Jan . 22, 2025 01:46

Back to list

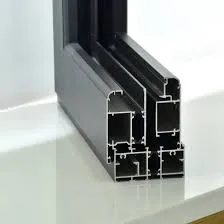

aluminium extrusion window frame

Aluminium extrusion window frames have revolutionized the industry with their unique blend of design flexibility, durability, and environmental sustainability. This innovative approach to window frame construction involves pushing heated aluminium through a die, producing lightweight, yet sturdy profiles that can be tailored to match any architectural requirement. This not only enhances the aesthetic appeal of structures but also significantly boosts their energy efficiency.

The expertise in producing aluminium extrusion frames lies in the precision and technology used in the manufacturing process. High-quality extruders employ cutting-edge techniques to ensure that each profile meets rigid specifications and quality standards. The meticulous process guarantees that the window frames not only meet but often exceed performance expectations in areas such as water resistance, thermal efficiency, and structural integrity. This dedication to precision and quality is why the best manufacturers are considered authoritative sources in the industry, trusted by architects and builders alike. Despite the many benefits, the trustworthiness of aluminium as a window frame material stems from its sustainable properties. Aluminium is abundantly available and, crucially, recyclable, allowing frames to be completely reprocessed at the end of their lifecycle without loss of quality. This recyclability supports a circular economy, reducing waste and conserving resources, which further enhances the eco-friendly credentials of aluminium extrusion window frames. Moreover, regulatory bodies across the world recognize and often mandate the use of materials that contribute toward sustainable construction practices. Aluminium extrusion frames meet these standards and are frequently seen in projects aiming for green building certifications, such as LEED or BREEAM. Manufacturers often provide detailed environmental product declarations and third-party certifications, bolstering the credibility and trust consumers place in using aluminium for their window framing needs. In conclusion, the move towards aluminium extrusion for window frames is not just a trend but a transition towards smarter, more sustainable construction practices. Its unique blend of durability, energy efficiency, and design flexibility make aluminium the preferred choice among contemporary builders and architects. Supported by both expertise in precise manufacturing techniques and recognized for their authoritative place in sustainable construction, aluminium extrusion window frames offer a reliable and forward-thinking solution for modern architectural challenges. By choosing aluminium, stakeholders are not just investing in the enduring strength of a material but also contributing positively to environmental sustainability efforts globally.

The expertise in producing aluminium extrusion frames lies in the precision and technology used in the manufacturing process. High-quality extruders employ cutting-edge techniques to ensure that each profile meets rigid specifications and quality standards. The meticulous process guarantees that the window frames not only meet but often exceed performance expectations in areas such as water resistance, thermal efficiency, and structural integrity. This dedication to precision and quality is why the best manufacturers are considered authoritative sources in the industry, trusted by architects and builders alike. Despite the many benefits, the trustworthiness of aluminium as a window frame material stems from its sustainable properties. Aluminium is abundantly available and, crucially, recyclable, allowing frames to be completely reprocessed at the end of their lifecycle without loss of quality. This recyclability supports a circular economy, reducing waste and conserving resources, which further enhances the eco-friendly credentials of aluminium extrusion window frames. Moreover, regulatory bodies across the world recognize and often mandate the use of materials that contribute toward sustainable construction practices. Aluminium extrusion frames meet these standards and are frequently seen in projects aiming for green building certifications, such as LEED or BREEAM. Manufacturers often provide detailed environmental product declarations and third-party certifications, bolstering the credibility and trust consumers place in using aluminium for their window framing needs. In conclusion, the move towards aluminium extrusion for window frames is not just a trend but a transition towards smarter, more sustainable construction practices. Its unique blend of durability, energy efficiency, and design flexibility make aluminium the preferred choice among contemporary builders and architects. Supported by both expertise in precise manufacturing techniques and recognized for their authoritative place in sustainable construction, aluminium extrusion window frames offer a reliable and forward-thinking solution for modern architectural challenges. By choosing aluminium, stakeholders are not just investing in the enduring strength of a material but also contributing positively to environmental sustainability efforts globally.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters