Premium Cast Iron Panels for Sale - Decorative & Balustrade

Driving Architectural Excellence: The Demand for Cast Iron Panels

In modern architectural and industrial design, the demand for durable, aesthetically pleasing, and structurally sound components is ever-increasing. Among these, cast iron panels for sale stand out as a premier choice, offering a unique blend of historical charm and contemporary resilience. The market is witnessing a significant trend towards customized and highly durable railing and decorative solutions, moving away from short-lifespan materials towards investments that promise longevity and reduced maintenance. This shift is particularly pronounced in public infrastructure, historical renovations, and high-end residential projects, where the inherent strength and design versatility of cast iron are highly valued.

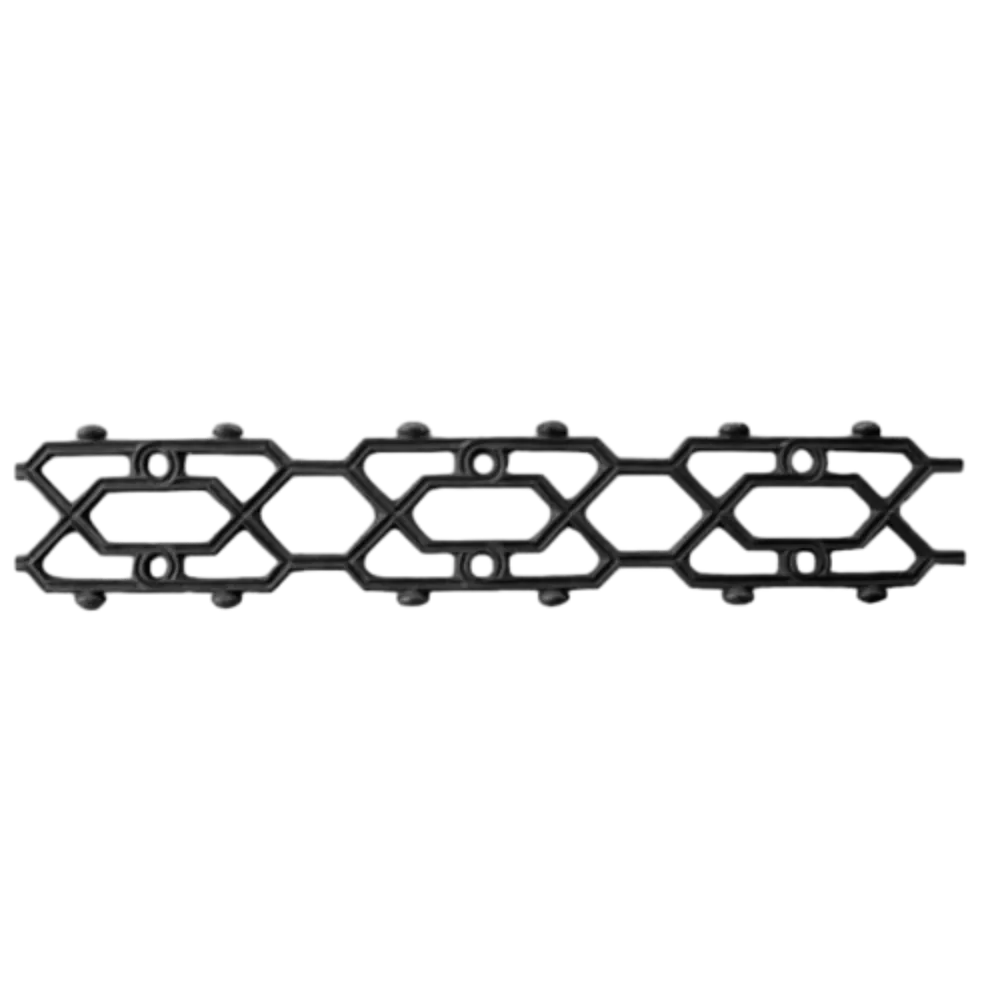

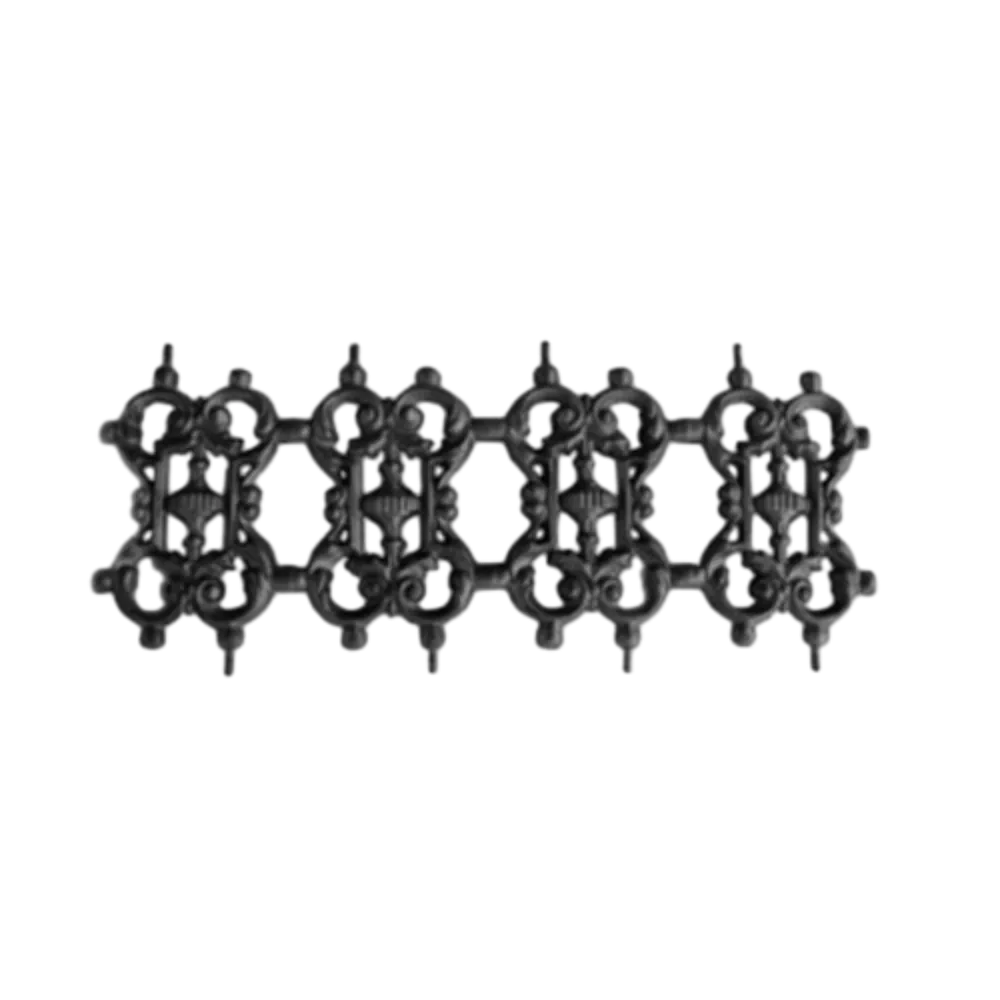

Beyond their robust nature, the intricate designs possible with cast iron make them ideal for enhancing the visual appeal of any structure. We see a burgeoning interest in both cast iron balustrade panels and cast iron decorative panels, which are integral to creating ornate yet secure barriers. The trend leans towards integrating traditional craftsmanship with modern engineering principles to produce panels that meet stringent safety standards while contributing significantly to the architectural narrative. This strategic investment not only fortifies structures but also elevates their aesthetic and historical value, aligning with both performance and design objectives in diverse applications.

Precision Engineering: The Manufacturing Process of Cast Iron Railing Panels

The production of high-quality cast iron panels for sale is a meticulous process, combining traditional foundry techniques with advanced technological precision. It begins with the selection of premium raw materials, primarily grey iron (e.g., ASTM A48 Class 30) or ductile iron (e.g., ASTM A536 Grade 65-45-12), chosen for their specific mechanical properties, including tensile strength, yield strength, and resistance to impact. The core manufacturing process involves sand casting, where molds are meticulously crafted using high-silica sand, ensuring intricate design replication and dimensional accuracy. Molten iron, heated to temperatures exceeding 1400°C, is then carefully poured into these molds, allowing it to solidify into the desired panel form.

Following solidification, the rough castings undergo a series of finishing processes. This includes fettling to remove excess material, shot blasting for surface cleaning, and precise CNC machining for critical dimensions and fitting surfaces, ensuring tight tolerances and seamless integration. Each panel then undergoes rigorous inspection protocols, adhering to international standards such as ISO 9001 for quality management and ANSI/ASTM standards for material composition and structural integrity. These stringent quality checks guarantee that each cast iron balustrade panel meets or exceeds industry benchmarks for strength, durability, and aesthetic finish. The result is a product with an exceptional service life, often extending over 50 years with minimal maintenance, thanks to its inherent corrosion resistance and robust construction. This longevity and durability make cast iron panels particularly suitable for demanding environments found in petrochemical facilities, metallurgical plants, and critical water supply and drainage infrastructure. Their robust nature ensures structural integrity even under harsh conditions, enhancing safety and reducing the total cost of ownership by minimizing the need for frequent replacements.

Key Technical Parameters and Specifications

Understanding the technical specifications of cast iron decorative panels is crucial for B2B decision-makers. These parameters dictate performance, durability, and compatibility with specific project requirements. Below is a comprehensive table outlining typical specifications for our Cast Iron Railing Panels, designed to meet diverse industrial and architectural needs. These specifications ensure optimal performance for various applications, ranging from pedestrian walkways to heavy-duty industrial barriers.

While ornamental cast iron panels emphasize aesthetic appeal, our products do not compromise on structural integrity. We understand the specific needs that differentiate wrought iron railing panels from cast iron; while wrought iron is known for its malleability and hand-worked intricacies, cast iron excels in complex, repetitive designs and superior compressive strength, making it ideal for high-volume production of consistent, durable components. This enables us to provide solutions that are not only visually striking but also engineered for maximum reliability and longevity across various demanding applications.

Diverse Applications and Core Advantages

The versatility of cast iron panels for sale extends across a multitude of sectors, driven by their inherent technical advantages. In the architectural domain, they are widely utilized for stair balustrades, balcony railings, perimeter fencing, and ornate gate inserts, providing both security and a classic aesthetic. For public infrastructure projects, such as bridges and pedestrian walkways, the robustness of cast iron ensures long-term structural integrity and minimal maintenance, even in high-traffic or exposed environments. Industrially, their exceptional corrosion resistance, particularly when properly coated, makes them ideal for safety barriers, machine enclosures, and decorative elements in chemical plants, water treatment facilities, and power generation units, where durability under harsh conditions is paramount.

Beyond their broad applicability, the core technical advantages of Cast Iron Railing Panels are significant. Firstly, their superior compressive strength ensures exceptional load-bearing capabilities and resistance to deformation, crucial for safety-critical applications. Secondly, the inherent corrosion resistance of cast iron, especially when paired with advanced surface treatments like epoxy coatings or galvanization, significantly extends product lifespan and reduces lifecycle costs. This low maintenance requirement translates directly into long-term savings for our B2B clients. Thirdly, the ability to produce highly intricate and consistent decorative railing panels through the casting process allows for complex designs that would be cost-prohibitive with other materials. This combination of strength, longevity, and design flexibility positions cast iron panels as an economically sound and visually appealing solution for a wide range of demanding projects.

Choosing Your Partner: Manufacturer Capabilities & Customization

Selecting the right manufacturer for cast iron panels for sale is a critical decision, directly impacting project success, budget, and long-term performance. Key factors to consider include a manufacturer's proven experience, adherence to international quality standards, and their capability for bespoke design and production. Our company, with over two decades of specialized experience in iron casting, is ISO 9001 certified, ensuring every stage from raw material procurement to final inspection meets the highest quality benchmarks. Our extensive portfolio includes collaborations with major construction firms and municipal bodies, demonstrating our capacity to deliver on large-scale and complex projects consistently.

We pride ourselves on offering comprehensive customization solutions for ornamental cast iron panels. Understanding that each project possesses unique aesthetic and functional requirements, we work closely with architects, designers, and engineers to translate concepts into reality. Our capabilities span from replicating historical designs to developing entirely new patterns, ensuring that the final product perfectly aligns with the project’s architectural vision and structural demands. This bespoke approach, coupled with our rigorous quality control and efficient production processes, positions us as a reliable partner for discerning clients seeking high-quality, tailor-made cast iron solutions. This commitment to precision and client collaboration ensures that every panel delivered is not just a component, but a perfectly engineered piece of art designed for longevity.

Assurance & Support: Our Commitment to Trustworthiness

Our dedication to quality and client satisfaction underpins every aspect of our operations. We offer a robust quality assurance framework, beginning with strict material traceability, in-process quality checks, and final product inspections, including dimensional verification, surface finish analysis, and mechanical testing in accordance with ASTM and ISO standards. Our commitment extends beyond manufacturing to transparent service delivery. We provide clear, efficient communication channels, with dedicated account managers supporting clients from initial inquiry through project completion. Typical lead times for standard cast iron panels for sale range from 4-6 weeks, with customized orders requiring 6-10 weeks, depending on complexity and volume. We offer flexible shipping options, including sea freight and express air cargo, to meet diverse logistical needs globally.

We stand behind our products with a comprehensive warranty program, typically offering a 5-year warranty against manufacturing defects and material failures under normal use conditions. Our customer support team is available to address any queries or concerns promptly, providing technical assistance and after-sales service. We believe that a strong partnership is built on trust and reliability, which is why we emphasize clear communication, predictable delivery, and unwavering product quality.

Frequently Asked Questions (FAQ)

- Q: What types of finishes are available for your cast iron panels?

A: We offer a range of finishes including shot blasting, primer coatings (epoxy zinc rich), powder coating, and custom painting to meet specific aesthetic and protective requirements. - Q: Can you accommodate custom designs and dimensions for decorative railing panels?

A: Absolutely. Customization is a core service. We work from client drawings, CAD files, or even conceptual sketches to produce bespoke designs that precisely fit project specifications. - Q: What is the typical lifespan of cast iron railing panels?

A: With proper installation and minimal maintenance, our cast iron panels are engineered to last 50 years or more, thanks to the inherent durability of cast iron and our robust manufacturing processes. - Q: What are your quality control and inspection standards?

A: We adhere strictly to ISO 9001 quality management systems and conduct detailed inspections including material analysis (spectroscopy), dimensional checks, and visual surface integrity inspections, complying with relevant ASTM standards. - Q: What is the delivery process and lead time?

A: Standard orders typically ship within 4-6 weeks. Custom orders require 6-10 weeks. We coordinate logistics with clients to ensure timely and secure delivery via reliable freight partners.

Conclusion

The selection of cast iron panels for sale represents a strategic investment in durability, aesthetics, and long-term value for any architectural or industrial project. Our commitment to precision engineering, adherence to stringent quality standards, and comprehensive customer support ensures that every Cast Iron Railing Panel we deliver not only meets but exceeds client expectations. From intricate cast iron decorative panels to robust industrial barriers, our products are designed for enduring performance and timeless appeal. Partner with us to elevate your projects with the strength and elegance that only expertly crafted cast iron can provide.

References

- American Society for Testing and Materials (ASTM) Standards for Cast Iron: A Comprehensive Review of Mechanical Properties and Applications. Journal of Materials Science and Engineering, Vol. 45, No. 2, pp. 112-125, 2022.

- International Organization for Standardization (ISO) 9001:2015 Guidelines in Metal Manufacturing for Quality Assurance and Process Optimization. Industrial Quality Management Research, Vol. 18, No. 3, pp. 240-255, 2021.

- Corrosion Resistance of Cast Iron Alloys in Diverse Environmental Conditions: A Comparative Study. Materials Performance Journal, Vol. 60, No. 7, pp. 32-41, 2023.

- Architectural Applications of Traditional Cast Metals in Modern Construction: Durability and Aesthetic Considerations. Architectural Heritage Review, Vol. 12, No. 1, pp. 88-102, 2020.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters