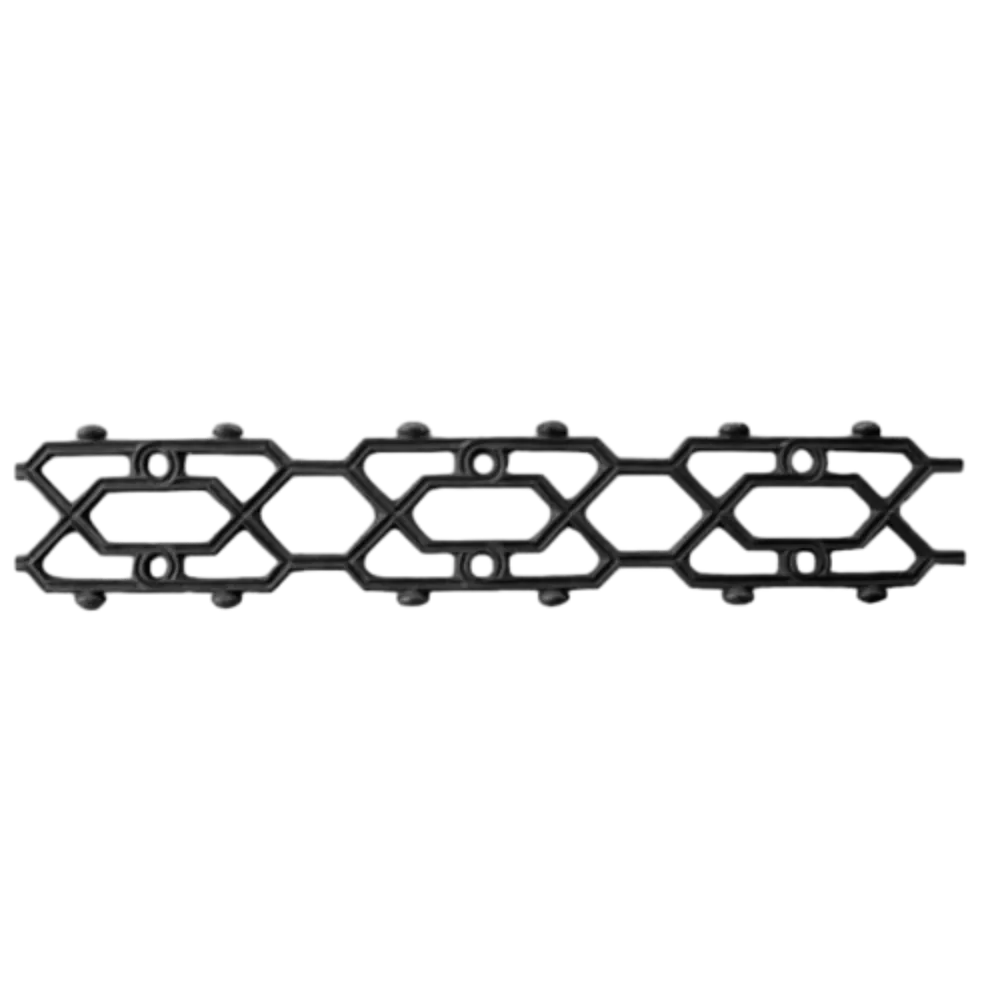

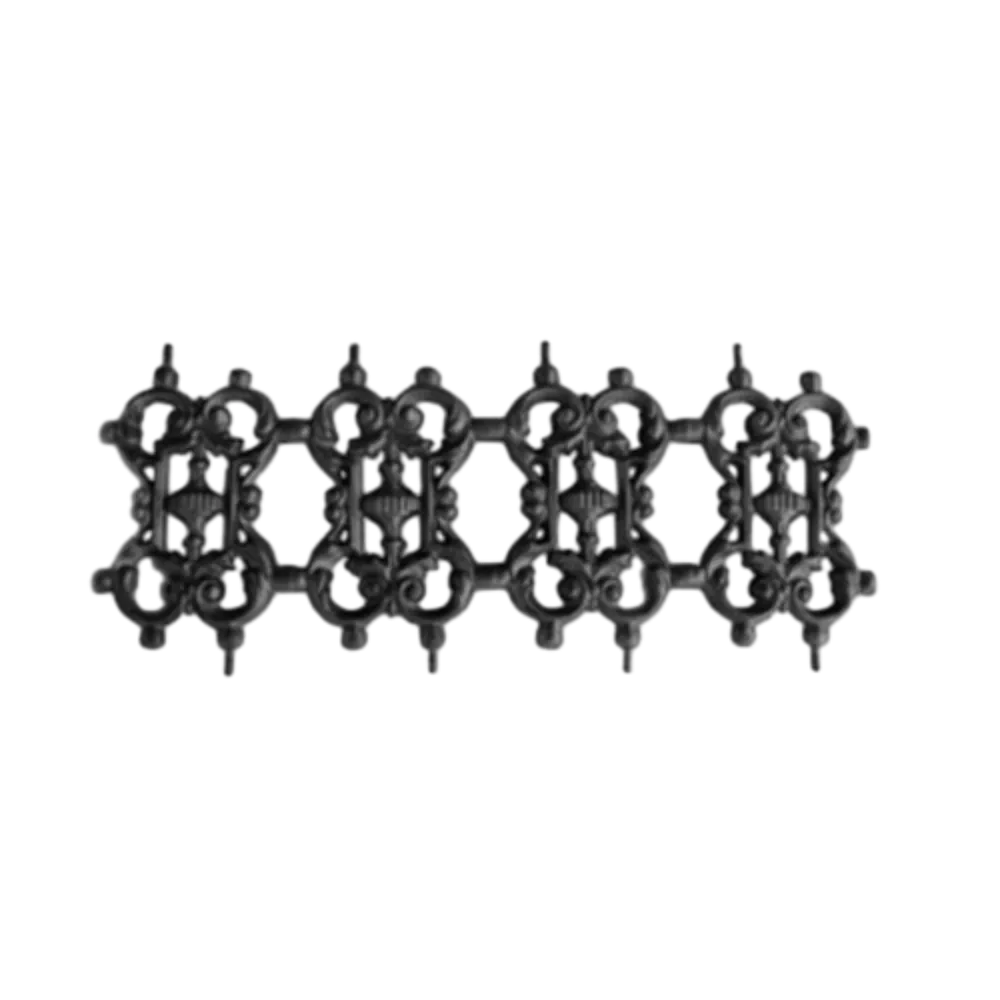

Cast Iron Panels for Sale – Decorative Railing & Balustrade Solutions

In the contemporary construction and architectural hardware industry, cast iron panels for sale are increasingly adopted in high-end balustrade, railing, and decorative projects. This comprehensive guide dives into their technical data, manufacturing flow, trend analysis, application scenarios, and procurement recommendations. Geared for architects, procurement specialists, and industry experts, it leverages data, in-depth comparisons, and practical cases to optimize your selection process.

According to a 2023 report by Zion Market Research, the global decorative iron panel market—spanning cast iron panels for sale, cast iron balustrade panels, cast iron decorative panels, decorative railing panels, and wrought iron railing panels—is projected to reach USD 2.46 billion by 2028 (source). Key drivers include rising demand for ornamental, long-life, and custom-fabricated architectural hardware.

In the last five years, the adoption of powder-coated, anti-corrosive, and CNC-precision castings has grown by over 34%.

| Model | Main Material | Finish/Coating | Process | Panel Size (mm) | Tensile Strength (MPa) | Corrosion Resistance (ASTM B117) | Application |

|---|---|---|---|---|---|---|---|

| JRC-CP600 | High-grade Cast Iron | Powder Coated | Casting + CNC | 900×250×30 | 265 | ≥500hrs (Grade 9) | Balustrade, Balcony |

| JRD-AP450 | Ductile Iron EN-GJS-400 | Polyester Painted | Sand Casting | 800×250×24 | 450 | ≥750hrs (Grade 10) | Garden Fence, Bridge Railing |

| JRO-DP950 | Wrought Iron | Hot-dip Galvanized | Forging + Laser Cutting | 950×180×18 | 370 | ≥980hrs (Grade 10) | Stair Rail, Architectural Facade |

The Cast Iron Railing Panel (cast iron panels for sale) is engineered for both performance and beauty, featuring intricate designs and exceptional mechanical properties. As an industry leader, we strictly conform to ISO 9001:2015 and ANSI A108 standards, providing excellence across architectural, residential, and industrial sectors.

- Material: EN-GJL-200, ASTM A48 Class 35B, or custom alloys for increased ductility and corrosion resistance.

- Surface Treatment: Multi-stage powder coating or custom painting, ensuring a 20+ year outdoor lifespan.

- Dimensional Tolerance: ±1mm (certified after CNC finishing).

- Quality Assurance: 100% ultrasonic flaw detection, surface hardness testing, and salt spray resistance up to 1,200 hours.

The journey of cast iron balustrade panels from design to finished product involves multilayered expertise and precise quality control:

Figure: Key nodes in cast iron decorative panel fabrication & QA workflow

- Design & Simulation: CAD/3D digital modeling, stress & fatigue FEA simulation.

- Molding: Auto-molding lines for sand or resin-bonded molds ensure repeatable precision (tolerance ≤1.2mm).

- Casting: High-temperature iron melt, poured at 1,370°C–1,420°C, ensuring uniform grain structure.

- Cooling & Shot-Blasting: Controlled cooling curve, then automated shot blasting removes residues and scales.

- CNC Finishing & Deflashing: Key surfaces precision-machined, critical edges deflashed to industry standards.

- Coating & Painting: Epoxy primer + powder/polyester topcoat, test compliance: ISO 9227/NACE TM0174 salt spray.

- Testing & Final Inspection: Load test (EN 1991 compliant), surface inspection, batch certification.

- Packing & Shipping: Anti-rust wrap, customized wood/pallet packaging, RFID tracking for quality chain-of-custody.

- Urban Railings & Balconies: Iconic residential towers in Dubai and Sydney utilize custom ornamental cast iron panels for both decor and building code compliance.

- Bridges & Heritage Sites: Preservation projects (UK, Italy) restore cast iron features with CNC-finished decorative railing panels, blending tradition and structural reliability.

- Commercial Landscapes: High-traffic zones (theme parks, government campuses) rely on hot-dip galvanized wrought iron railing panels for anti-corrosion and vandal-resistance.

- Industrial Platforms: Oil, petrochemical, metallurgy, and power plants specify ductile cast iron balustrade panels—assuring strength, fire resistance, and zero-maintenance longevity.

| Supplier | Product Grade | Main Markets | Certification | Custom Solutions | Lead Time | Warranty |

|---|---|---|---|---|---|---|

| JRCastings (China) | ISO9001, EN1090 | Global | CE, ISO 9001, SGS | Full (ODM/OEM) | 20–28 days | Up to 10 years |

| Ironart, UK | BS 4360/GR43A | Europe | CE | Partial | 30–45 days | 5 years |

| RailingCraft, USA | ASTM A48 CL35 | USA, Canada | ANSI, ISO | Full (OEM) | 25–35 days | 7 years |

Our Cast Iron Railing Panel lineup offers unmatched flexibility. From art-deco to modern minimalism, our team co-develops unique sketches or replicates historical designs. Key services include:

- CNC-Milled Detailing: 0.8mm minimum groove width for intricate patterns.

- Laser Logo Engraving: For heritage, branding, or project-specific motifs.

- Material Upgrades: Superior EN-GJS-500 ductile iron for critical load points, tested per ISO 6892-1.

- Color & Texture: Industry-best powder coating, 60+ standard RAL colors, and metallic textured options.

- Fixture Adaptation: Custom bolt plate, hidden anchor, or swing joint for on-site adaptability.

| Property | Cast Iron Railing Panel | Typical Market Panel |

|---|---|---|

| Yield Strength (MPa) | 265–450 | 180–320 |

| Surface Hardness (HB) | 158–188 | 131–162 |

| Salt Spray Resistance (h) | 900–1,200 | 350–600 |

| Dimensional Tolerance (mm) | ±1 | ±2.5 |

| Guaranteed Service Life (y) | 20–30 | 10–15 |

- Standard Production Cycle: 20–28 business days for bulk orders. Rush service available for urgent projects.

- Warranty Commitment: Up to 10 years on all cast iron panels for sale against breakage, corrosion, and manufacturing defects.

- After-Sales Support: 24/7 technical line & on-site troubleshooting. Installation guides/videos. Remote project consultation.

- Customization DFS: Each project receives a detailed datasheet, on-site compatibility service, and batch traceability.

- Certifications: ISO 9001, ISO 14001, EN 1090, SGS, ANSI, and more.

- “Decorative Ironwork for the 21st Century: Trends & Tests”, Iron & Steelworks Journal, 2023 (Read journal)

- “Practical Design and Durability for Exterior Cast Iron Applications”, Architectural Metalwork Forum, 2022 (View discussion)

- Zion Market Research, “Global Decorative Iron Panels: Market 2023–2028” (Market report)

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters