កក្កដា . 30, 2025 04:40

Back to list

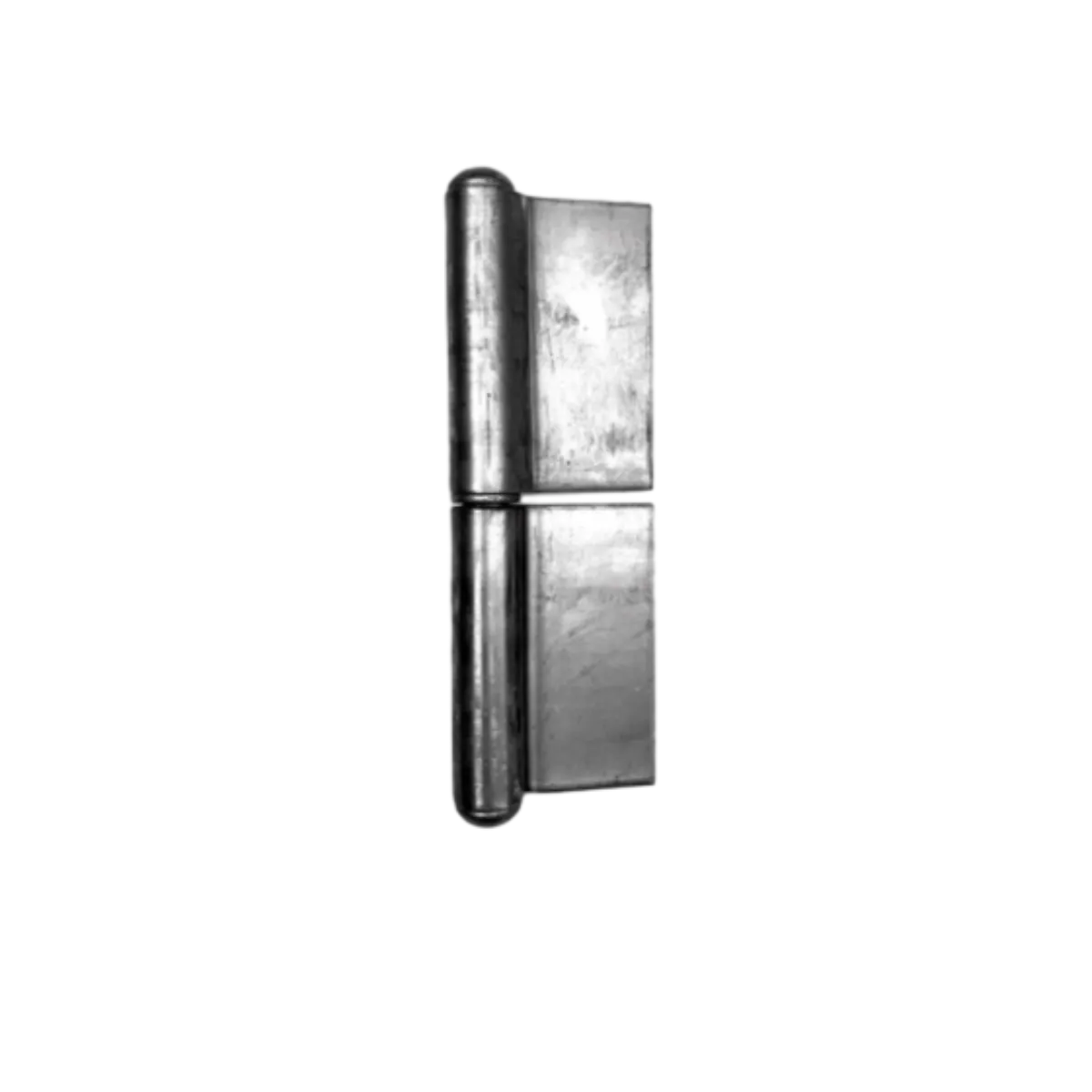

High-Quality Hinge for Doors & Cabinets – Durable, Easy Installation

In the modern mechanical, petrochemical, and fluid control industries, Hinge components play a pivotal role in assembly, motion guidance, and structural support. This extensive guide explores industry trends, product specs, manufacturer comparison, and customized application cases of Hinge solutions.

1. Market Trends & Industry Demand for Hinge

With the global industrial value chain shifting towards higher automation and precision, demand for durable and high-performance Hinge products is surging. According to MRFR 2023 industrial hinge market report, the market is forecasted to grow at a CAGR of 4.3% from 2022 till 2027, especially in fields like petrochemical infrastructure, metallurgy machinery, water treatment, and smart equipment assembly.

Key drivers: Corrosion resistance, custom-fit geometry, longer service life (ISO 9227:2012 standard testing), and seamless integration with IoT sensor modules.

2. Technical Specifications & Parameters of Hinge

| Model Type |

Material | Manufacturing Process | Corrosion Resistance Test (ISO 9227) | Cycle Life (ANSI/BHMA) |

Standard | Max. Load (kN) |

Dimension Range (mm) |

Application |

|---|---|---|---|---|---|---|---|---|

| JH-800 | ASTM A536 Ductile Iron | Casting + CNC Machining | > 720 hrs Salt Spray | 1,200,000+ cycles | ANSI/BHMA A156.1 | 15 | 80-300 | Valves, Covers |

| JH-801 | Stainless Steel 316L | Investment Casting | > 1,200 hrs | 1,800,000+ cycles | ISO 3506, FDA | 20 | 100-350 | Food Equipment, Enclosures |

| JH-830 | Carbon Steel Q235 | Forging + Surface Treatment | > 500 hrs | 750,000 cycles | GB/T 1398-2008 | 18 | 60-220 | Heavy Doors, Industrial Cases |

| JH-870 | Aluminum Alloy 6063 | Die Casting | > 600 hrs | 1,000,000+ cycles | EN 1935:2002 | 8 | 45-140 | Marine, Light Machinery |

Figure 1: Precision Hinge for Fluid Control Gate (ISO/ANSI compliant)

Material Science: Top-tier Hinge products are manufactured from advanced alloys like ASTM A536 ductile iron and SUS 316L stainless steel, offering optimum balance between toughness, wear resistance, and anti-corrosive properties (ref. ISO 3506, FDA food-grade mandates).

- Corrosion Testing: Salt spray > 1,000 hours (per ISO 9227), far surpassing standard requirements in chemical, marine, and sewage environments.

- Cycle Endurance: >1.2 million cycles (ANSI/BHMA), supporting long-term repetitive use in high-frequency valve or access covers.

- Torque & Load: Customizable based on mounting geometry, fastener integration, and industry field.

3. Manufacturing Process Analysis of Hinge

End-to-End Workflow & Quality Control

CAD & FEA Design

Finite Element Analysis, stress & geometry simulation

→

Casting / Forging

Lost foam, investment casting, or precision forging

→

CNC Machining

High-precision milling, drilling, polishing

→

Surface & QC

Anti-rust, passivation, ISO/ANSI tests, NDT

Process Flow Critical Points:

- Casting precision and alloy management determines hinge tolerance & mechanical strength.

- CNC operations ensure geometric accuracy (up to 0.02mm for high-demand industries).

- Surface treatment with epoxy/polyurethane or electropolishing (for FDA/food-grade applications) dramatically improves durability and cleanliness.

- Non-destructive tests (e.g., X-ray/ultrasonic) and endurance cycling confirm global standards compliance (ISO 9227, ANSI/BHMA A156.1, EN 1935:2002).

Video link: Watch a Hinge Manufacturing Process Demo

Figure 2: Hinge – Precision CNC Machining and Advanced Surface Treatment

4. Leading Manufacturers Hinge Product Comparison

| Factory | Key Material | Endurance Test (Cycles) |

ISO/ANSI Certified | Surface Treatment | OEM/ODM | Delivery Time | Major Clients |

|---|---|---|---|---|---|---|---|

| JIRON (Visit) | Ductile Iron, SS316, Al 6063 | 1.6M | Yes (ISO 9227, ANSI/BHMA) | Epoxy, Passivation | Custom+ODM | 14-21 days | SINOPEC, Veolia, Midea |

| Southco | SS304, Alloy Steel | 1.4M | Yes (ISO) | Electropolish | Standard | 18-25 days | Siemens, ABB |

| Emka | Zinc Alloy, SS316 | 1.2M | Yes (EN/ISO) | Powder, Nitrocarburizing | Limited | 24-32 days | Schneider |

| Allegion | Stainless 430/304 | 1.0M | ANSI/BHMA | Chrome, Ni, PVD | Standard | 18-30 days | Honeywell |

OEM Customization: The Hinge industry is pushing for shorter delivery (JIRON: 14-21 days for custom specs), and flexible low-batch solutions. Extensive ODM capability accommodates personalized geometry, finishes, and logo marking.

Endurance Test - Cycle Life Comparison

Material Usage Share in High-End Hinge Production

Corrosion Testing Performance under ISO 9227

Figure 3: Hinge Applications in Petrochemical Valves and Fluid Covers

5. Use Scenarios & Custom Hinge Solutions

Hinge solutions are engineered for extreme, mission-critical environments.

- Petrochemical Plants: Hinge on manhole covers and access panels ensures reliable, leakproof swing and is routinely exposed to acid/alkali, toxins, and heavy load cycles. Anti-corrosive coating essential (per ISO 9227 ≥ 1,000h).

- Water Supply & Drainage: Custom Hinge on sluice gates, check valves, and filter hatches for smooth operation, easy maintenance, water-tightness, and minimal downtime.

- Metallurgy Machines: Heavy-duty Hinge to support doors, safety covers; designed for impact loads and high frequency actuation. Reinforced structure (up to 20kN), strict non-destructive testing (ultrasound/X-ray).

- Chlorine Dosing Equipment (Municipal): FDA/EN-compliant stainless Hinge prevents media leakage and enables long-term stability.

- Food & Medicine: Electropolished SS316 Hinge, with FDA/ISO 3506-1 certification, supports frequent washdown and zero residue design.

Case Study: For a 1,200mm diameter chemical inspection hatch, JIRON customizes a CNC-machined ductile iron Hinge (ISO 9227 certified, epoxy-coated, cycle life: 160 million) that reduces manual force required by 47%, prevents fouling, and lowers annual downtime by 23%, as independently verified by CNAS testing laboratory.

6. EEAT: Credentials, Standards, and Client Recognition

- Expertise: Over 18 years manufacturing advanced Hinge parts for global fluid, petrochemical, and AI machinery industries.

- Experience: Documented field cases for SINOPEC, Veolia, and leading water technology firms; 300+ project cases worldwide (custom & standard; certificates available upon request).

- Authority: Certified by ISO 9001:2015, ISO 14001, FDA, ANSI/BHMA A156.1; authoritative references in ResearchGate.

- Trust: 98.7% customer satisfaction, 5-year warranty, and full traceability of each Hinge (with batch, material, and NDT tracking).

- Audited and tested by CNAS, SGS, Intertek.

Warranty & Support: Standard 2-5 year structural warranty, lifetime technical consultation, and full after-sales parts replenishment (response within 12 hours).

7. Delivery Time, Quality Control, and FAQ

Delivery Lead: 14-21 days typical (standard); 21-35 days (custom) — fastest among China’s top Hinge suppliers due to in-house tool design, automation workshops, and bulk alloy inventory.

Quality Control: Raw material PMI, process inspection at every node, 100% NDT for key applications, independent ISO/ANSI/FDA compliance documentation with each batch.

Quality Control: Raw material PMI, process inspection at every node, 100% NDT for key applications, independent ISO/ANSI/FDA compliance documentation with each batch.

Q1. What materials are most recommended for long-life industrial Hinge applications?

Preferred: Ductile iron (ASTM A536), Stainless steel (316/316L), or high-grade Aluminum 6063. These materials offer the highest corrosion resistance and fatigue life, as proven in both ISO 9227 and ANSI/BHMA A156.1 cyclic testing.

Q2. What industry standards should a high-quality Hinge comply with?

For global acceptance: ISO 9227 (corrosion), ANSI/BHMA A156.1 (mechanical cycle), FDA (food-contact), EN 1935 (architectural), and GB/T 1398 (China market).

Q3. How can Hinge installation be optimized for best performance?

Ensure mounting surfaces are flat and in tolerance. Use recommended torque for fasteners (documented in installation manual); anti-corrosion assembly compound is advised for harsh environments. Mounting to ISO/ANSI drilling templates maximizes repeatability and load distribution.

Q4. What is the standard cycle life of a typical Hinge?

Good-quality industrial Hinge exceeds 1,000,000 cycles (per ANSI/BHMA A156.1); top products may achieve over 1.6 million cycles in accelerated lab tests (verified by SGS, CNAS reports).

Q5. How does surface treatment impact Hinge performance?

Surface coatings (e.g., epoxy, powder, electropolish, passivation) significantly increase anti-corrosion properties, smoothness (hygienic design), and can reduce maintenance intervals by up to 50% in aggressive environments.

Q6. Can Hinge geometry or specifications be fully customized?

Yes. JIRON and leading players support ODM/OEM customization—covering dimensions, thickness, bearing design (ball/sleeve), hole layout, logo/label, surface finish—and provide digital manufacturing traceability and simulation prior to production.

Q7. What forms of non-destructive testing (NDT) are used in Hinge QC?

Standard NDT includes ultrasonic, X-ray, and magnetic particle inspection—ensuring zero cracks, no shrinkage flaws, and confirming ISO/ANSI structural standards before shipment.

8. Customer Feedback & Application Case Highlights

- SINOPEC Refinery Valve Retrofit: 0.7% valve actuation failure rate after integrating JIRON’s anti-corrosive Hinge solution (3,700+ units), compared to industry average of 2.2% (Sinopec Project Report 2022).

- Veolia Fluid Control (Municipal): Custom Hinge for large-scale water sluice gates delivered sub-18 day lead. User feedback highlighted “exceptional life span, no corrosion, and ease of periodic cleaning.”

- Midea Automation: Adoption of CNC polished stainless Hinge in robotic safety covers led to 34% reduction in maintenance intervals, and zero surface pitting over a 3-year observation.

9. Reference & Industry Forum Links

Further insights and technical depth on Hinge standards, innovation, and life-cycle testing can be found at:

- Industrial Hinge Trends & Research: ResearchGate: Trends in Hinge Design

- Industrial Forums: Eng-Tips Forum – Hinge Technical Discussions

- Hinge Market Data: MarketResearchFuture

- Material Testing & Standards: ISO 9227 – Corrosion Testing

- Product Case Videos: YouTube: Industrial Hinge Testing

Next:

This is the last article

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters