ഫെബ്രു . 17, 2025 23:30

Back to list

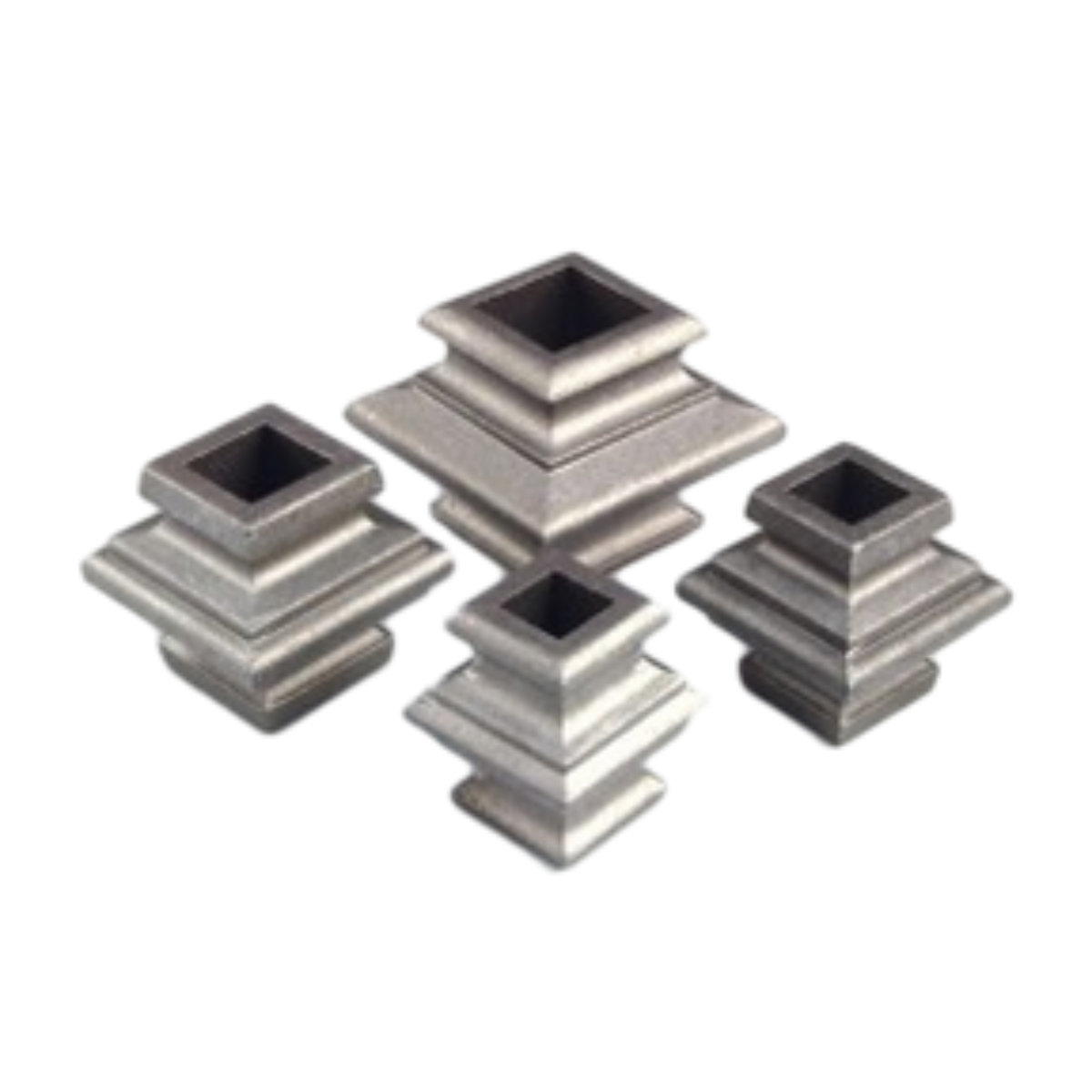

cast iron

Ironwork, a centuries-old craft, holds significant relevance in a wide array of modern applications, thanks to its combination of durability, versatility, and aesthetic appeal. As a cornerstone in construction and design, ironwork continues to evolve, integrating technological advancements and innovative designs that reflect both traditional craftsmanship and modern needs. This article delves into the multifaceted nature of ironwork, exploring its applications, craftsmanship, and the expertise required to master this enduring craft.

Trustworthiness in ironwork is paramount, as these structures often play critical roles in safety and functionality within public and private spaces. Certified ironworkers and companies uphold stringent standards, ensuring every piece meets the required safety regulations and performance specifications. The industry's commitment to quality and safety fosters public confidence and highlights the authoritative role that experienced professionals play in upholding these standards. The journey to becoming a master in ironwork is rigorous, involving formal apprenticeships and years of practice under seasoned mentors. Artisans gain hands-on experience and a deep understanding of the materials, tools, and techniques essential for producing high-quality iron products. This pathway not only equips them with the expertise needed to create enduring works of art and infrastructure but also instills a deep sense of pride and dedication to their craft. In today's market, the demand for sustainable construction practices is rising, and ironwork is playing a crucial role in this shift. Iron, particularly when recycled, presents an environmentally friendly option that reduces the strain on natural resources and promotes sustainability. By integrating sustainable practices, ironwork professionals contribute to the broader efforts of environmental conservation, further establishing their authoritative position within the field. For those seeking ironwork services, selecting a reputable practitioner ensures the receipt of high-quality, lasting products that perfectly blend functionality and aesthetics. Clients benefit from the real-world experience and technical expertise of seasoned professionals who continuously innovate and adapt to emerging industry trends. From personalized decorative pieces that reflect unique artistic visions to robust structural components that ensure safety and integrity, the offerings are vast and varied. In conclusion, the realm of ironwork is a testament to the enduring nature of traditional craftsmanship melded with modern innovation. The expertise and authoritative knowledge of skilled artisans continue to drive this industry forward, providing functional, aesthetic, and sustainable solutions across countless applications. As the demand for quality ironwork persists, the commitment to craftsmanship, learning, and sustainability remains steadfast, reinforcing the industry's vital role in shaping our built environment.

Trustworthiness in ironwork is paramount, as these structures often play critical roles in safety and functionality within public and private spaces. Certified ironworkers and companies uphold stringent standards, ensuring every piece meets the required safety regulations and performance specifications. The industry's commitment to quality and safety fosters public confidence and highlights the authoritative role that experienced professionals play in upholding these standards. The journey to becoming a master in ironwork is rigorous, involving formal apprenticeships and years of practice under seasoned mentors. Artisans gain hands-on experience and a deep understanding of the materials, tools, and techniques essential for producing high-quality iron products. This pathway not only equips them with the expertise needed to create enduring works of art and infrastructure but also instills a deep sense of pride and dedication to their craft. In today's market, the demand for sustainable construction practices is rising, and ironwork is playing a crucial role in this shift. Iron, particularly when recycled, presents an environmentally friendly option that reduces the strain on natural resources and promotes sustainability. By integrating sustainable practices, ironwork professionals contribute to the broader efforts of environmental conservation, further establishing their authoritative position within the field. For those seeking ironwork services, selecting a reputable practitioner ensures the receipt of high-quality, lasting products that perfectly blend functionality and aesthetics. Clients benefit from the real-world experience and technical expertise of seasoned professionals who continuously innovate and adapt to emerging industry trends. From personalized decorative pieces that reflect unique artistic visions to robust structural components that ensure safety and integrity, the offerings are vast and varied. In conclusion, the realm of ironwork is a testament to the enduring nature of traditional craftsmanship melded with modern innovation. The expertise and authoritative knowledge of skilled artisans continue to drive this industry forward, providing functional, aesthetic, and sustainable solutions across countless applications. As the demand for quality ironwork persists, the commitment to craftsmanship, learning, and sustainability remains steadfast, reinforcing the industry's vital role in shaping our built environment.

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters