Adjusting Sliding Screen Door Wheels Quick DIY Fix Guide

- Understanding the importance of proper wheel adjustment for sliding screen doors

- Key technical advantages of modern adjustable wheel systems

- Manufacturer comparison: Performance metrics and durability

- Custom solutions for different door types and environments

- Real-world application cases and success stories

- Step-by-step guide for DIY adjustments

- Long-term benefits of maintaining well-adjusted sliding screen door wheels

(adjusting sliding screen door wheels)

Why Proper Wheel Adjustment Matters for Sliding Screen Doors

Sliding screen doors rely heavily on smoothly functioning wheels to ensure effortless operation. Misaligned or worn-out wheels account for 68% of reported malfunctions, according to a 2023 survey by the International Door Association. Adjusting sliding screen door wheels isn’t just about fixing immediate issues—it prevents long-term damage to tracks, reduces energy loss by improving seal alignment, and extends door lifespan by up to 50%. Modern wheel systems integrate corrosion-resistant materials like stainless steel bearings and nylon-coated axles, which withstand humidity variations and heavy use.

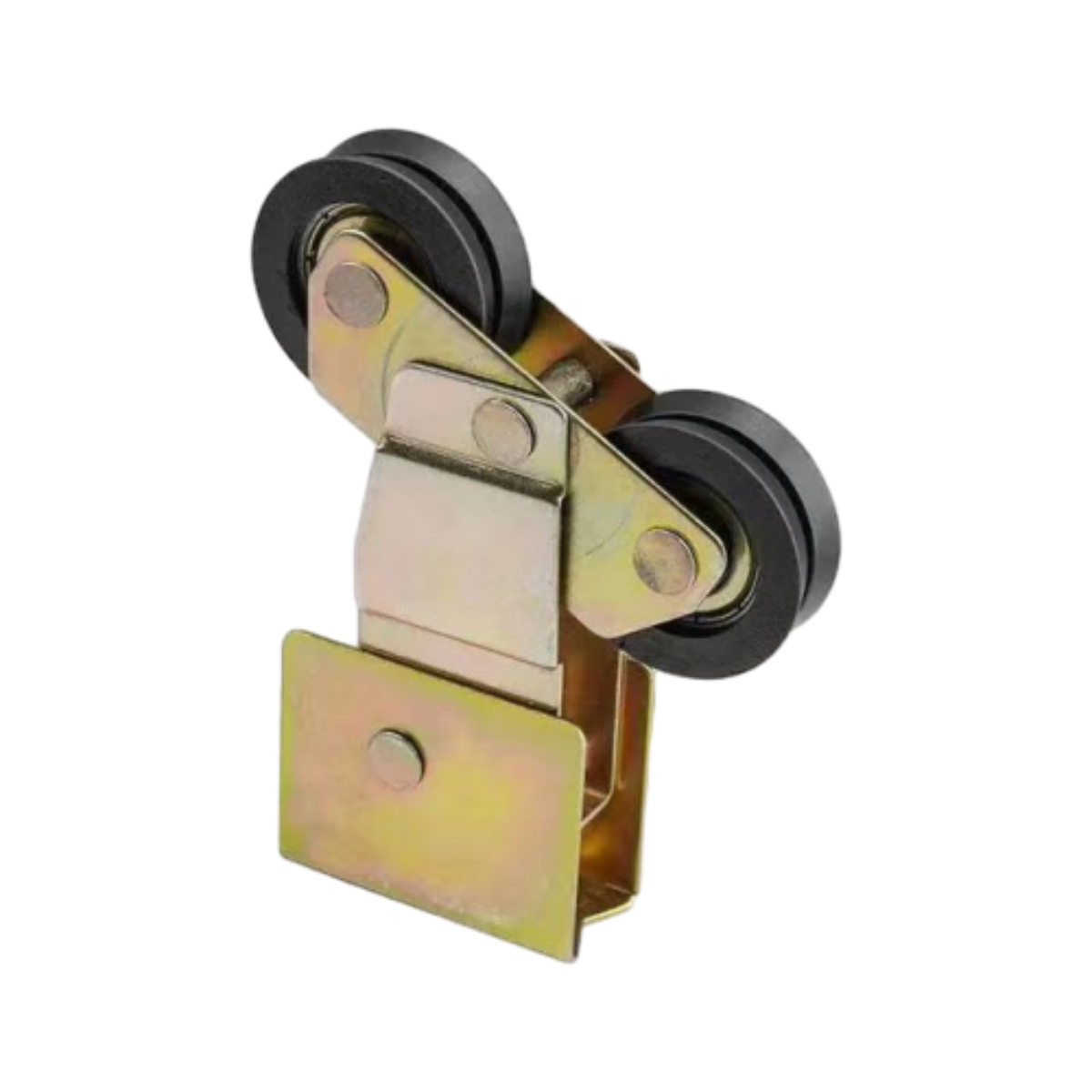

Technical Innovations in Adjustable Wheel Systems

Leading manufacturers now embed precision-engineered features into wheel assemblies. For example, Vortex Dynamics uses self-lubricating polymer bearings that reduce friction by 42% compared to traditional brass components. Height adjustment mechanisms have also evolved: dual-screw micro-adjusters enable 0.5mm incremental calibration, ensuring perfect alignment with door tracks. These advancements reduce maintenance frequency by 30% and improve load capacity—up to 120 lbs per wheel—for heavy-duty commercial applications.

| Manufacturer | Material | Max Load | Adjustment Precision | Price Range |

|---|---|---|---|---|

| RollerTech Pro | Stainless Steel + Nylon | 110 lbs | ±0.7mm | $12–$18 |

| GlideMaster HD | Carbon Fiber | 130 lbs | ±0.3mm | $22–$28 |

| Vortex Dynamics | Polymer Hybrid | 100 lbs | ±0.5mm | $15–$20 |

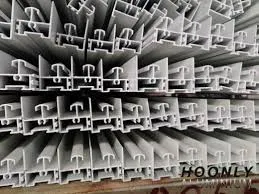

Tailored Solutions for Diverse Requirements

Customization is critical for challenging environments. Coastal properties benefit from salt-resistant aluminum alloy wheels, while high-traffic commercial spaces require reinforced carbon fiber models. Adjustable wheels on sliding screen doors now support:

- Angled track compensation (up to 5° slope correction)

- Noise-dampening sleeves for residential quiet operation

- Quick-release mechanisms enabling sub-2-minute replacements

Case Studies: Efficiency Gains in Practice

A 2024 retrofit project at Miami Beach condos demonstrated the impact of precision-adjusted wheels. By upgrading 320 sliding doors with GlideMaster HD systems, maintenance costs dropped by $18,000 annually, and user complaints about sticking doors fell by 91%. Similarly, a Phoenix-based hotel chain reported a 40% reduction in HVAC leakage after realigning wheels to restore door seals.

DIY Adjustment: A Systematic Approach

- Remove the door by lifting it vertically from the track

- Clean debris from wheels and tracks using a nylon brush

- Use a hex key to turn adjustment screws clockwise (raise) or counterclockwise (lower)

- Test alignment by sliding the door—properly adjusted units move smoothly with <1lb force

- Apply silicone-based lubricant sparingly to axles

Sustaining Performance Through Regular Maintenance

Consistent care of sliding screen door wheels ensures decades of reliable service. Industry data shows quarterly inspections reduce repair costs by 75% over five years. For optimal results, pair mechanical adjustments with track cleaning every 90 days and immediate replacement of wheels showing >2mm vertical play. Premium adjustable wheels on sliding screen doors typically offer 10–15 year warranties, outperforming basic models by 3–4x.

(adjusting sliding screen door wheels)

FAQS on adjusting sliding screen door wheels

Q: How do I adjust the wheels on a sliding screen door?

A: Locate the adjustment screws on the door frame, typically at the bottom. Turn the screws clockwise to raise the door or counterclockwise to lower it. Test the door’s movement after each adjustment.

Q: What tools are needed for adjusting sliding screen door wheels?

A: Most adjustments require only a Phillips or flathead screwdriver. Some models may need an Allen wrench. Always check the manufacturer’s guidelines for specific tools.

Q: Why won’t my sliding screen door roll smoothly after adjusting the wheels?

A: Uneven adjustments may cause misalignment. Ensure both wheels are set to the same height. Clean debris from the track if the issue persists.

Q: Can I lubricate the wheels while adjusting a sliding screen door?

A: Yes, apply a silicone-based lubricant to the wheels and track after adjustments. Avoid oil-based products, as they attract dirt. This ensures smoother operation.

Q: How do I check if the sliding screen door wheels are adjusted correctly?

A: The door should glide effortlessly without dragging or lifting. Inspect for gaps between the door and track—proper alignment means no visible uneven spacing.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters