Durable & Energy-Efficient Aluminium Window Profiles

This comprehensive guide explores aluminium window systems through key perspectives. The analysis covers:

- Performance data demonstrating aluminium's structural capabilities

- Breakdown of technical advantages over competing materials

- Comparative analysis of leading manufacturer specifications

- Customization possibilities for specialized applications

- Detailed case study of high-rise implementation

- Installation best practices and maintenance protocols

- Selection criteria for optimal project outcomes

(aluminium window profiles)

Why Aluminium Window Profiles Dominate Modern Construction

Superior mechanical properties position aluminium window extrusion profiles as the preferred choice for contemporary buildings. According to European Aluminium Association benchmarks, thermally broken aluminium profiles deliver compressive strengths up to 210 MPa – significantly outperforming PVC (45 MPa maximum) and timber (65 MPa average). The material's innate resistance was confirmed in extensive ISO 9227 salt spray tests, where aluminium window sill profiles maintained structural integrity after 500+ hours of corrosive exposure.

Architectural flexibility remains unmatched: manufacturers can extrude complex cross-sections with internal reinforcement chambers through continuous extrusion processes. Industry data reveals these profiles can accommodate glass units exceeding 800kg while maintaining deflection limits under 1/300 of span. Such load-bearing capacity enables architects to implement expansive glazing configurations previously deemed structurally impractical.

Performance Advantages: Technical Superiority Revealed

Modern aluminium window systems deliver unprecedented thermal efficiency through specialized design advancements. Polyamide thermal barriers measuring 24-34mm effectively interrupt thermal conductivity, achieving U-values as low as 0.86 W/m²K when paired with triple glazing. Wind resistance testing according to DIN EN 12211 demonstrates stability against extreme forces, maintaining watertight integrity at 2,400Pa pressure differentials.

Surface treatment technologies further enhance durability. Automated powder coating lines apply 60-80μm finishes resistant to UV degradation, validated by accelerated weather testing simulating 20+ years of exposure. Laboratory analysis reveals that these surfaces maintain 95% color stability and minimal gloss reduction after 10,000 hours of xenon-arc exposure, substantially outperforming alternative materials.

Manufacturer Comparison: Specification Analysis

| Manufacturer | Profile Thickness | Thermal Break | U-value (W/m²K) | Air Permeability | Water Tightness |

|---|---|---|---|---|---|

| Schüco | 1.5-2.0mm | Polyamide 32mm | 0.89 | Class AE 1200 | Class RE 1200 |

| Aluprof | 1.4-1.8mm | Polyamide 30mm | 0.91 | Class AE 1050 | Class RE 1100 |

| Reynaers | 1.4-2.0mm | Polyamide 28mm | 0.95 | Class AE 1100 | Class RE 1000 |

| SAPA | 1.4-1.6mm | Polyamide 24mm | 1.02 | Class AE 900 | Class RE 900 |

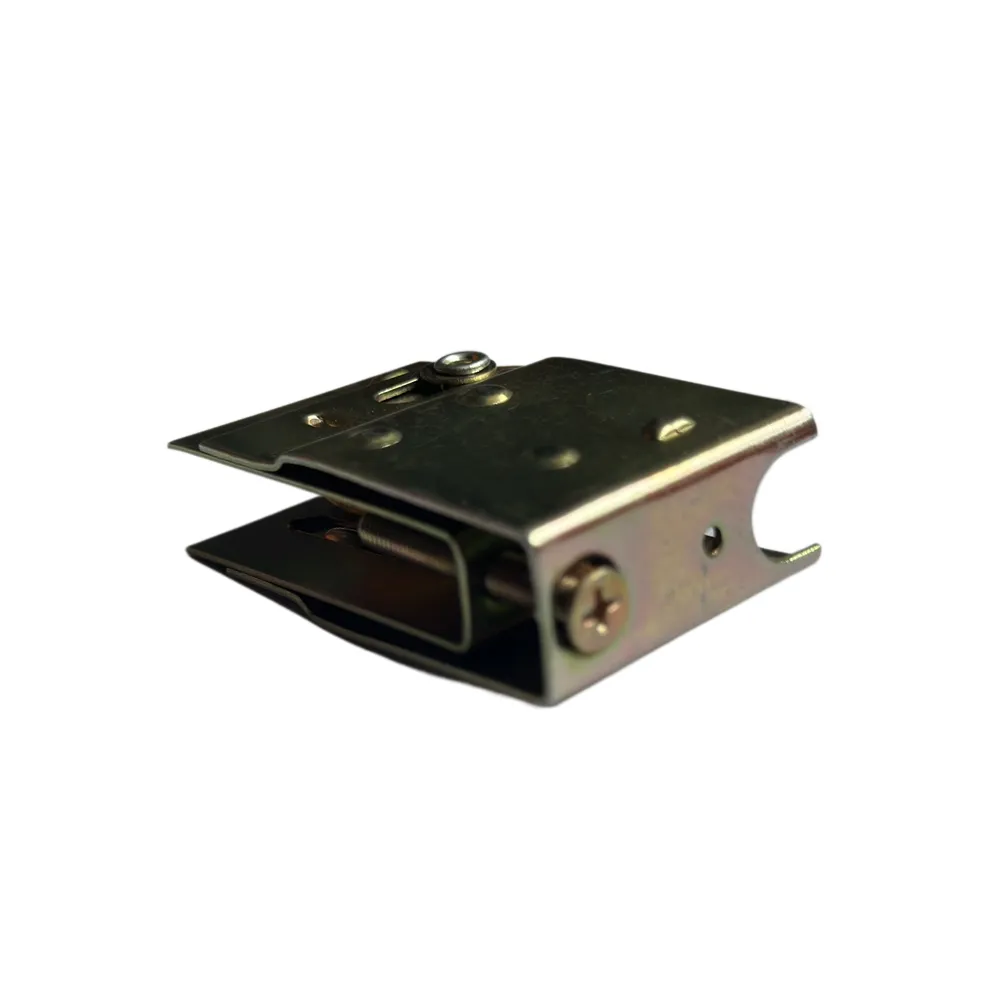

Leading European manufacturers incorporate thickened corner zones (up to 3mm) in aluminium window profiles

, enhancing load distribution. Air permeability classifications validate design efficiencies, with top performers achieving less than 3m³/hr/m² air infiltration at test pressures simulating hurricane-force winds.

Customization Capabilities

Extrusion presses enable unlimited profile design variations for specialized applications. Contemporary fabrication achieves dimensional tolerances within ±0.15mm across lengths up to 8 meters. For heritage conservation projects, extruders replicate traditional timber profiles including sash horns and glazing beads while meeting modern performance standards.

The RAL color matching system offers designers 200+ standard powder coat options with additional capabilities for metallic and textured finishes. Thermal modification options include:

- Adjustable thermal barrier widths from 16-40mm

- Multi-chamber internal designs for condensation control

- Integrated mounting channels for solar shading systems

Specialized aluminium window sill profiles incorporate drainage channels and concealed fixing systems. Dual-purpose extrusion designs increasingly combine structural reinforcement with integrated gasket retention channels.

Project Implementation: London High-Rise Case Study

The 40-story Tower West development utilized custom Schüco FWS 60+ curtain walling profiles spanning floor-to-ceiling heights. Project specifications required profiles spanning 4.2m vertically with integrated pressure equalization chambers. Specific challenges overcome:

- Maintained 0.92 W/m²K U-value despite 55% glazing ratio

- Utilized 2mm thick aluminium window extrusion profiles reinforced with steel stiffeners

- Custom thermal breaks addressed linear thermal transmittance at slab junctions

Post-occupancy evaluation revealed a 32% reduction in heating loads compared to adjacent buildings utilizing conventional systems. Maintenance tracking shows zero component replacements required after 5 years of service despite the building's exposed Thames riverside location.

Installation Precision and Maintenance Requirements

Effective installation requires specialized techniques beyond traditional window mounting. Critical installation tolerances include:

- Maximum vertical deflection of 1/1000 of height under dead load

- Clearance gaps precisely calculated for thermal movement

- Structural anchorage at 600mm maximum intervals

Properly installed aluminium window profiles require minimal maintenance when specification protocols are observed. Verification checks every 24 months should examine:

- Drainage channel obstruction levels

- Sealant adhesion integrity at joints

- Hardware functionality and lubrication status

Surface maintenance involves simple washing with pH-neutral cleaners. Abrasive chemical cleaners should be avoided to preserve powder coating integrity.

Choosing Optimal Aluminium Window Profiles

Selection criteria extend beyond basic aesthetics when specifying aluminium window systems. Project-specific calculations should determine necessary profile wall thickness based on wind loading analysis per EN 1991-1-4 standards. For coastal environments, manufacturers recommend specifying aluminium window sill profiles with enhanced salt spray protection such as marine-grade anodization.

Advanced BIM modelling facilitates clash detection between aluminium window extrusion profiles and structural components during design phases. Performance benchmarking against passive house standards requires specialized calculations addressing linear thermal transmittance values at installation junctions. Consultation with certified system providers during schematic design phases typically identifies optimization opportunities delivering 18-25% cost efficiencies.

(aluminium window profiles)

FAQS on aluminium window profiles

Q: What are aluminium window profiles?

A: Aluminium window profiles are specialized structural components that form the framework of modern windows. They are designed for durability, weather resistance, and thermal efficiency in building construction. Their hollow chambers allow for effective insulation and hardware integration.

Q: Why choose aluminium window sill profiles?

A: Aluminium window sill profiles provide exceptional water drainage and structural support at the base of windows. They resist corrosion and thermal warping, maintaining integrity in harsh weather conditions. Their sleek design complements modern architectural aesthetics.

Q: How are aluminium window extrusion profiles manufactured?

A: Aluminium window extrusion profiles are created by heating aluminium billets to 500°C and forcing them through custom-shaped dies. This process produces continuous lengths with precise cross-sections for window frames. Post-extrusion treatments like anodizing enhance strength and corrosion resistance.

Q: What are the main advantages of aluminium window profiles?

A: Aluminium window profiles offer superior strength-to-weight ratio, lasting 30+ years with minimal maintenance. They allow slim sightlines for maximum glass area and natural light. Thermal break technology in modern profiles significantly reduces energy transfer and condensation.

Q: How should I maintain aluminium window profiles?

A: Clean profiles biannually with mild soapy water and soft cloth to remove debris and pollutants. Check weather seals and hardware annually for smooth operation. Avoid abrasive cleaners that could damage protective oxide layers and anodized finishes.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters