aluminum window frame extrusions

The Versatility and Benefits of Aluminum Window Frame Extrusions

Aluminum window frame extrusions have become a popular choice for architects, builders, and homeowners alike. Their unique combination of durability, aesthetics, and sustainability contributes significantly to their widespread use in various types of construction projects. In this article, we will explore the advantages of aluminum window frame extrusions, their manufacturing process, and their application in modern architecture.

Understanding Aluminum Extrusions

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing heated aluminum through a die, which defines the shape of the extruded product. The process is highly versatile, allowing for the creation of complex profiles tailored to specific applications. For window frames, the ability to design intricate shapes provides both functional performance and aesthetic appeal.

Benefits of Aluminum Window Frame Extrusions

1. Durability and Longevity One of the primary reasons for using aluminum in window frames is its durability. Aluminum is highly resistant to corrosion, unlike other materials such as wood or steel. With proper finishing and maintenance, aluminum frames can last decades without significant degradation. This longevity translates to lower lifecycle costs, making aluminum a cost-effective option over time.

2. Lightweight yet Strong Aluminum is considerably lighter than steel, which simplifies the installation process and reduces the structural load of buildings. Despite being lightweight, aluminum possesses excellent strength-to-weight ratios, allowing for the construction of large, expansive window designs that do not compromise structural integrity.

3. Aesthetic Flexibility Aluminum extrusions offer a wide range of design possibilities. They can be powder-coated or anodized in various colors and finishes, allowing architects and designers the flexibility to match any building style. The sleek appearance of aluminum frames can enhance the overall visual appeal of a property, making them ideal for modern architectural designs.

4. Energy Efficiency Modern aluminum window frames can be designed with thermal breaks that significantly improve their energy efficiency. By incorporating insulating materials within the frame, energy loss through the windows can be minimized. This results in lower heating and cooling costs for homeowners and contributes to a more eco-friendly building design.

5. Sustainability Aluminum is a sustainable material; it is 100% recyclable without loss of properties. The recycling process requires just a fraction of the energy compared to primary aluminum production, thus significantly reducing the carbon footprint associated with window frames. Choosing aluminum for window frames supports eco-friendly construction practices and promotes sustainability in the building industry.

aluminum window frame extrusions

The Manufacturing Process

The manufacturing process of aluminum window frame extrusions involves several critical steps

1. Alloy Selection The choice of aluminum alloy is important as it affects the final product's strength and corrosion resistance. Common alloys used in window frames include 6061 and 6063, known for their excellent extrudability and surface finishing characteristics.

2. Heating and Extrusion The selected aluminum alloy is heated to a malleable state before being forced through a die. The extrusion process allows for the creation of customized profiles that meet specific requirements.

3. Cooling and Cutting Once the aluminum is extruded into the desired shape, it is rapidly cooled to solidify the structure. Afterward, the extrusions are cut to the required lengths for use in window frames.

4. Surface Treatment The extruded aluminum typically undergoes surface treatment, which may include anodizing or powder coating. These treatments enhance corrosion resistance and provide the desired aesthetic finish.

5. Assembly and Installation The final stage involves assembling the window components and installing them in the building. This stage is crucial as it determines the overall effectiveness and performance of the window system.

Conclusion

Aluminum window frame extrusions represent a fusion of functionality, aesthetics, and sustainability in modern architecture. Their numerous advantages—ranging from strength and durability to energy efficiency—make them a preferred choice for construction projects worldwide. As the industry continues to prioritize eco-friendly materials, aluminum's recyclability reinforces its position as a champion of green building practices. Whether for residential or commercial applications, aluminum window frame extrusions are set to remain a cornerstone of contemporary design and construction.

-

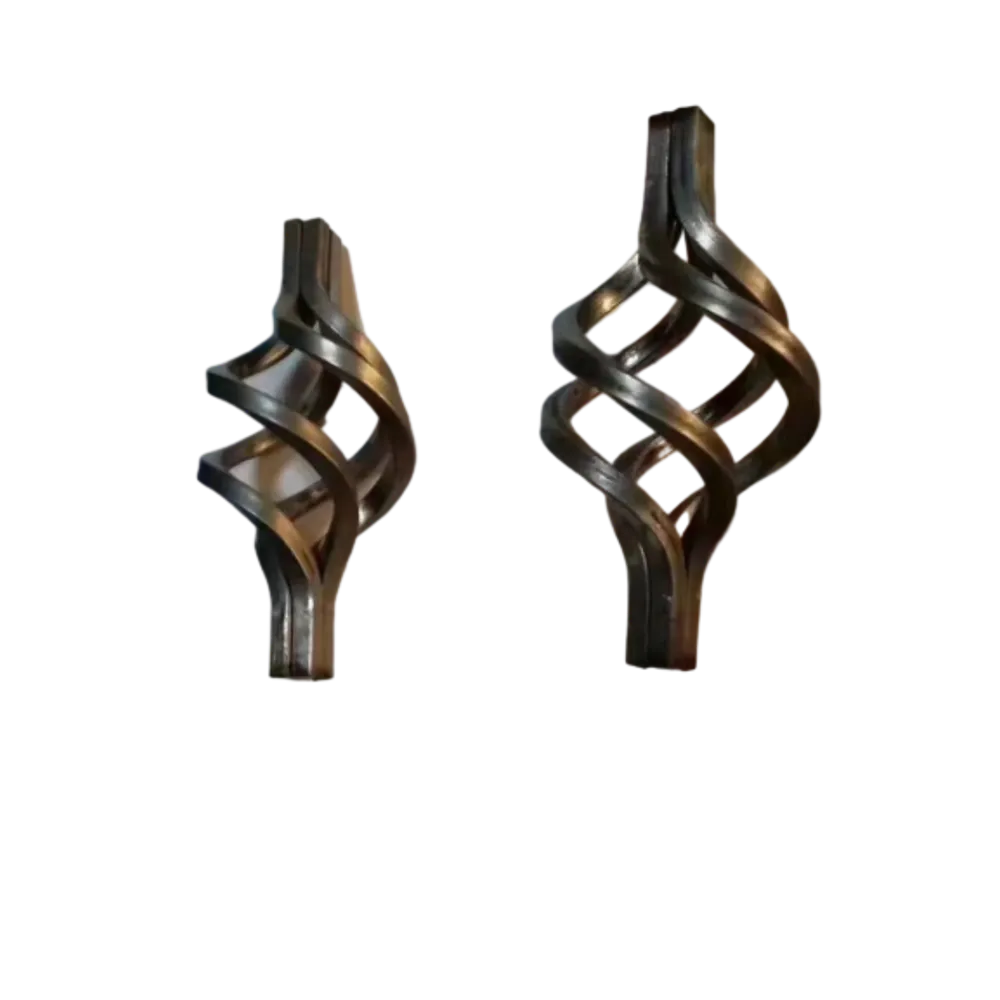

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters