Understanding the Characteristics and Applications of Wrought Metal in Modern Manufacturing

Understanding Wrought Metal Characteristics and Applications

Wrought metal, a term often used in metallurgy, refers to metals that have been mechanically worked to shape and enhance their properties. This process can involve techniques such as forging, rolling, or extrusion, which change the metal's structure and improve its mechanical attributes. In this article, we explore the characteristics, advantages, and applications of wrought metal to understand its significance in various industries.

Characteristics of Wrought Metal

Wrought metals are distinguished by their superior mechanical properties, primarily due to the deformation processes they undergo. Unlike cast metals, which are shaped by pouring molten material into molds, wrought metals are shaped while solid, resulting in finer grain structures. This leads to several beneficial characteristics

1. Improved Strength Wrought metals typically exhibit greater tensile strength compared to their cast counterparts. The mechanical working process aligns the metal’s internal structure, improving its resistance to deformation and fracture.

2. Ductility and Malleability Wrought metals can be easily shaped and formed without breaking, allowing for versatile applications. This makes them a preferred choice for components that require precise dimensions and shapes.

3. Fatigue Resistance Due to their refined grain structure, wrought metals possess excellent resistance to fatigue. This is essential in applications where materials are subjected to cyclic loading.

4. Surface Finish Wrought metals often have a superior surface finish compared to cast metals, which can reduce the need for additional machining or finishing operations.

Common Types of Wrought Metals

what is wrought metal

Some common examples of wrought metals include aluminum, copper, steel, and titanium. Each type has its unique properties and applications. For instance, aluminum is lightweight and resistant to corrosion, making it ideal for aerospace applications. Steel, particularly wrought iron, is known for its hardness and durability, often used in construction and heavy machinery.

Advantages of Wrought Metals

The advantages of using wrought metals extend beyond their physical properties. They are often more reliable and predictable in terms of performance. Wrought metals are generally easier to work with during fabrication processes, which can reduce production costs and lead times. Additionally, the ability to create complex shapes and components increases design flexibility for engineers and manufacturers.

Applications of Wrought Metals

The applications of wrought metals span numerous industries, including

- Automotive Industry Wrought metals are widely used in vehicle frames, engine components, and various structural parts, where strength and weight reduction are critical. - Aerospace Sector The aerospace industry favors wrought metals like titanium and aluminum for their high strength-to-weight ratios, crucial in aircraft design for improving fuel efficiency and performance. - Construction Steel and wrought iron are essential materials in construction for beams, columns, and reinforcements, providing structural integrity to buildings and bridges.

- Manufacturing In manufacturing, wrought metals are often used for tools, dies, and components where precision and durability are paramount.

Conclusion

Wrought metals are vital materials in modern manufacturing and engineering, known for their distinct advantages over cast metals. Their strength, ductility, and versatile applications make them essential in various industries, from automotive to aerospace. As technology progresses, the ongoing development of wrought metal processes and alloys ensures that these materials will continue to play a crucial role in meeting the demands of advanced manufacturing and construction. Understanding the properties and applications of wrought metals not only highlights their importance but also encourages innovation in material science.

-

Why Choose Cast Iron for Your Next Project?NewsApr.27,2025

-

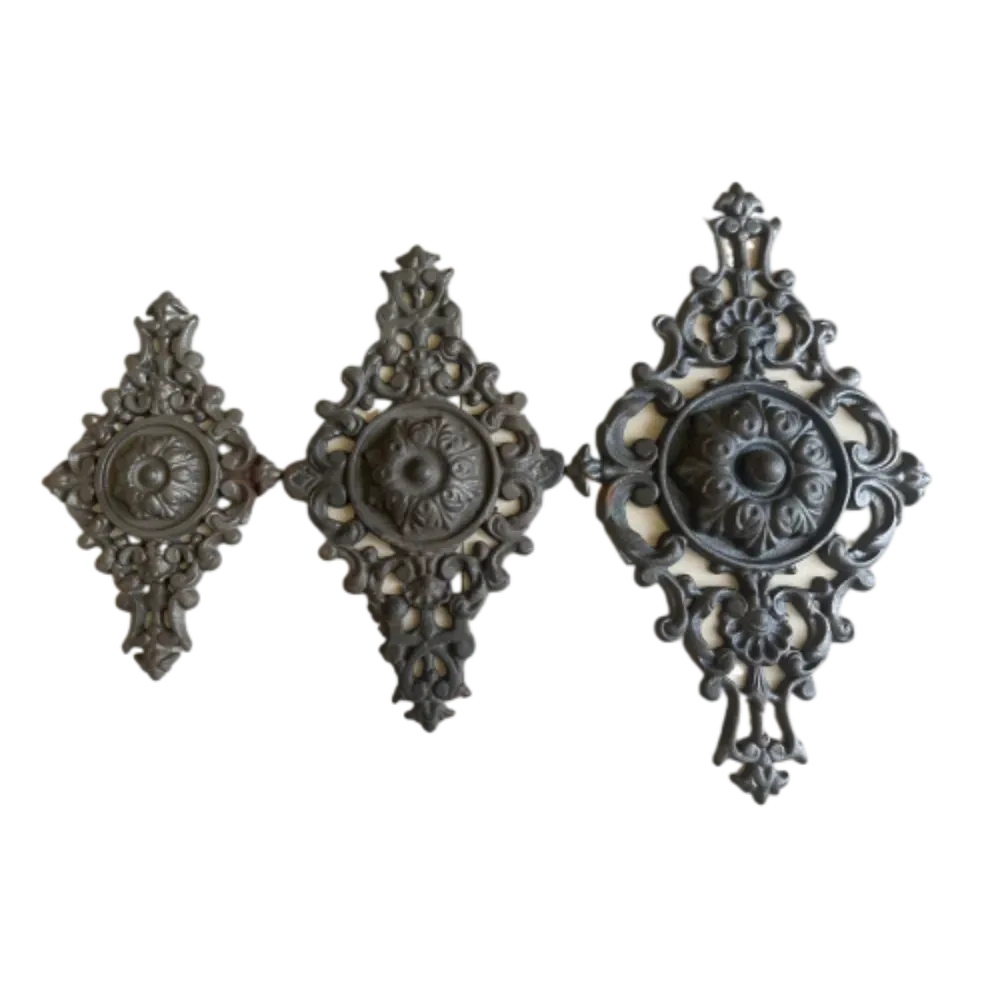

Timeless Charm of Cast Iron Decorative ElementsNewsApr.27,2025

-

Wholesale Cast Iron Products: A Growing Trend in Home and Garden DécorNewsApr.27,2025

-

The Advantages of Using Ornamental Cast Iron Parts in Your Design ProjectsNewsApr.27,2025

-

Why Ornamental Iron Castings Are Essential for Timeless DesignNewsApr.27,2025

-

The Elegance and Durability of Ornamental Cast Iron PanelsNewsApr.27,2025