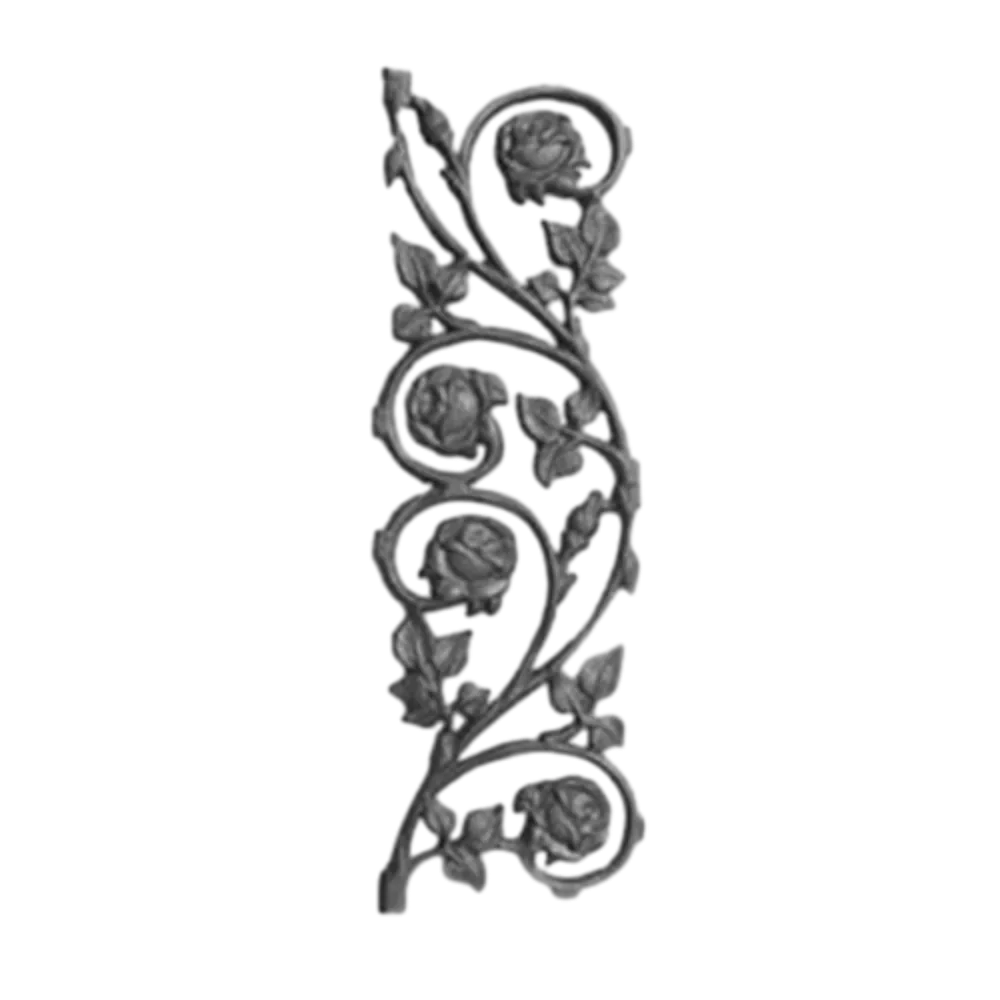

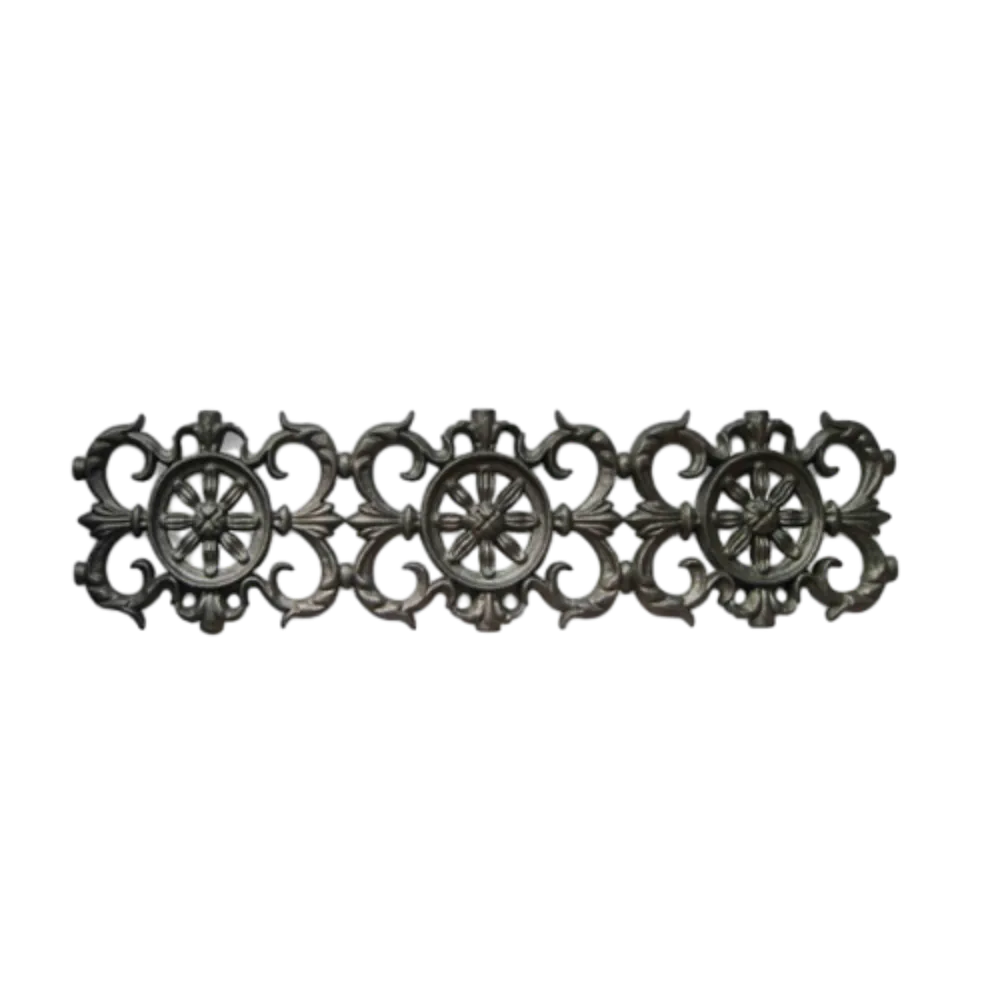

Cast Iron Panel – Durable, Ornate, Custom Railing Panels

Cast Iron Railing Panel: durability, pattern detail, and a bit of old-world charm

If you’ve ever run your hand over a well-made railing insert, you know the feeling—cool, solid, and reassuring. The [Cast Iron Panel] from Shijiazhuang, Hebei (a region that knows foundry craft) keeps showing up in restoration projects, boutique hotels, and even modern townhouses. To be honest, it’s not just nostalgia—cast iron still punches above its weight in longevity and detail.

What’s trending in cast iron railings

Two currents, oddly paired: preservation and prefab. Heritage projects want period-correct scrollwork (no compromises), while new builds lean on repeatable modules to control cost. Powder coating has taken center stage; hot-dip galvanizing plus topcoat is the belt-and-suspenders approach for coastal or high-salt areas. Many customers say they prefer pre-primed panels to streamline site installation.

Technical snapshot

| Product | Cast Iron Railing Panel (Cast Iron Panel) |

| Size / Weight | H740 × 230 mm, ≈4 kg |

| Origin | Shijiazhuang, Hebei Province, China |

| Material grade | Grey cast iron EN-GJL-200 (EN 1561) ≈ ASTM A48 Class 30 |

| Finish options | As-cast + primer; powder coat 60–90 μm; hot-dip galvanizing (ISO 1461) + topcoat |

| Dimensional tolerance | Around ±1.5–2.0 mm (real-world use may vary by pattern complexity) |

| Service life (indicative) | Painted: 15–25 yrs; HDG + topcoat: 25–35+ yrs depending on environment |

From melt to balcony: the process (short version)

Materials: pig iron + quality scrap, carbon ~3.2%, silicon ~2.0%, controlled S/P. Melting via medium-frequency induction furnaces; pour temp typically 1350–1400°C. Patterns are molded in green sand. After shakeout, parts are shot-blasted, gates ground, and edges deburred. Coatings follow: zinc (ISO 1461) where specified, then primer/powder. QC uses spectrometry for chemistry, hardness checks (HB 170–220), visual inspection for blowholes, and coating thickness via ISO 2178. Corrosion testing often references ISO 9227 salt spray; we’ve seen 240–480 h pass reports on powder-coated galvanized panels, which is solid for urban installs.

Where people actually use them

- Residential balconies and stair balustrades

- Historic restorations (Victorian/Art Nouveau vibes)

- Hotels and cafes—fast aesthetic uplift without custom forging

- Municipal parks, garden fencing, patio dividers

Advantages (why this over fabricated steel?)

Pattern fidelity is superb—castings capture relief and curves that flat steel can’t, at least not without punishing labor. Also, grey iron’s damping reduces “ringing” on contact. Cost per ornament tends to beat hand-forged equivalents. The flip side? It’s brittle compared with low-carbon steel, so design for decorative infill rather than primary barrier loads (check BS 6180/EN barriers guidance for your region).

Vendor comparison (quick take)

| Vendor | Material/Finish | Lead time | Certs | Notes |

|---|---|---|---|---|

| TJJ Iron Casting (Hebei) | EN-GJL-200; primer/powder; HDG+topcoat | ≈20–35 days | ISO 9001; EN 1561 compliance | Stable patterns; small MOQs possible |

| Vendor B (EU) | Grey iron; powder coat | ≈4–6 weeks | ISO 9001 | Higher unit cost; quick freight |

| Vendor C (Global) | Mixed grades; paint only | ≈30–45 days | — | Budget-friendly; variable QC |

Customization

Send DWG/DXF or even a sketch—patterns can be tweaked for hole centers, scroll thickness, and mounting tabs. OEM/ODM is common; logos or project codes get cast discreetly on the back. For coastal work, specify HDG + powder; for heritage, matte black with light texture reads best (subjective, I know).

Field notes (mini case)

A boutique hotel retrofit in Marseille used 180 pieces of Cast Iron Panel modules. Coating stack: HDG per ISO 1461, epoxy primer, polyester topcoat (≈80 μm total paint). Site tests showed no blistering after 480 h ISO 9227 NSS; adhesion ASTM D3359 at 4B–5B. The installer told me, “Pattern repeat was tight, barely any on-site shimming.” That’s what you want on level 3 stairs with guests arriving tomorrow.

Final thought

The Cast Iron Panel isn’t trying to be structural steel. It’s decorative infill that lasts, looks right, and installs predictably. Pick your finish for the environment, and it’ll age gracefully—like many good things in iron.

Authoritative references

- EN 1561:2011 Founding — Grey cast iron (CEN)

- ASTM A48/A48M-20 Standard Specification for Gray Iron Castings (ASTM International)

- ISO 1461:2022 Hot dip galvanized coatings on fabricated iron and steel articles (ISO)

- ISO 9227:2017 Corrosion tests in artificial atmospheres — Salt spray tests (ISO)

- BS 6180:2011 Barriers in and about buildings — Code of practice (BSI)

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges