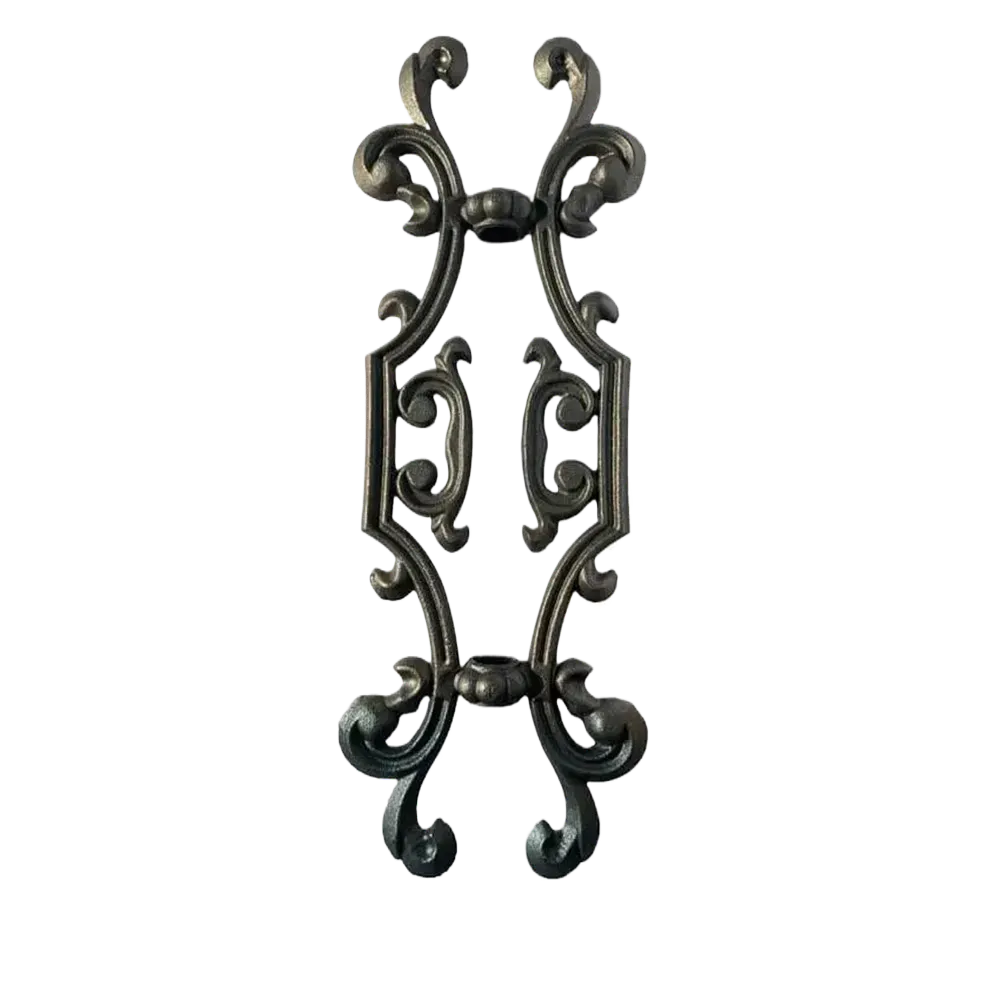

cast iron panel casting

The Art of Cast Iron Panel Casting

Cast iron panel casting is a fascinating process that blends art and engineering to create robust, durable, and aesthetically appealing components for various applications, from architectural elements to industrial machinery. This method of casting involves pouring molten iron into a mold, where it solidifies, taking on the shape and characteristics of the mold. The properties of cast iron, particularly its excellent castability, wear resistance, and thermal stability, make it an ideal material for a wide range of products.

The Process of Cast Iron Panel Casting

The journey of creating cast iron panels begins with selecting the right type of iron. Typically, gray iron, ductile iron, or white iron is used, each offering unique properties suited for specific applications. The casting process itself can be divided into several key stages mold preparation, melting, pouring, and cooling.

1. Mold Preparation The first step is to create a mold that reflects the desired shape of the panel. This can be made of sand, metal, or ceramic, depending on the complexity and surface finish required. For detailed designs, sand molds are often preferred due to their ability to capture intricate features.

2. Melting Once the mold is ready, the casting iron is melted in a furnace at high temperatures, typically around 1200 to 1500 degrees Celsius. The molten iron must reach a homogeneous state, ensuring that any impurities are eliminated, which is vital for the quality of the final product.

3. Pouring After melting, the molten iron is carefully poured into the prepared mold. This step requires precision, as pouring too quickly can lead to defects such as air pockets or incomplete filling of the mold. The temperature and flow rate of the molten iron are closely monitored to ensure a smooth casting process.

cast iron panel casting

4. Cooling After pouring, the cast iron panels are left to cool gradually. This cooling process is crucial, as it affects the material’s properties. Rapid cooling can result in brittleness, whereas slow cooling allows for a more uniform microstructure, enhancing toughness and durability.

5. Finishing Once the panels have cooled and solidified, they are removed from the mold and undergo finishing processes. This may include machining, grinding, or painting to achieve the desired surface quality and dimensions. The final product is then rigorously inspected for defects and compliance with specifications.

Applications and Benefits

Cast iron panels are widely used in various sectors, including construction, automotive, and manufacturing. Their strength makes them suitable for heavy-duty applications, while their aesthetic appeal allows them to be used in decorative elements, such as gates, railings, and architectural facades.

One of the outstanding benefits of cast iron is its ability to absorb vibrations and noise, making it a sought-after material in building construction and machinery components. In addition to their mechanical advantages, cast iron panels are resistant to corrosion, particularly when coated, which extends their lifespan even in harsh environments.

In conclusion, cast iron panel casting is an integral process in modern manufacturing that combines traditional craftsmanship with advanced technology. The careful selection of materials, meticulous attention to detail, and a thorough understanding of the casting process contribute to the creation of strong, reliable, and beautiful cast iron panels that meet the demands of various industries. As technology continues to advance, the applications and techniques of cast iron panel casting are likely to evolve, further enhancing its value in the marketplace.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters