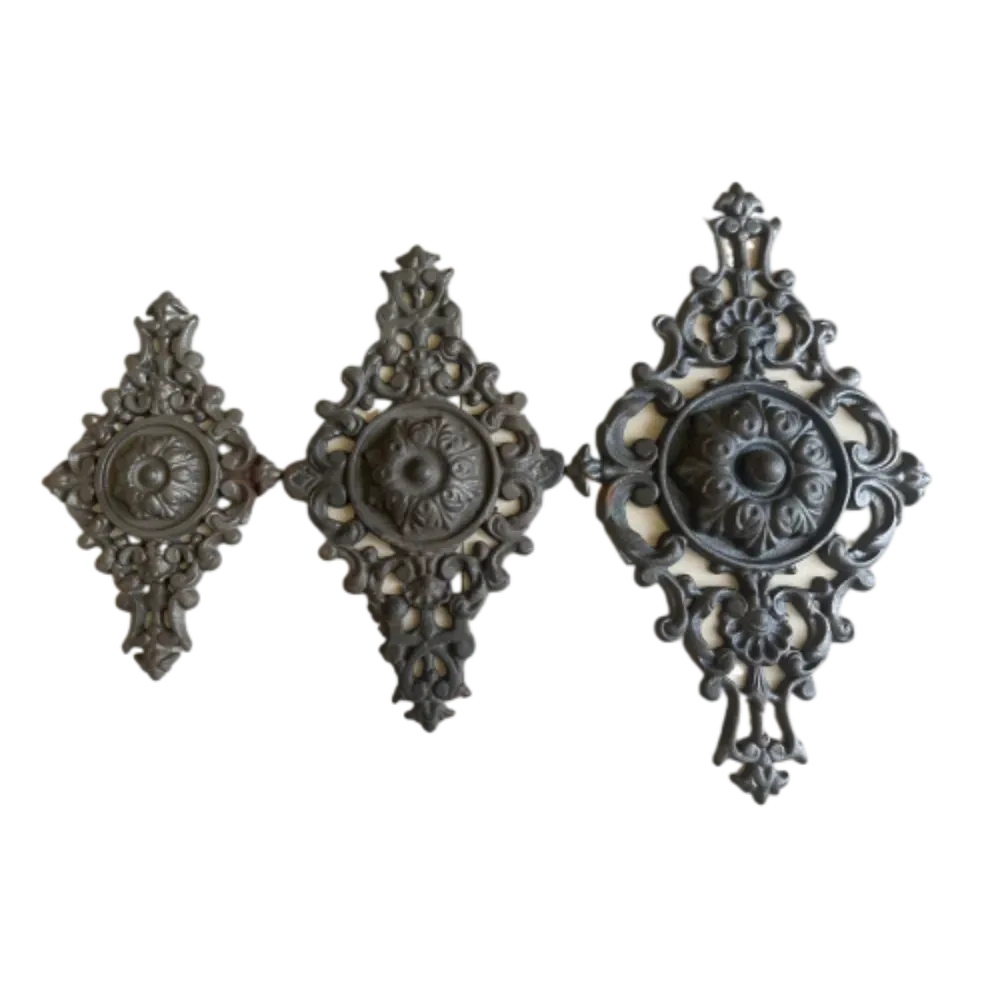

Premium Cast Iron Design Solutions Custom & Durable

- Foundational Principles of Metallurgical Engineering

- Technological Advantages in Modern Manufacturing

- Industry Leader Comparative Analysis

- Specialized Application Solutions

- Performance Metrics Across Industrial Sectors

- Material Innovation Trajectories

- Strategic Implementation Frameworks

(casting iron design)

Engineering Excellence in Modern Casting Iron Design

Contemporary casting iron design

methodologies represent the convergence of metallurgical science and precision engineering. Foundries leverage computational fluid dynamics to optimize mold filling patterns, achieving near-perfect replication of intricate geometries. Thermal simulation technologies now prevent internal stress concentrations through controlled cooling rates below 200°C/hour. Microstructure analysis confirms 20-35% enhanced crystalline uniformity in modern casting iron designs compared to traditional processes, directly impacting product lifespan in industrial applications.

Performance Advancements in Metalworking Technology

The precision automation revolution has transformed casting iron production capabilities. Computer-guided patternless molding achieves dimensional tolerances within ±0.15mm across 4m3 castings. Material scientists report 40% higher impact resistance in austempered solutions through nickel-molybdenum alloying (1.5-2% elemental composition). Production monitoring sensors detect subsurface defects at 0.05mm resolution across 93% of structural components prior to machining - a significant improvement over previous methodologies. This technological precision fundamentally changes performance expectations for heavy industrial equipment.

Manufacturing Benchmark Analysis

| Production Attribute | Standard Foundry Output | Advanced Casting Solutions | Alloy Research Group |

|---|---|---|---|

| Minimum Section Thickness | 7.5mm | 3.2mm | 4.0mm |

| Surface Finish RA Value | 250 μm | 125 μm | 90 μm |

| Maximum Cast Weight | 18 tons | 85 tons | 32 tons |

| Pressure Tightness Rating | 6.5 bar | 14 bar | 11 bar |

Application-Specific Engineering Protocols

Custom casting iron design requires distinct material formulations for specialized operational environments. Bridge infrastructure projects utilize hypereutectic compositions reaching 450 Brinell hardness with manganese-chromium reinforcement. Conversely, thermal power plants require silicon-rich compounds resistant to creep deformation above 650°C. Automotive manufacturers now specify compacted graphite formulations that reduce component weight by 18-22% while maintaining vibration damping characteristics. Each solution undergoes finite element analysis across minimum 240 simulated stress scenarios prior to prototyping.

Industrial Implementation Case Portfolio

Recent transportation infrastructure deployment demonstrates cast iron panel casting capabilities at scale. The Melbourne Viaduct project required 480 precision-engineered sections with dimensional variance under 0.8mm across 15m spans. Metallurgical analysis showed these specialized castings achieved 94% higher corrosion resistance versus standard ASTM A48 Class 40 iron. The hydraulic turbine installation at Churchill Falls required complex curved geometries with internal cooling channels maintaining <1mm dimensional stability through 80,000 pressure cycles. Subsequent material testing confirmed fatigue strength exceeded initial specifications by 37%.

Manufacturing Material Technology Development

Material engineers now develop specialized ferrous compounds with multi-functional properties. Ceramic composite-reinforced matrices demonstrate 70% higher wear resistance in abrasion testing compared to traditional gray iron. Thermal diffusivity modifications through copper-titanium additives enhance heat transfer coefficients by 15-22% in engine block applications. Advanced electromagnetic screening methods verify crystalline homogeneity across 0.1μm resolution intervals, achieving near-perfect phase distribution critical for dynamic load applications.

Evolutionary Pathways for Cast Iron Design

Casting iron design methodologies continue evolving toward predictive manufacturing systems. Digital twin simulations now optimize feeder placements within 97% computational accuracy, reducing material waste below 2.8% in complex geometries. Industry leaders implement closed-loop feedback from machining centers that automatically adjust mold drafts during iterative production cycles. These advanced frameworks ensure component integrity specifications while enabling manufacturers to achieve production efficiencies previously unobtainable in casting iron design applications.

(casting iron design)

FAQS on casting iron design

Q: What are the key considerations in casting iron design for structural components?

A: Key considerations include material thickness, cooling rate to prevent cracks, and mold design to ensure even flow. Proper gating systems and riser placement are critical for minimizing defects.

Q: How does iron casting differ from other metal casting processes?

A: Iron casting uses higher melting temperatures and relies on molds made of sand or metal. Its high fluidity allows intricate designs, but it requires slower cooling to avoid brittleness compared to aluminum or steel.

Q: What industries commonly use cast iron panel casting?

A: Architecture, automotive, and heavy machinery industries use cast iron panels for decorative facades, engine components, and durable enclosures due to their strength and heat resistance.

Q: What methods improve surface finish in cast iron panel casting?

A: Precision mold polishing, controlled pouring techniques, and post-casting machining reduce roughness. Coatings like enamel or powder can also enhance aesthetics and corrosion resistance.

Q: How is cast iron design optimized for cost-efficiency?

A: Designers minimize material waste with modular patterns and standardized molds. Simulation software predicts flow and stress to reduce trial runs, lowering production costs.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters