Sliding Screen Door Roller Replacement Solutions for Smooth Operation

Sliding Screen Replacement Rollers A Complete Guide

Sliding screens are a common feature in many homes, designed to provide ventilation while keeping insects at bay. Over time, the rollers that allow these screens to glide smoothly can wear out, leading to frustration and inconvenience. Replacing sliding screen rollers may seem daunting, but it is a manageable DIY project with the right tools and knowledge. This guide will walk you through the importance of screen rollers, signs of wear, and the replacement process.

Understanding Sliding Screen Rollers

Sliding screen rollers are the small wheels that enable the screen to move smoothly along the track. They play a crucial role in the operation of the screen door or window, ensuring that it can open and close easily. There are various types of rollers depending on the manufacturer and design of the screen, including ball-bearing, plastic, and metal options. Knowing the type of roller you have is essential for choosing the correct replacement.

Signs of Wear

Before starting the replacement process, it's important to recognize the signs that your sliding screen rollers need replacement. Common indicators include

1. Difficulty Opening or Closing If your screen drags or gets stuck when opening or closing, it may indicate worn-out rollers. 2. Noise Squeaking, grinding, or rattling noises can signal that the rollers or track are damaged. 3. Misalignment If your screen is misaligned or not fitting into the frame correctly, it may be due to faulty rollers. 4. Physical Damage Inspect the rollers for cracks, chips, or excessive wear. If they appear damaged, they will likely need replacement.

Preparing for Replacement

Before replacing the rollers, gather necessary tools and materials

- Screwdriver (typically a Phillips head) - Replacement rollers (make sure to match them to the old ones) - Lubricant (optional, for the track) - Cleaning supplies (to clean the track)

Steps to Replace Sliding Screen Rollers

sliding screen replacement rollers

1. Remove the Screen Start by carefully lifting the screen out of the frame. You may need to unscrew the screen or tilt it at an angle to free the bottom from the track.

2. Inspect the Rollers With the screen removed, examine the rollers and track. If the roller is adjustable, try to tighten or realign it before deciding to replace it. If damage is present, proceed to the next step.

3. Remove Old Rollers Depending on the design, the rollers may be held in place by screws or clips. Use your screwdriver to remove the old rollers carefully. Take note of how they were installed for easier reassembly.

4. Install New Rollers Position the new rollers in the same orientation as the old ones. Ensure they fit snugly and are secure. If your rollers have adjustable features, set them according to your preference.

5. Clean the Track Before reinstalling the screen, clean the track to eliminate dirt and debris that may impede smooth movement. Apply lubricant if necessary.

6. Reinstall the Screen Carefully place the screen back into the frame, ensuring that the rollers are seated properly in the track. Test the screen’s movement to confirm that it operates smoothly.

7. Final Adjustments If the screen is misaligned or still difficult to operate, check the roller adjustment settings and make necessary tweaks.

Maintenance Tips

Once you’ve replaced your sliding screen rollers, regular maintenance can help prolong their lifespan. Clean the track regularly, inspect the rollers periodically, and lubricate as needed. Ensuring that the screen is not exposed to excessive force can also help maintain its integrity.

Conclusion

Replacing sliding screen rollers is a straightforward task that can significantly improve the functionality of your screen door or window. By following the steps outlined in this guide, homeowners can restore ease of movement to their sliding screens while keeping pests out. If you are unsure about any aspect of the replacement process, consulting with a professional can ensure the best results.

-

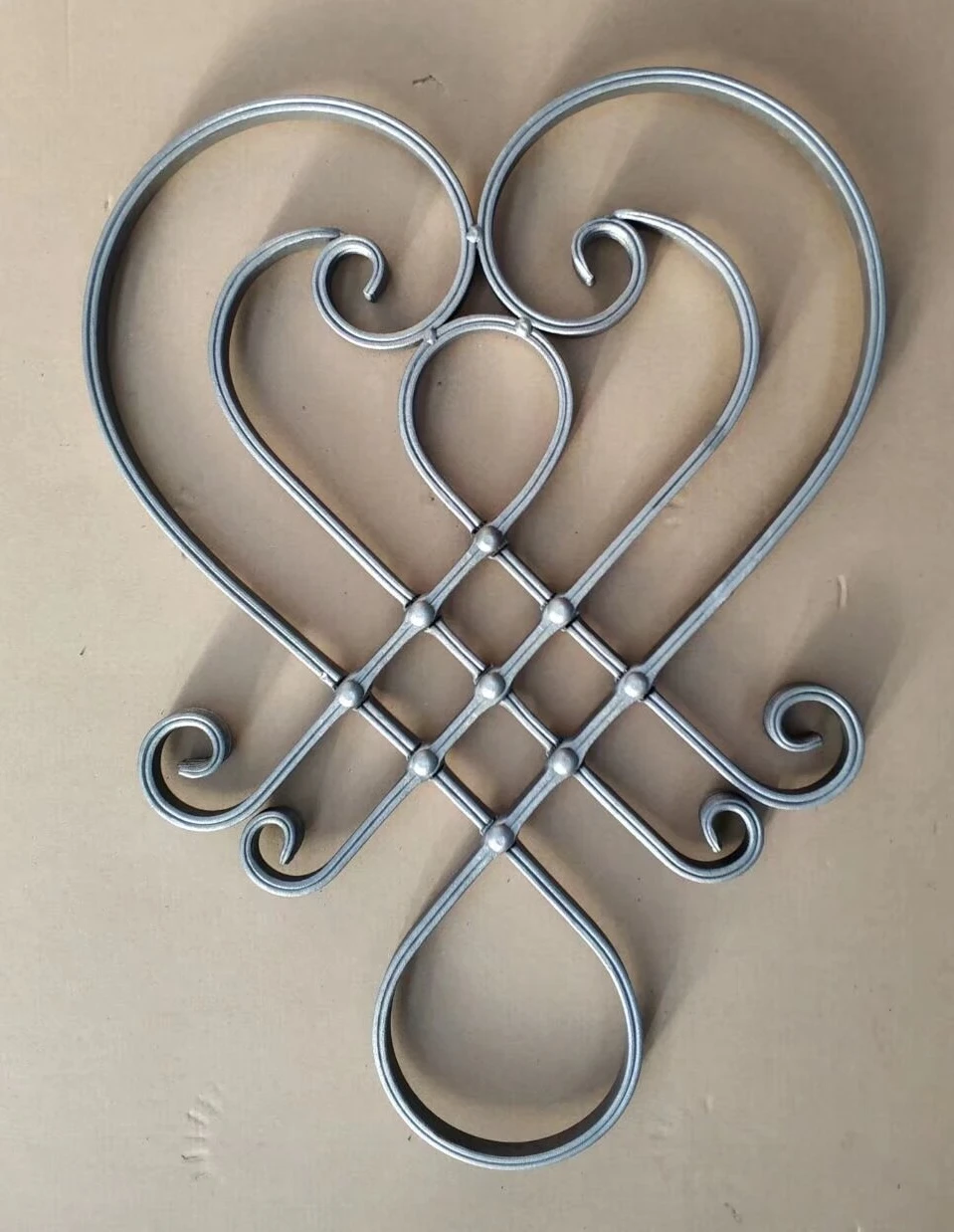

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters