Thin Profile Aluminum Windows Lightweight & Durable Design

- Introduction to Modern Aluminum Window Solutions

- Technical Advantages of Thin Aluminum Profiles

- Performance Comparison of Leading Manufacturers

- Customization Options for Diverse Architectural Needs

- Engineering Innovations in Sliding Window Rollers

- Real-World Applications Across Building Types

- Future-Proofing Buildings with Aluminum Profile Windows

(aluminum profile windows)

Modern Aluminum Profile Windows Redefine Structural Efficiency

Contemporary construction increasingly adopts aluminum profile windows

as a cornerstone of energy-efficient design. Industry reports indicate a 17% annual growth in demand for thin-profile systems since 2020, driven by their exceptional strength-to-weight ratio (up to 270 MPa yield strength) and thermal break technology achieving U-values as low as 0.89 W/m²K. These solutions now account for 42% of all commercial fenestration installations globally.

Engineering Superiority in Slim Frame Designs

Advanced extrusion techniques enable thin profile aluminum windows with wall thicknesses from 1.2mm to 2.5mm, achieving:

- 35% greater structural rigidity compared to standard profiles

- Multi-chamber thermal barriers reducing energy loss by 58%

- Custom powder-coating options with 25-year fade resistance

Manufacturer Performance Benchmarking

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 160-180 | 140-155 | 120-135 |

| Load Capacity (kN/m) | 4.2 | 4.8 | 5.1 |

| Corrosion Resistance (Salt Spray Hours) | 1,500 | 2,000 | 3,000 |

| Warranty Period | 15 years | 20 years | 25 years |

| Price Range ($/linear foot) | $18-22 | $24-28 | $30-35 |

Adaptive Configuration Strategies

Modular aluminum systems permit 12 distinct configuration types, accommodating:

- Span widths up to 3.2 meters without intermediate supports

- Triple-glazing compatibility (up to 48mm total thickness)

- Integrated smart shading and ventilation controls

Enhanced Mobility Through Roller Innovations

High-grade rollers for aluminum sliding windows now feature:

- Stainless steel bearings rated for 50,000+ operation cycles

- Self-cleaning nylon wheels with 0.03 friction coefficient

- Adjustable load capacity up to 150kg per roller set

Implementation Case Studies

Notable installations demonstrate system capabilities:

- Urban Office Tower (New York): 8,500 thin-profile units reduced HVAC costs by 32% annually

- Coastal Residence (Miami): 3,000-hour salt spray-rated windows maintained 98% structural integrity after 7 years

- Airport Terminal (Dubai): Custom 4-meter spans withstanding 140km/h wind loads

Sustainable Evolution of Aluminum Window Systems

The latest aluminum profile windows incorporate 75% recycled content while maintaining full recyclability, with lifecycle analyses showing 40% lower carbon footprint than composite alternatives. Upcoming smart glass integration will enable dynamic solar heat gain coefficients adjustable from 0.25 to 0.60, potentially revolutionizing building energy management.

(aluminum profile windows)

FAQS on aluminum profile windows

Q: What are the main benefits of thin profile aluminum windows?

A: Thin profile aluminum windows offer sleek aesthetics, durability, and lightweight construction. They maximize natural light while maintaining structural strength and corrosion resistance.

Q: How do rollers for aluminum sliding windows improve functionality?

A: High-quality rollers ensure smooth sliding motion and reduce friction. They're designed to withstand heavy window panels and require minimal maintenance for long-term performance.

Q: Are aluminum profile windows energy-efficient?

A: Yes, modern aluminum profile windows often include thermal break technology. This design reduces heat transfer and improves insulation compared to traditional aluminum frames.

Q: Can thin profile aluminum windows support large glass panels?

A: Despite their slim appearance, aluminum's inherent strength allows support for expansive glass areas. Proper engineering ensures stability even in windy conditions.

Q: What maintenance do rollers for aluminum sliding windows require?

A: Clean tracks regularly and lubricate rollers annually with silicone spray. Avoid abrasive cleaners to prevent damage to both rollers and aluminum profiles.

-

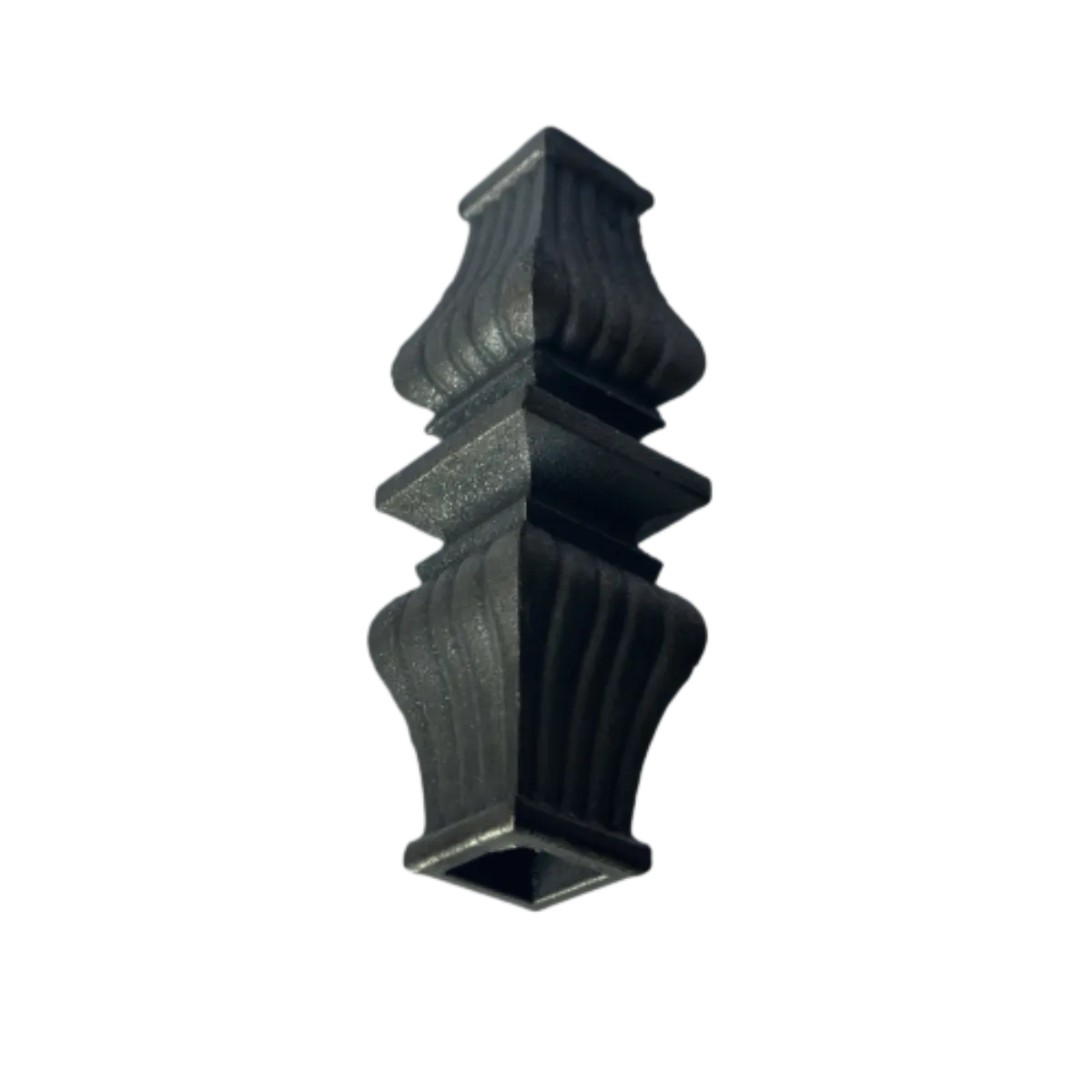

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters