The Process of Producing Wrought Iron Explained in Simple Terms

How Wrought Iron is Produced

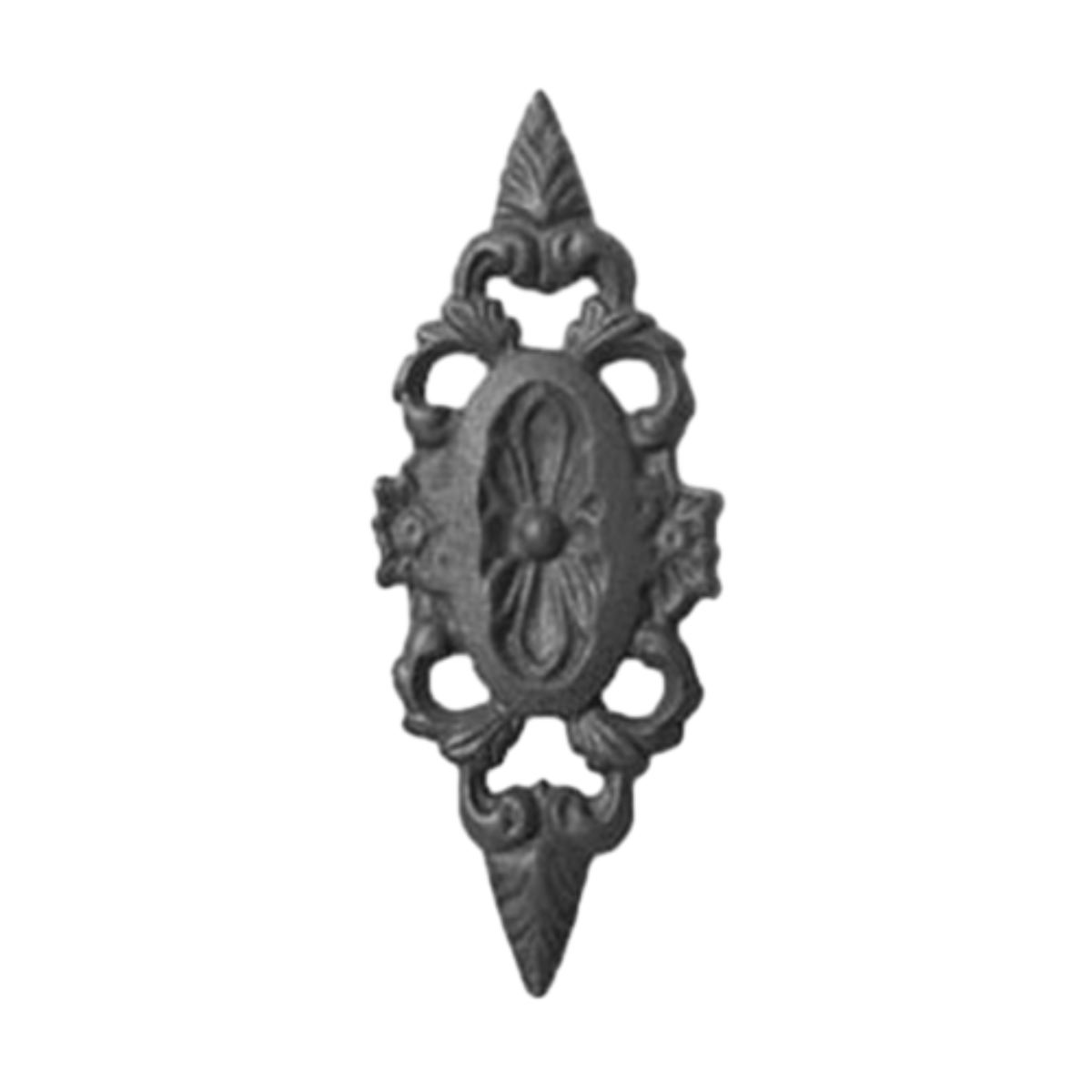

Wrought iron is a type of iron alloy that is known for its ductility, malleability, and resistance to corrosion. This versatile metal has been used for centuries in various applications, from decorative elements to structural components, and remains a popular choice among artisans and builders. The production of wrought iron is a fascinating process that combines traditional techniques with modern technology.

How Wrought Iron is Produced

After the initial smelting, the next step is to refine the iron by removing the slag and any remaining impurities. This refining process is crucial as it enhances the quality of the iron. Modern methods, including the use of a converter or induction furnace, allow for more precise control over the composition and properties of the final product. In traditional wrought iron production, the bloom is repeatedly heated and hammered to separate the iron from the slag. This technique not only purges unwanted materials but also aligns the iron's crystalline structure, resulting in a tough and malleable metal.

how is wrought iron produced

Once the iron has been sufficiently refined, it can be shaped into various forms through a process known as forging. Forging involves heating the metal to a workable temperature and then hammering or pressing it into the desired shape. This process can be performed by hand or using mechanical presses and hammers. The forging of wrought iron is often accompanied by techniques such as twisting, bending, and scrolling, which enhance its aesthetic appeal. The resulting products can range from tools and hardware to intricate decorative pieces found in gates, railings, and furniture.

It's important to note that wrought iron is distinct from cast iron. While cast iron is produced by pouring molten iron into molds and allows for complex shapes, wrought iron is crafted through mechanical manipulation of the metal, yielding a stronger and more flexible product. Because of this, wrought iron is favored in applications where durability and resistance to stress are paramount.

In conclusion, the production of wrought iron is a meticulous process that involves the combination of traditional and modern techniques. From the smelting of iron ore to the forging of delicate designs, the artistry and science behind wrought iron make it a unique material with a rich history. Its enduring strength and beauty continue to captivate those who work with it today, ensuring its place in both functional and decorative contexts.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters