Innovative Designs for Efficient Iron Casting Processes and Techniques

Iron Casting Designs An Overview

Iron casting is a manufacturing process that has been utilized for centuries to produce intricate and durable components for various industries. The versatility of iron casting has made it an essential technique in the production of items ranging from decorative art pieces to heavy machinery parts. The design of iron castings plays a critical role in optimizing functionality, aesthetics, and manufacturability, making it a vital consideration for engineers and designers alike.

Types of Iron Castings

There are several types of iron castings, each tailored to specific applications. The most common types include gray iron, ductile iron, white iron, and malleable iron. Gray iron, known for its excellent castability and wear resistance, is widely used for engine blocks, pipes, and machinery bases. Ductile iron, on the other hand, offers improved strength and ductility, making it suitable for automotive components and heavy-duty applications. White iron possesses high hardness, making it ideal for wear-resistant applications, while malleable iron is typically used for intricate parts that require flexibility.

Design Considerations

When designing an iron casting, several factors must be taken into account to ensure the final product meets performance and aesthetic requirements. The design process begins with defining the parameters of the casting, including dimensions, tolerances, and weight specifications. Engineers must also consider the physical properties of the iron alloy being used, as these will influence the part’s mechanical properties and performance under operational conditions.

One of the primary considerations in iron casting design is the gating and riser system. Gating refers to the channels through which molten iron flows into the mold, while risers are sections that hold extra molten material to compensate for shrinkage during cooling. A well-designed gating and riser system minimizes defects such as air entrapment and cold shuts, ensuring that the final casting is of high quality.

iron casting designs

Another important aspect is the wall thickness of the casting. Uniform wall thickness is crucial to achieve balanced cooling rates, which helps to prevent warping and defects. Designers often use computer-aided design (CAD) software to simulate the cooling process and identify potential issues before production begins.

Aesthetic Design

In addition to functional considerations, aesthetic design is an essential aspect of iron casting. Many products, particularly those used in architecture and art, require a visually appealing finish. Factors such as surface texture, color, and detailing can significantly impact the final product's appearance. Techniques like sand casting can create intricate patterns and textures, while finishing processes such as painting, powder coating, or polishing enhance the visual appeal of the cast iron.

Sustainability and Innovation

As industries evolve, the demand for sustainable practices in manufacturing has increased. Iron casting processes are becoming more environmentally friendly through the use of recycled materials and energy-efficient methods. Innovations in casting technology, such as 3D printing and advanced mold-making techniques, are also helping to reduce waste and improve efficiency in the production process.

Conclusion

Iron casting designs are integral to a wide range of applications, combining functionality with aesthetics to meet the needs of diverse industries. By considering factors such as material properties, casting techniques, and aesthetic elements, designers can create high-quality iron castings that are both durable and attractive. As technology continues to advance, the future of iron casting holds promise for even more efficient and sustainable practices, ensuring that this age-old technique remains relevant in modern manufacturing.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

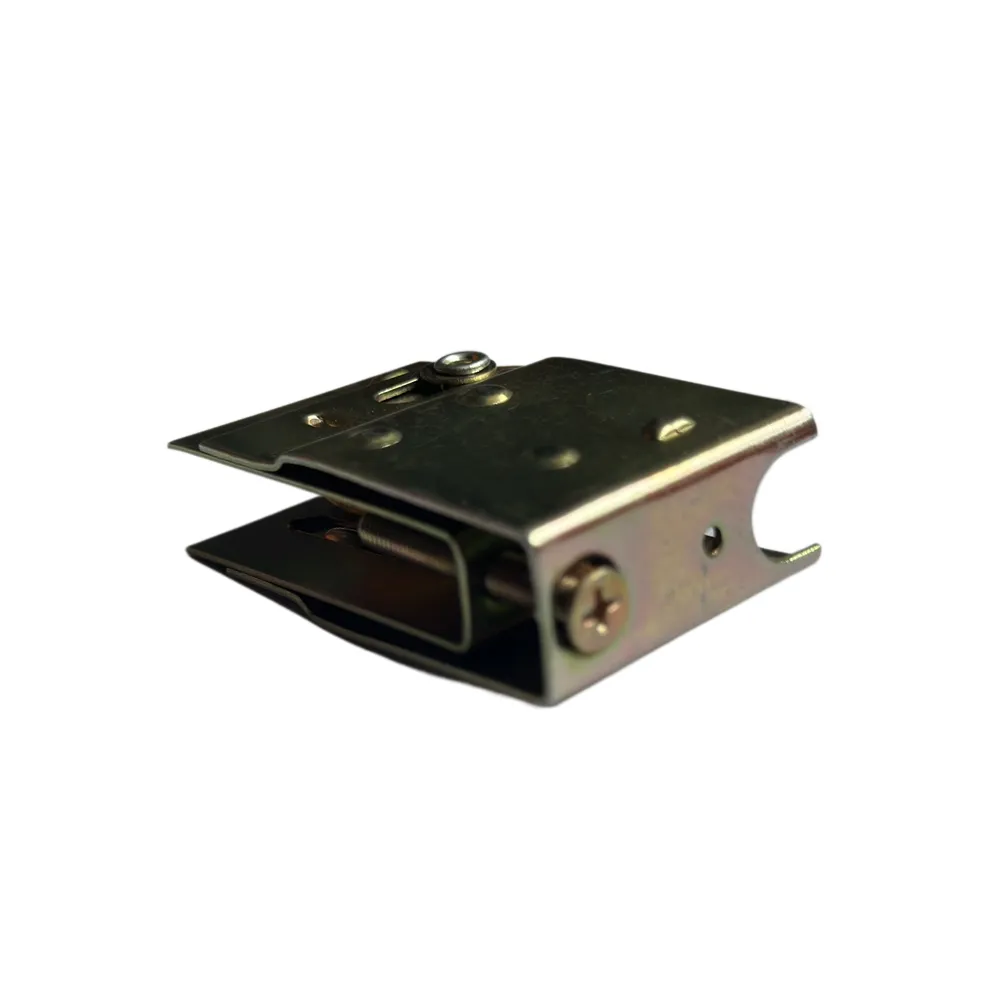

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters