Exploring the Mechanics and Benefits of Sliding Roller Systems in Modern Applications

The Sliding Roller Revolutionizing Motion and Efficiency

In the realm of mechanical engineering and material handling, the sliding roller has emerged as an innovative solution that enhances efficiency and simplifies operations across various industries. This seemingly simple device transforms the way objects are moved, reducing friction and effort while improving productivity. By delving deeper into the mechanics, applications, and the future potential of sliding rollers, we can appreciate their significance in modern technological advancements.

At its core, the sliding roller operates on a principal mechanism of reducing friction between two surfaces. Traditionally, moving heavy or bulky items required considerable force and effort, often leading to wear and fatigue. The introduction of sliding rollers—a cylindrical component that rolls underneath objects—has mitigated this challenge. By providing a smooth surface over which an object can glide, these rollers minimize contact friction significantly. This reduction in resistance allows for easier manipulation of heavy loads, making tasks that once required multiple personnel or complex machinery now achievable by a single individual.

Sliding rollers are particularly beneficial in industries such as construction, warehousing, and logistics. For instance, in a warehouse setting, sliding rollers are often implemented on conveyor belts and loading docks, facilitating the transport of packages and goods with minimal physical strain. Workers can effortlessly slide heavy boxes across the platform, thereby improving workflow and reducing the risk of workplace injuries. Similarly, in construction, sliding rollers simplify the movement of heavy materials, such as steel beams or concrete slabs, allowing for more efficient assembly and installation processes.

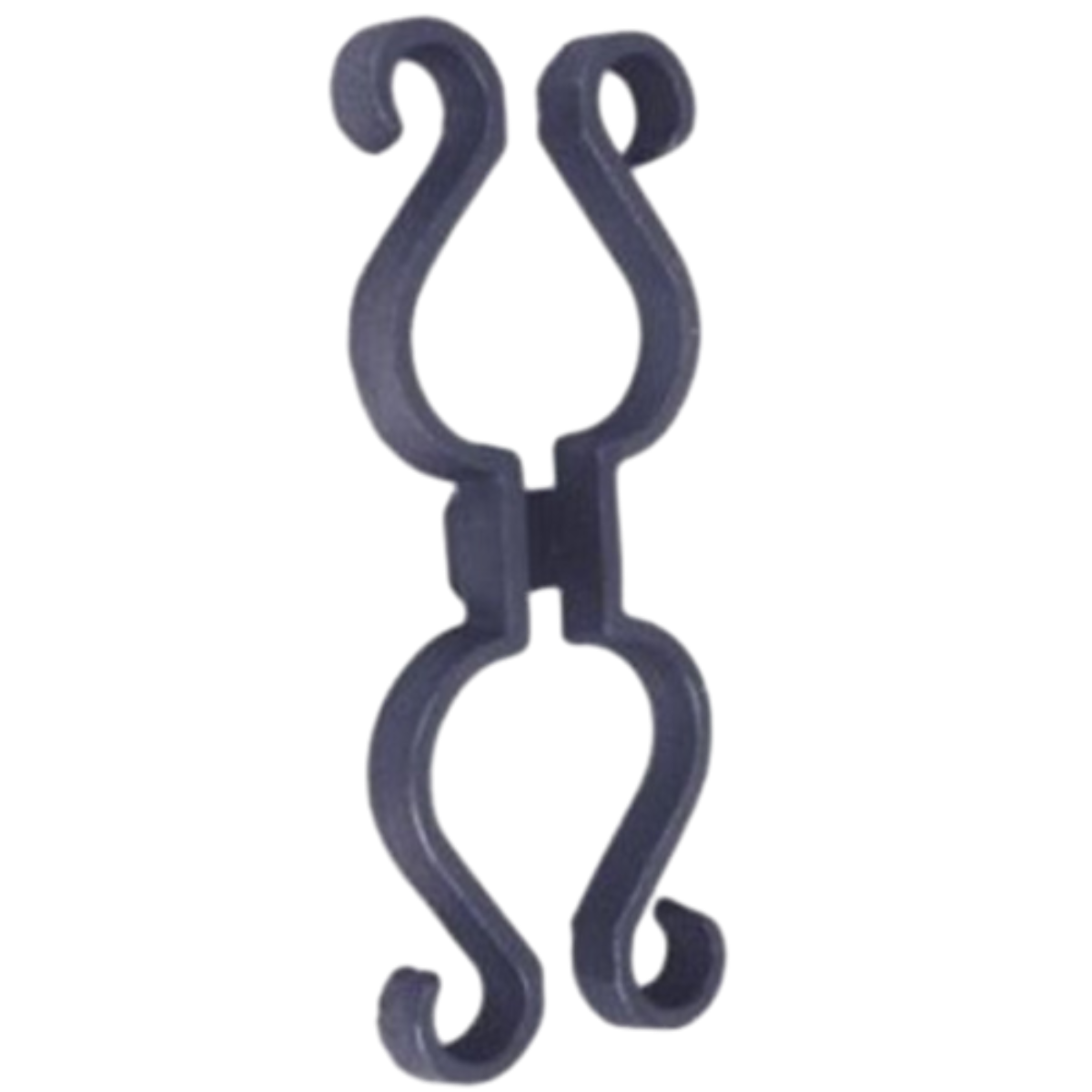

sliding roller

Beyond traditional applications, the design and functionality of sliding rollers have evolved. Advanced materials, such as high-density polyethylene or specially designed rubber, enhance the performance and durability of these rollers. Innovations in bearing technology have further improved their efficiency, allowing for smoother movements and reduced maintenance requirements. Additionally, modern sliding rollers can be customized for specific tasks, offering variable sizes, load capacities, and even non-slip surfaces for enhanced stability and grip.

Moreover, the integration of technology into the design of sliding rollers is paving the way for smarter solutions. For instance, with the incorporation of IoT (Internet of Things) capabilities, these devices can be monitored in real-time, providing valuable data on usage patterns and wear. Such insights can lead to predictive maintenance, minimizing downtime and prolonging the lifespan of equipment. As industries increasingly shift towards smart manufacturing and automation, the role of sliding rollers will undoubtedly expand, becoming integral components of automated systems and robotics.

Looking ahead, the potential of sliding rollers extends beyond their current uses. The ongoing quest for sustainable solutions may lead to the development of eco-friendly sliding rollers crafted from biodegradable materials or designed for energy-efficient operations. Furthermore, with the emphasis on reducing workplace injuries and enhancing ergonomics, sliding rollers can play a pivotal role in creating safer work environments, aligning with the growing trend of health-conscious workplace practices.

In conclusion, the sliding roller may seem like a humble device, but its impact on efficiency and safety in industrial applications is profound. As technology continues to evolve, so too will the capabilities of sliding rollers. We can expect even greater innovations that will further enhance their performance, integrating them more closely with smart technologies and sustainable practices. Embracing these advancements not only boosts productivity but also fosters a more efficient and innovative future across various sectors.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters