Top Manufacturers of Aluminium Window Profiles for Quality and Durability

The Rise of Aluminium Window Profile Manufacturers

In recent years, the construction and architectural design industries have seen a remarkable shift toward the utilization of aluminium window profiles

. This trend can be attributed to several factors, including durability, sustainability, aesthetic appeal, and energy efficiency. As a result, the market for aluminium window profile manufacturers has experienced significant growth, and many companies are innovating to meet the increasing demand.Aluminium, as a material, has numerous advantages over traditional alternatives like wood and PVC. One of its standout features is its durability. Aluminium window profiles are resistant to rust, corrosion, and weathering, making them suitable for various climates. They can withstand extreme temperatures and are less likely to warp or crack over time, ensuring that the windows maintain their functionality and appearance for decades. This longevity translates into cost savings for homeowners and builders alike, as it reduces the need for frequent replacements.

Another key benefit of aluminium window profiles is their environmental impact. As sustainability becomes a more pressing concern for many industries, aluminium stands out as a recyclable material. It can be recycled indefinitely without losing integrity or performance. Aluminium window manufacturers are increasingly adopting recycling practices to lower their carbon footprint and promote environmental responsibility. This focus on sustainability resonates with eco-conscious consumers, further bolstering the demand for aluminium options in the market.

In terms of aesthetics, aluminium window profiles offer versatility that is hard to match. They come in a wide variety of finishes, colors, and styles that can complement any architectural design. Homeowners can opt for sleek, modern designs, or they can choose more traditional appearances, all while maintaining the structural benefits of aluminium. The ability to customize ensures that window profiles can enhance the overall look of a building, whether residential or commercial.

aluminium window profile manufacturers

Energy efficiency is another area where aluminium window profiles have gained attention. With the rising costs of energy and an increasing awareness of climate change, energy-efficient products are in high demand. Modern aluminium windows can be fitted with thermal breaks to improve insulation, significantly reducing heat transfer. This means that homes equipped with these windows can maintain a comfortable indoor climate while consuming less energy for heating and cooling. Many manufacturers are now offering products that exceed the energy efficiency standards set by regulatory bodies, further encouraging their widespread adoption.

The competitive landscape of the aluminium window profile manufacturing industry is becoming increasingly dynamic. With several players entering the market, established companies are innovating their processes and products to retain their competitive edge. Investment in research and development is critical, as it allows manufacturers to improve formulation, strengthen profiles, and enhance production efficiency. Emphasis is also being placed on technology, with many companies integrating automation and smart technologies into their manufacturing processes.

Additionally, the global market is witnessing a surge in collaborations and partnerships among manufacturers, suppliers, and construction companies. Such alliances help streamline supply chains, reduce costs, and improve the quality of products. Countries with strong construction sectors, such as the United States, Germany, and China, are seeing substantial growth in their aluminium window profile markets.

Looking ahead, the future of aluminium window profile manufacturers appears bright. As urbanization continues and the demand for sustainable and aesthetically pleasing building options rises, the industry is well-poised for continued expansion. Manufacturers adapting to market trends and consumer preferences will not only thrive but also contribute to the evolution of modern architecture. The move toward aluminium is a testament to our capacity to innovate and embrace materials that enhance both function and style in the buildings of tomorrow.

-

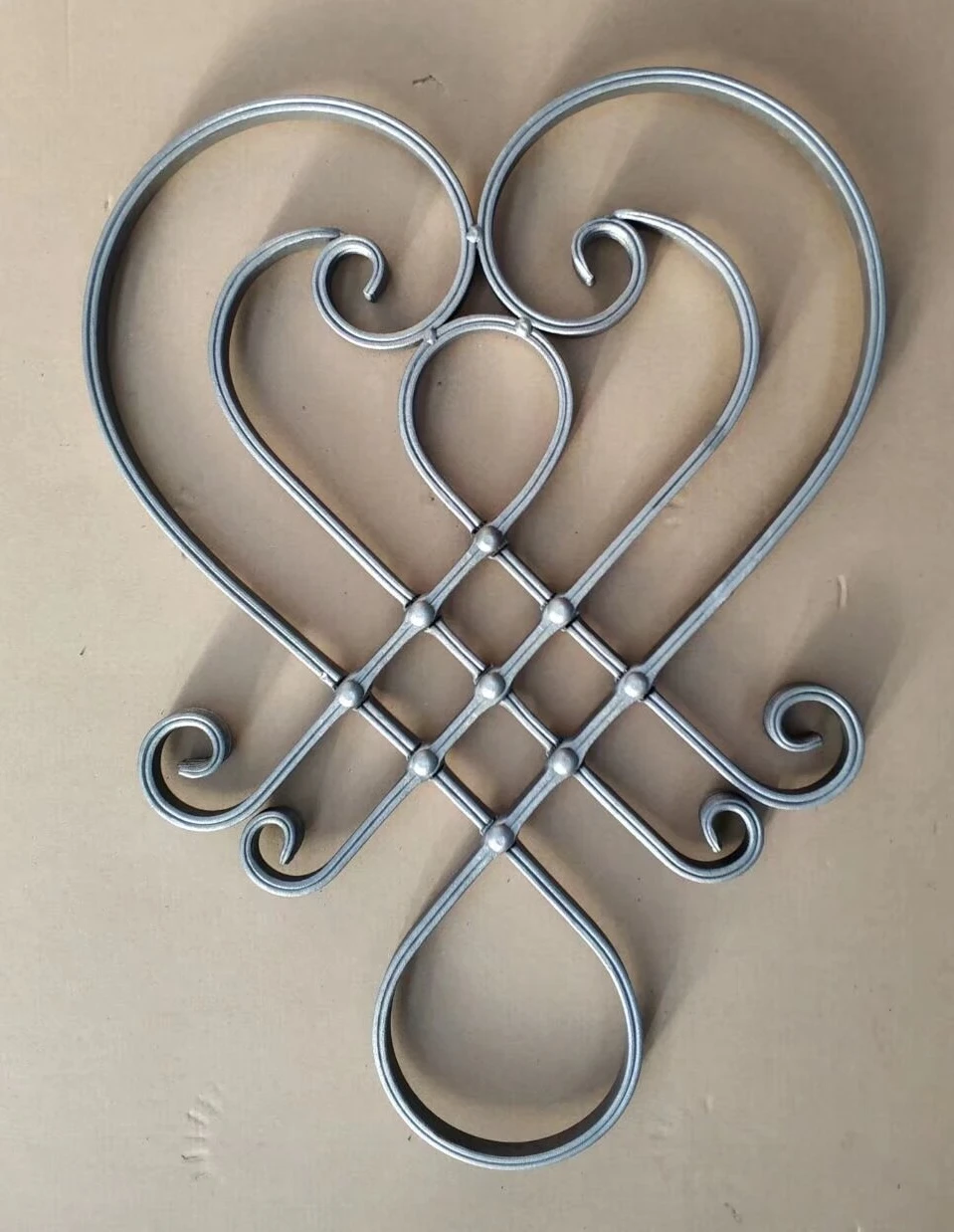

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters