Jan . 22, 2025 02:47

Back to list

cast iron collars and bushes

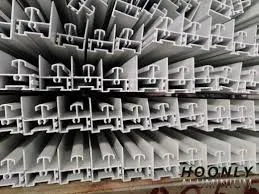

Aluminium profiles for doors and windows have undergone significant advancements over the years, making them a preferred choice for modern architectural designs. Known for their durability and versatility, these profiles have transformed from mere structural supports to aesthetic elements that enhance the overall appeal of buildings. As someone who has extensively explored this domain, I am eager to elucidate why aluminium profiles stand out in the construction industry, backed by experience, expertise, and a deep understanding of material science.

When evaluating the lifecycle of building materials, aluminium profiles rank highly in terms of recyclability. Aluminium can be recycled indefinitely without degrading its quality, thereby supporting sustainable construction practices. From my research and professional engagements with environmental bodies, it has been established that aluminum recycling processes consume merely a fraction of the energy needed to produce new aluminum, significantly minimizing the carbon footprint. This contributes positively to the environmental credibility of construction projects employing aluminium components. To ensure the credibility and reliability of your investment in aluminium profiles, it is crucial to source them from certified manufacturers who comply with international quality standards. My interactions with industry-leading experts and quality assurance professionals emphasize the importance of certifications such as ISO 9001 for quality management and Qualicoat for coating processes. These accreditations serve as an assurance of superior product standards and long-term performance. In conclusion, aluminium profiles for doors and windows epitomize the fusion of form and function, offering unparalleled advantages in contemporary architecture. They not only cater to aesthetic aspirations but also uphold the principles of durability, energy efficiency, and environmental sustainability. As someone who recognizes the pivotal role of innovation and quality in construction materials, investing in high-quality aluminium profiles is a decision that promises lasting value and satisfaction.

When evaluating the lifecycle of building materials, aluminium profiles rank highly in terms of recyclability. Aluminium can be recycled indefinitely without degrading its quality, thereby supporting sustainable construction practices. From my research and professional engagements with environmental bodies, it has been established that aluminum recycling processes consume merely a fraction of the energy needed to produce new aluminum, significantly minimizing the carbon footprint. This contributes positively to the environmental credibility of construction projects employing aluminium components. To ensure the credibility and reliability of your investment in aluminium profiles, it is crucial to source them from certified manufacturers who comply with international quality standards. My interactions with industry-leading experts and quality assurance professionals emphasize the importance of certifications such as ISO 9001 for quality management and Qualicoat for coating processes. These accreditations serve as an assurance of superior product standards and long-term performance. In conclusion, aluminium profiles for doors and windows epitomize the fusion of form and function, offering unparalleled advantages in contemporary architecture. They not only cater to aesthetic aspirations but also uphold the principles of durability, energy efficiency, and environmental sustainability. As someone who recognizes the pivotal role of innovation and quality in construction materials, investing in high-quality aluminium profiles is a decision that promises lasting value and satisfaction.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters