aluminum window frame extrusions

Understanding Aluminum Window Frame Extrusions

Aluminum window frame extrusions are a popular choice in modern construction and architectural design

. Known for their durability, strength, and aesthetic appeal, these extrusions serve as a vital component in creating energy-efficient and visually pleasing window systems. In this article, we will explore the benefits, manufacturing process, and applications of aluminum window frame extrusions.One of the primary advantages of aluminum is its lightweight nature combined with significant strength. Unlike other materials such as wood or steel, aluminum offers a high strength-to-weight ratio, making it easier to handle and install. This property allows builders and architects to design larger windows without compromising structural integrity. Additionally, aluminum's resistance to corrosion ensures longevity, minimizing maintenance costs and the need for frequent replacements.

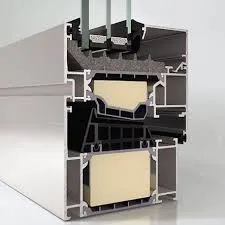

The manufacturing process for aluminum extrusions involves several stages. Initially, aluminum ingots are heated and then forced through a die to create the desired cross-sectional profile. This extrusion process can produce complex shapes specifically designed for window frames, allowing for increased customization. Once extruded, the frames undergo various treatments, including anodizing or painting, which enhances their appearance and provides added protection against the elements. This treatment not only improves aesthetics but also increases resistance to scratches, fading, and environmental exposure.

aluminum window frame extrusions

In terms of thermal performance, aluminum window frame extrusions can be enhanced with thermal breaks, which are materials inserted between the inner and outer portions of the frame. This innovation helps reduce heat transfer, making aluminum windows more energy-efficient. By minimizing thermal bridging, these windows contribute to lower energy costs, which is a crucial factor in today’s market, where sustainability and energy efficiency are highly valued.

Another essential aspect of aluminum windows is their design versatility. With the ability to be manufactured in a range of colors and finishes, aluminum frames can complement various architectural styles, from modern to traditional. They can be easily powder-coated or painted, allowing homeowners and builders to choose a finish that best suits their preferences. Moreover, aluminum frames can be designed to accommodate different glazing options, including double or triple-glazed units, further enhancing their energy efficiency and sound insulation capabilities.

In conclusion, aluminum window frame extrusions represent an innovative solution for contemporary building design. Their combination of strength, lightweight nature, and resistance to environmental challenges makes them an ideal choice for both residential and commercial applications. As energy efficiency becomes increasingly important, the ability of aluminum to integrate thermal breaks ensures that these frames meet modern standards. Whether in a sleek modern office or a cozy family home, aluminum window frames contribute significantly to aesthetic appeal and energy efficiency, making them a leading choice in the construction industry. As technology advances, we can expect to see further improvements in aluminum extrusion techniques, continuing to set a standard for quality and sustainability in window design.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters