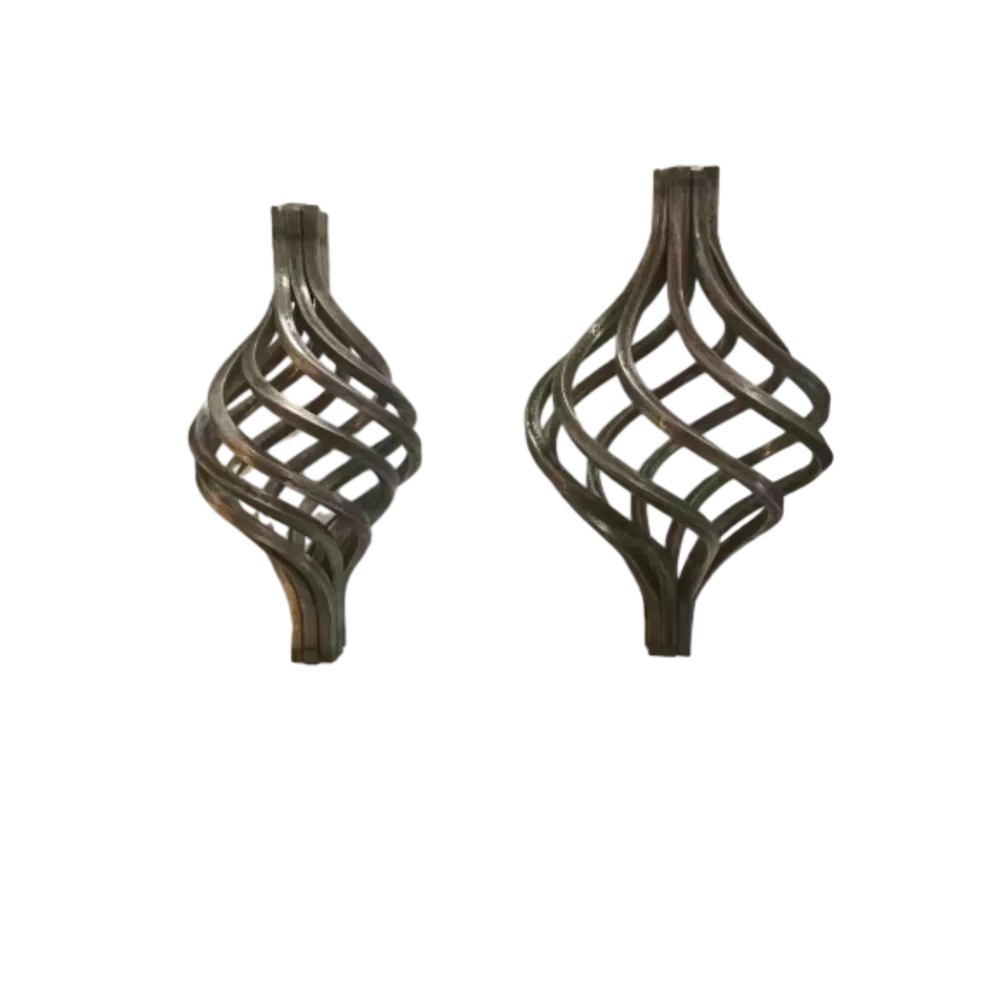

wrought iron parts

The Significance and Applications of Wrought Iron Parts

Wrought iron, a material known for its malleability and resistance to corrosion, has been used for centuries in various applications ranging from architecture to art. Characterized by its fibrous structure, wrought iron is produced through the controlled heating and working of iron, which removes impurities and enhances its unique properties. Today, wrought iron parts are prevalent in several industries due to their strength, durability, and aesthetic appeal. This article delves into the significance, production processes, applications, and advantages of wrought iron parts.

The Production of Wrought Iron

The manufacturing process of wrought iron involves heating the iron to a temperature where it becomes pliable but not molten, allowing it to be shaped through forging or pressing. Traditionally, wrought iron was produced in small quantities in a bloomery, where it was heated in a charcoal fire. Modern techniques involve more advanced methods, such as the puddling process, where molten iron is oxidized to remove carbon content, resulting in the desired wrought iron quality.

Wrought iron can also be produced using the slag refining technique, which yields a high-quality product by removing impurities and inclusions. The resulting material is highly workable, making it suitable for creating a wide array of parts and structures. This process not only improves the physical properties of the material but also preserves its distinctive fibrous texture, which is often considered a hallmark of quality wrought iron.

Applications of Wrought Iron Parts

Due to its favorable properties, wrought iron is commonly used in several applications, including

1. Architectural Components Wrought iron is a popular choice for architectural elements such as railings, gates, balconies, and decorative features. Its strength and beauty allow for intricate designs that enhance the aesthetic appeal of buildings. Historic structures often showcase wrought iron parts, reflecting the craftsmanship of past eras.

2. Furniture Furniture designers frequently incorporate wrought iron in pieces such as tables, chairs, and beds. The combination of durability and versatility allows for creative designs that can complement a variety of interior styles, from rustic to modern.

3. Artistic Endeavors Artists utilize wrought iron in sculptures and installations, taking advantage of its malleability to create detailed and expressive forms. The ability to maintain a finish through treatments or paints allows for further customization and artistic expression.

wrought iron parts

4. Industrial Applications In addition to artistic and architectural uses, wrought iron parts are applied in various industrial settings, including machinery and tools. Its resistance to deformation under stress makes it ideal for components that undergo heavy use.

5. Fencing and Security The durability and inherent strength of wrought iron make it an essential material for fencing and security systems. Wrought iron fences offer not only protection but also a visually appealing boundary solution for properties.

Advantages of Wrought Iron Parts

Several advantages contribute to the ongoing relevance of wrought iron in modern applications

1. Durability Wrought iron parts exhibit exceptional strength and resistance to wear, making them suitable for both indoor and outdoor use. They withstand harsh weather conditions and do not corrode easily, requiring minimal maintenance.

2. Malleability The unique properties of wrought iron allow it to be easily shaped into intricate designs, making it ideal for artistic and decorative applications.

3. Aesthetic Appeal The natural finish and craftsmanship associated with wrought iron parts provide an elegant touch to any project, whether it be a building, piece of furniture, or an art installation.

4. Recyclability As a metal, wrought iron is recyclable, contributing to sustainability efforts in construction and manufacturing industries.

Conclusion

In summary, wrought iron parts play a significant role in various sectors, from architecture to industrial applications. Their unique properties, aesthetic versatility, and durability make them a timeless material choice. As industries continue to evolve, the demand for wrought iron parts remains strong, affirming its place in both functional and artistic realms. Whether adorning a historic building or serving as the foundation for intricate furniture, wrought iron's legacy endures, celebrating craftsmanship and quality through the ages.

-

Window Lock Handle for Security UpgradesNewsJun.20,2025

-

Proper Lubrication Techniques for Sliding Gate WheelsNewsJun.20,2025

-

Ornamental Iron Castings for Interior DesignNewsJun.20,2025

-

Creative Ways to Decorate Around a Cast Iron FireplaceNewsJun.20,2025

-

Cast Iron Pipe and Fitting for Plumbing SystemsNewsJun.20,2025

-

Cast Iron Panel Casting for Architectural ElementsNewsJun.20,2025