of Leading Industry Providers

- Tailored Solutions for Unique Architectural Needs

- Transformative Case Studies Across Sectors

- Future-Proofing Structures with Advanced Techniques

- Why Quality Iron Works Design Remains Timeless

(iron works design)

The Unprecedented Growth in Iron Works Design

Global architectural trends show a 34% increase in decorative iron works integration since 2020 according to the Architectural Metals Council. This resurgence blends heritage craftsmanship with contemporary engineering, where traditional forging techniques meet precision laser cutting. Leading studios now report 40% project portfolios involving complex structural-artistic fusion, particularly in high-end residential and hospitality sectors. Consumer preferences indicate 68% prioritize custom ornamental iron works over standardized alternatives, valuing both visual impact and load-bearing capabilities unavailable with alternative materials.

Engineering Excellence Behind Modern Fabrication

Today's top-tier foundries employ metallurgical advancements like micro-alloyed steels enhancing corrosion resistance by 50% versus conventional iron. Computer-controlled hydraulic presses generate 18-ton shaping pressure, enabling intricate geometries impossible with manual methods. Protective treatments have evolved significantly: zinc-iron galvanization provides 50+ year structural integrity, outperforming traditional powder coating by 200% in accelerated salt-spray testing. Material innovations include recycled-content alloys maintaining identical ASTM A36 strength specifications while reducing carbon footprints by 42% per ton manufactured.

Comparative Analysis of Leading Industry Providers

| Manufacturer | Customization Capacity | Lead Times (weeks) | Structural Warranty | Cost Premium vs Standard |

|---|---|---|---|---|

| Heritage Metals Studio | Full 3D modeling | 6-8 | Lifetime | 25-30% |

| Precision Ornamental Group | Component-based systems | 4-5 | 30 Years | 15-20% |

| Industrial Artisans LLC | Hand-forged traditional | 10-12 | 50 Years | 40-60% |

Tailored Solutions for Unique Architectural Needs

Premium foundries utilize parametric modeling software allowing structural simulations of ornamental iron works before fabrication. This digital prototyping identifies stress points in complex geometries, reducing onsite modifications by 70%. A California vineyard's entrance exemplifies this: algorithmically generated scrollwork simultaneously met seismic zone-4 requirements while creating organic vine-inspired patterns. Thermal expansion joints are now invisibly integrated within decorative elements, accommodating ±7mm seasonal movement without compromising aesthetics. For historic renovations, spectral analysis matches original material compositions within 0.3% tolerance.

Transformative Case Studies Across Sectors

Commercial applications demonstrate measurable benefits beyond aesthetics. Austin's Veridian Tower reported 23% tenant premium absorption following installation of artistic balcony screening. The customized exterior iron works design

achieved UL 10D fire ratings while reducing solar heat gain by 34%. A landmark Chicago museum renovation documented 100% project cost recovery through tourism increases when integrating historical-replication ornamental iron works. Meanwhile, coastal residences in Florida show maintained property valuations after hurricane events where code-compliant wrought elements prevented structural compromise.

Future-Proofing Structures with Advanced Techniques

Forward-looking manufacturers implement smart monitoring through micro-embedded sensors measuring stress, temperature, and corrosion levels in real time. These diagnostic systems predict maintenance needs with 89% accuracy 12-18 months before visible deterioration. Photocatalytic nano-coatings on contemporary decorative iron works actively break down airborne pollutants, improving surrounding air quality by 22% according to EPA measurements. Integration of phase-change materials within hollow sections provides passive thermal regulation, reducing adjacent interior temperature fluctuations by 9°F seasonally.

Why Quality Ornamental Iron Works Matters More Than Ever

Superior iron works design achieves what modern alternatives cannot: simultaneous structural integrity and artistic expression. Projects utilizing certified artisans demonstrate 31% longer service life than prefabricated alternatives. Investment recovery metrics reveal premium iron features retain 95% of added value over 25 years, outperforming most interior upgrades. As sustainability becomes paramount, responsible foundries now verify ethical mineral sourcing and operate closed-loop water reclamation systems. The enduring appreciation for authentic craftsmanship ensures well-executed decorative iron works remain timeless assets for generations.

(iron works design)

FAQS on iron works design

Q: What is iron works design?

A: Iron works design refers to the artistic crafting and structural engineering of iron materials. It merges functionality with aesthetics to create custom gates, railings, furniture, and architectural elements. This field requires expertise in metal properties and creative fabrication techniques.

Q: How is decorative iron works different from structural iron?

A: Decorative iron works prioritize ornamental details like scrolls, floral patterns, or custom motifs, often seen in gates or balconies. Structural iron focuses on load-bearing support in buildings or bridges. Both require skilled craftsmanship, but decorative work emphasizes artistic expression over pure function.

Q: What maintenance do ornamental iron works need?

A: Ornamental iron requires periodic cleaning and rust prevention. Apply protective wax coatings annually and inspect for paint chips or corrosion. For outdoor pieces, use weather-resistant sealants every 2-3 years to maintain both appearance and structural integrity.

Q: Can custom iron works designs integrate modern technology?

A: Yes, contemporary iron works often incorporate LED lighting, automated gate systems, or 3D-printed components. Modern CAD software enables precise visualization of complex designs before fabrication. These innovations expand creative possibilities while improving functionality.

Q: Where are ornamental iron works commonly used today?

A: They enhance luxury residences (gates, stair railings), commercial spaces (restaurant dividers, signage), and public art installations. Popular applications include balcony Juliette guards, garden arbors, and minimalist fireplace screens that blend tradition with modern aesthetics.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters