Cast Iron Power Plants and Their Role in Energy Generation Systems

Cast Iron Foundries A Historical and Technological Overview

Cast iron has played a vital role in the development of various industries, serving as a fundamental material in construction, machinery, and art. Central to the production of cast iron are the foundries that specialize in its manufacturing. These establishments have a rich history, characterized by advancements in technology and shifts in the economic landscape.

The genesis of cast iron can be traced back to ancient China, with early artifacts dating as far back as the 5th century BC. However, it wasn’t until the 18th century, during the Industrial Revolution in Europe, that the technology for producing cast iron flourished. Foundries began to emerge, exploiting the plentiful resources of iron ore and coal. The rise of mechanization allowed for more efficient and larger-scale production processes, laying the groundwork for modern foundries.

Cast Iron Foundries A Historical and Technological Overview

In recent years, advancements in technology have revolutionized the operations of foundries. Modern techniques such as computer-aided design (CAD) and 3D printing have transformed the mold-making process. This allows for greater precision and flexibility, enabling foundries to produce intricate designs with minimal waste. Furthermore, the adoption of automation and robotics in the casting process enhances efficiency and safety, reducing the risk of workplace accidents.

centrales de hierro fundido

Environmental concerns have increasingly influenced the foundry industry, prompting the implementation of sustainable practices. Foundries have begun to adopt recycling methods, utilizing scrap metal in the production of new cast iron products. This not only helps in conserving natural resources but also significantly reduces energy consumption and greenhouse gas emissions. Additionally, regulations and technologies aimed at minimizing emissions from foundries have become commonplace, pushing the industry towards greener practices.

The applications of cast iron are vast and varied. From construction materials like manhole covers and pipes to intricate decorative pieces in architecture, its versatility is unmatched. Additionally, cast iron plays a crucial role in the automotive industry, where it’s used in engine blocks, brake components, and other critical parts due to its excellent wear resistance and thermal properties.

Despite the myriad of benefits cast iron offers, the foundry industry faces challenges, including competition from alternative materials and economic fluctuations. The rise of composite materials and lighter alloys has led to a decline in some traditional applications of cast iron. However, the qualities that make cast iron unique cannot be easily replicated, ensuring that it still holds a significant place in numerous sectors.

In conclusion, cast iron foundries stand at the intersection of tradition and innovation. While they are steeped in a rich historical legacy, they continue to evolve, embracing new technologies and sustainable practices. As industries advance and the demand for durable, reliable materials persists, cast iron is likely to remain a cornerstone of manufacturing for years to come. The fusion of ancient methods with modern technology ensures that cast iron foundries will continue to play a crucial role in shaping our built environment and technological future.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

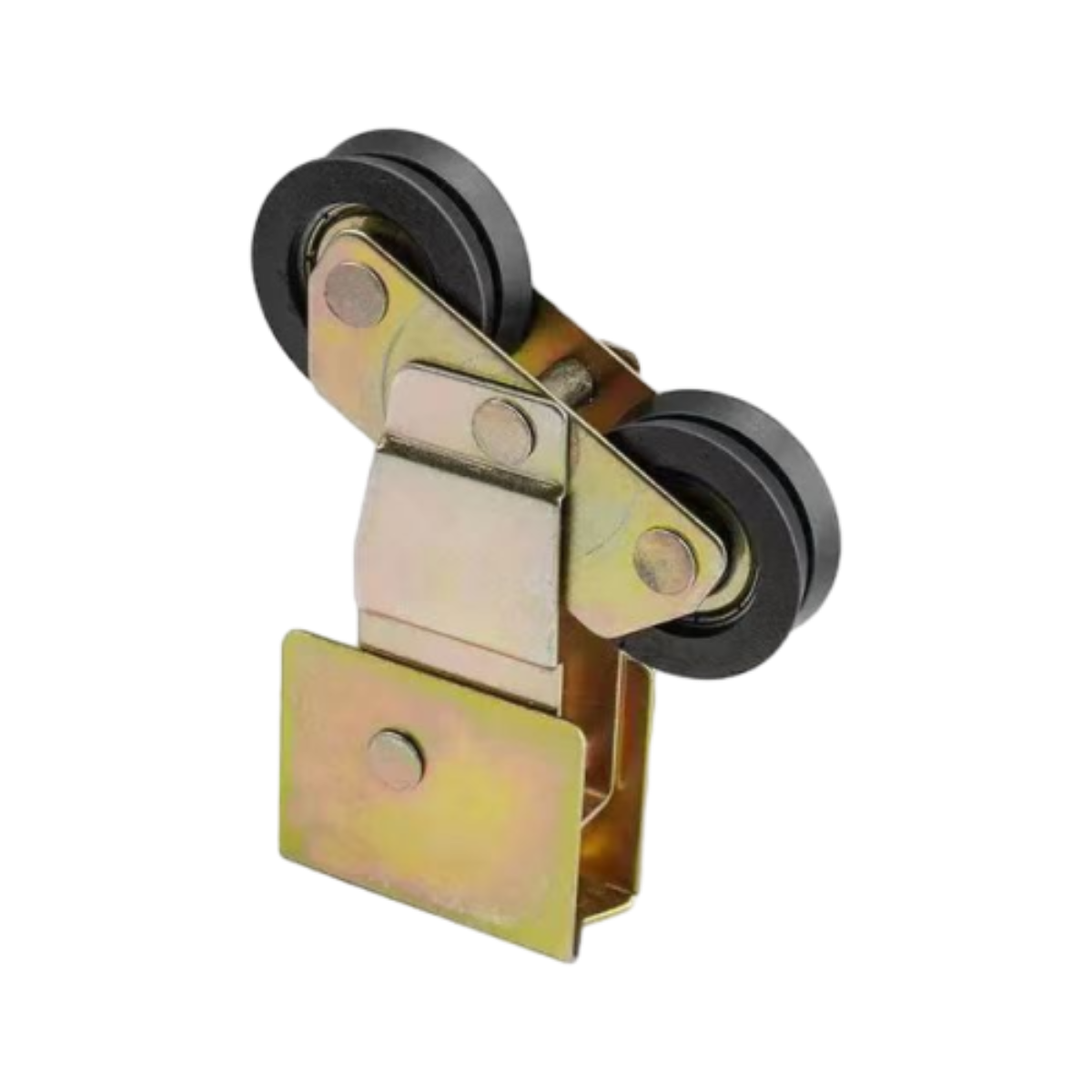

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters