Choosing the Right Track for Door Rollers Installation and Maintenance

Understanding Track Door Rollers Functionality and Maintenance

Track door rollers are an essential component in various door systems, particularly sliding doors that require smooth and efficient movement. This article will explore the functionality of track door rollers, their types, common issues, and maintenance tips to ensure longevity and optimal performance.

Functionality of Track Door Rollers

Track door rollers function by enabling doors to slide open and closed along a track, providing a space-saving alternative to traditional swinging doors. These rollers are typically mounted on the top or bottom of the door and engaged with a track system that guides the door's movement smoothly. The primary materials used for rollers include plastic, nylon, and metal, each providing varying levels of durability, noise reduction, and weight capacity.

A well-designed track door roller system encompasses several key components, including the roller itself, the track, and the door frame. When installed correctly, the rollers reduce friction as the door moves, ensuring a quiet and effortless operation. In residential settings, track door rollers are commonly found in patio doors, closet doors, and bifold doors, while in commercial settings, they may be utilized in industrial sliding doors that require frequent access.

Types of Track Door Rollers

There are several types of track door rollers available, tailored for different applications. Some of the most common types include

1. Standard Rollers These are everyday rollers used in most residential sliding doors. Made of durable materials, standard rollers provide sufficient support and smooth operation.

2. Heavy-Duty Rollers Designed for larger or heavier doors, heavy-duty rollers are built to withstand increased weight and frequent use. They often come with reinforced bearings to support the heavy load.

3. Self-Adjusting Rollers These rollers can automatically adjust to accommodate slight changes in door height or track alignment, resulting in better performance over time.

track door rollers

Common Issues and Their Solutions

Despite their reliability, track door rollers can experience several problems over time. Understanding these issues can help homeowners and business owners take proactive measures.

1. Misaligned Track A common problem is a misaligned track, which can cause the rollers to skip or jump. Regular inspection of the track for any bends or obstructions is vital. If misalignment occurs, realignment or replacement of the track may be necessary.

2. Worn Rollers Over time, the rollers can wear out, leading to difficulties in door movement. Signs of wear might include noise during operation or visible damage to the rollers. In such cases, replacing the rollers with new ones can restore functionality.

3. Dirt and Debris Accumulation Dirt and debris can accumulate in the track and on the rollers, creating friction and hindering smooth movement. Regular cleaning of the track and rollers with a soft brush or vacuum can help maintain optimal performance.

4. Rust and Corrosion Metal rollers, in particular, are susceptible to rust and corrosion, which can severely compromise their integrity. Periodically inspecting metal components and applying rust inhibitors or lubricants can prolong their lifespan.

Maintenance Tips for Track Door Rollers

Maintaining track door rollers is essential for ensuring smooth operation and prolonging their life. Here are some maintenance tips

- Regularly inspect the track and rollers for any signs of wear or damage. - Keep the track free of debris and dirt through routine cleaning. - Lubricate the rollers and track with appropriate lubricants to reduce friction. - Ensure that the door is properly aligned and balanced to prevent undue stress on the rollers. - Consider replacing rollers at the first sign of any significant wear or damage before it affects the entire door system.

In conclusion, track door rollers play a crucial role in the functionality of sliding doors, offering ease of use and aesthetic appeal. By understanding their operation and conducting regular maintenance, you can avoid common issues and ensure your track door system remains in excellent condition for years to come. Whether in a home or commercial space, prioritizing the upkeep of track door rollers will ultimately lead to a more functional and pleasant environment.

-

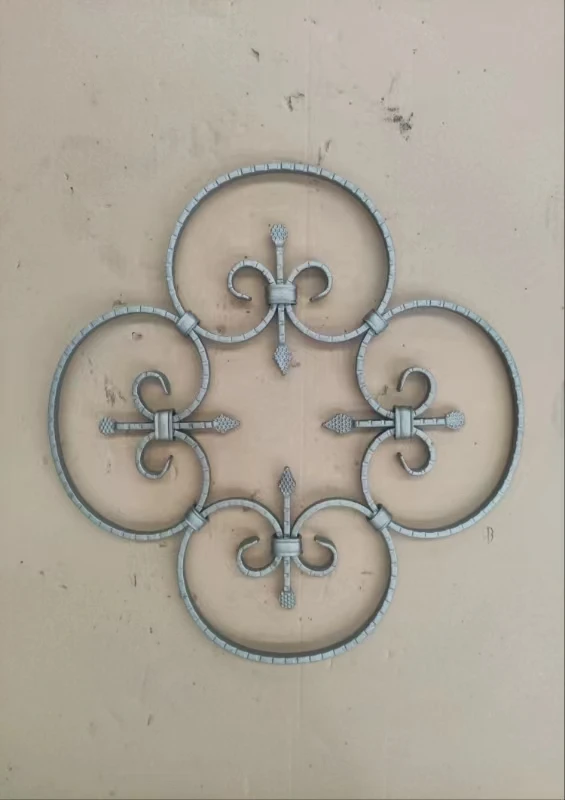

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters