Exploring Innovative Designs in Cantilever Wheel Technology for Enhanced Performance and Stability

The Evolution and Significance of Cantilever Wheels

Cantilever wheels have emerged as a crucial innovation in the realm of engineering and design, encompassing a range of applications from automotive to aerospace. This specialized wheel design utilizes a protruding support structure, allowing for enhanced stability and performance, which has captured the attention of engineers and enthusiasts alike.

Understanding Cantilever Wheels

At its core, a cantilever wheel operates on the idea of leveraging support while minimizing the associated weight. A cantilever system consists of a beam supported at one end and free at the other, which is precisely what these wheels embody. This design allows for greater flexibility in terms of load distribution, making them particularly effective for applications that demand high performance and reliability.

The basic principle behind cantilever wheels is to reduce unnecessary mass while providing maximum support. Traditional wheel designs often distribute stress evenly across their structure, but cantilever wheels direct forces to the most durable sections. As a result, manufacturers can create wheels that are less susceptible to warping or damage over time, extending the lifespan of the product.

Applications Across Various Industries

The versatility of cantilever wheels makes them indispensable in multiple sectors. In the automotive industry, they have been adapted for use in high-performance vehicles, where weight reduction is critical for achieving better fuel efficiency and speed. Racing cars utilize cantilever wheels to enhance cornering capabilities, allowing drivers to navigate sharp turns with precision.

In aerospace engineering, cantilever wheels offer significant advantages. Aircraft landing gear systems use a cantilever design to support the fuselage’s weight effectively during landings. By minimizing shock absorption and distributing the weight evenly during landing, these wheels help protect the integrity of the aircraft while ensuring passenger safety.

The manufacturing and robotics sectors also benefit from cantilever wheels

. Automated systems use these wheels in conveyor belts and robotic arms, relying on their stability and efficiency to transport materials or assemble components. Their unique design allows for smoother movement along tracks, minimizing friction and energy use.cantilever wheels

Innovations and Advancements

Recent advancements in materials science have revolutionized cantilever wheel designs. The introduction of lighter yet stronger materials such as carbon fiber and advanced alloys has helped engineers push the boundaries of what was previously possible. These innovations have led to wheels that not only perform better but are also more environmentally friendly, as they contribute to overall energy efficiency in various applications.

Furthermore, computer-aided design (CAD) has enabled precision in creating cantilever wheels tailored for specific tasks or environments. Designers can simulate various load conditions, ensuring that the wheels can withstand the rigors of their intended applications. This technological synergy has propelled the development of bespoke solutions that cater to distinct industry requirements.

Sustainability and Future Trends

As the push for sustainability continues to grow, the future of cantilever wheels looks promising. Manufacturers are increasingly focusing on producing wheels that have lower environmental impacts, both during production and throughout their lifecycle. The shift towards recyclable materials and sustainable manufacturing processes aligns with global goals for reducing carbon footprints.

Moreover, the integration of smart technology into cantilever systems is an exciting prospect. Sensors and IoT (Internet of Things) technology can be embedded into wheel designs to monitor performance in real-time, providing valuable data that can inform maintenance and improve safety protocols. This data-driven approach can lead to more innovative designs and further enhance the capabilities of cantilever wheels.

Conclusion

Cantilever wheels represent a paradigm shift in engineering design, combining functionality with innovative technology. Their applications across various industries showcase their significance in enhancing performance while reducing weight and maximizing efficiency. As research continues into materials and design methodologies, the future of cantilever wheels promises even greater advancements that will undoubtedly lead to improved outcomes in many sectors. Whether it's on the racetrack, in the skies, or within automated environments, cantilever wheels are set to remain at the forefront of engineering innovation, paving the way for a more efficient and sustainable future.

-

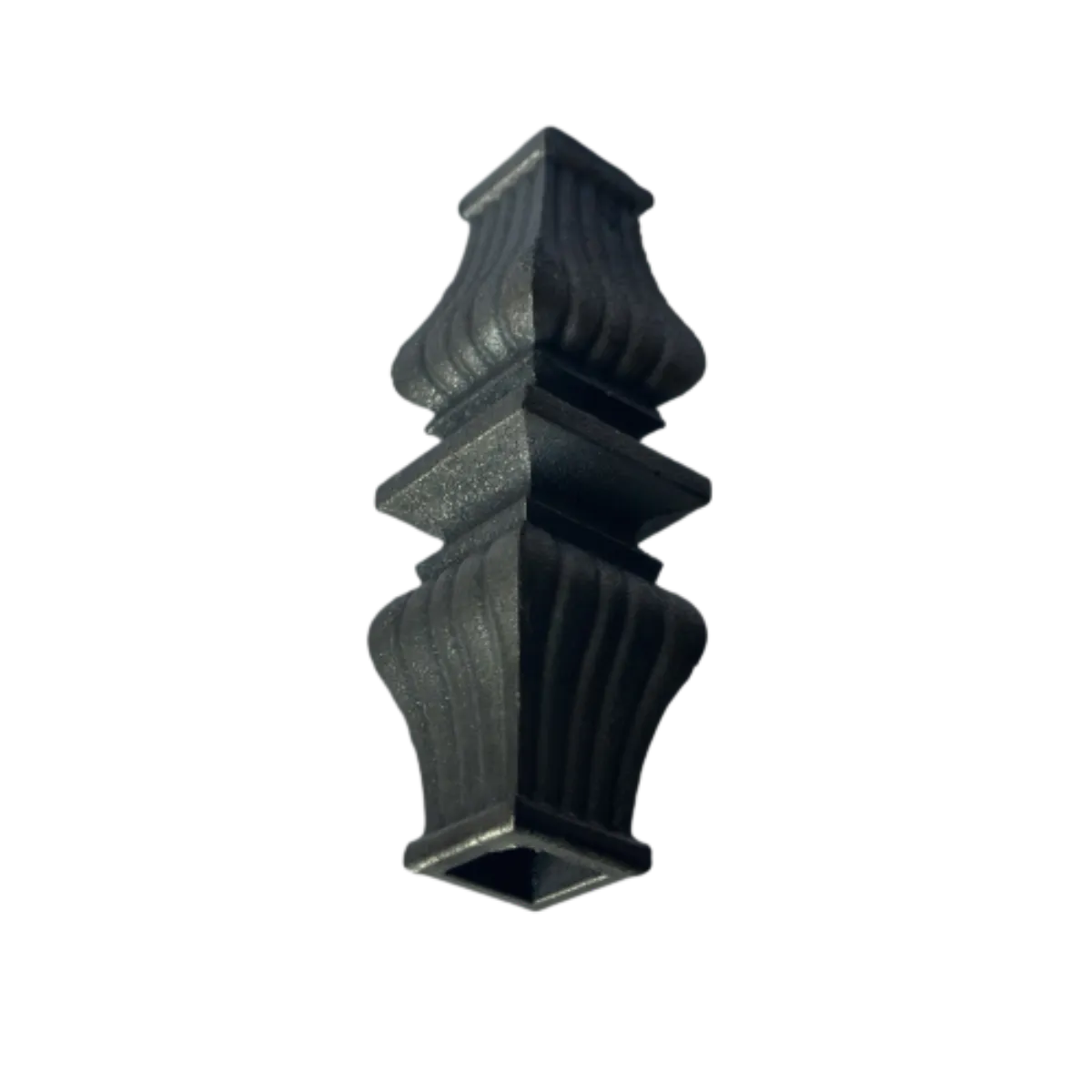

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters