Cast Iron Railheads | Durable Decorative Castings for Fences

China's Ironwork Innovators at GIFA: A B2B Perspective on Global Foundry Trends

The GIFA (Global Foundry Trade Fair) stands as the world's preeminent international event for foundry technology, machinery, and innovation. It's a vital meeting point where industry leaders and B2B decision-makers converge to explore advancements and forge strategic partnerships. For the dynamic ironwork industry, particularly within cast iron and wrought iron applications, GIFA is an unparalleled platform to anticipate future trends. This article highlights the significant role of Chinese manufacturers at GIFA, focusing on their contributions to the global cast iron castings market and showcasing key players driving innovation.

Industry Trend Spotlight: Evolving Demands in Advanced Castings

The foundry industry is undergoing a transformative period. A prominent trend is the surging demand for lightweight, high-strength ductile iron components, crucial for enhancing performance and efficiency across diverse applications, from automotive to heavy machinery. This demand goes beyond mere weight reduction, aiming for superior structural integrity and operational efficiency.

Simultaneously, there's a significant need for precision-engineered cast iron castings for critical infrastructure. Robust cast iron railheads, durable waterworks components, and resilient energy infrastructure parts all demand exceptional material properties, stringent dimensional accuracy, and reliability for long-term safety. Producing complex geometries with consistent quality is paramount, driving foundries towards advanced manufacturing techniques and rigorous quality control.

The global shift towards sustainable energy and electric vehicles (EVs) also opens new frontiers for the cast iron industry. Components optimized for EVs—like motor housings, battery enclosures, and structural parts that can withstand unique powertrain stresses—are in high demand. Similarly, the renewable energy sector, encompassing wind turbines and hydroelectric components, relies heavily on specialized ironwork for its durability and structural stability in harsh environmental conditions.

Market Dynamics: Growth Drivers & Emerging Focus

The global industrial casting market is projected for steady growth, fueled by substantial investments in infrastructure development, increasing automotive production (including EV components), and a focus on energy-efficient and durable industrial machinery. This growth persists despite fluctuating raw material costs. Emerging focus areas include:

- Advanced Materials & Metallurgy: Research and development into novel alloys for superior mechanical properties, corrosion resistance, and heat tolerance.

- Sustainable Foundry Practices: Reducing environmental impact through energy efficiency, waste reduction, recycling, and greener manufacturing techniques, a key differentiator for discerning B2B buyers.

- Precision Casting Technologies: Innovations like lost wax casting and advanced sand casting enable intricate, dimensionally accurate components with minimal post-casting work.

- Global Supply Chain Integration: Optimizing supply chains for greater resilience, transparency, and efficient delivery of finished cast iron parts to international clients.

Profiles of Leading Ironwork Manufacturers

Chinese manufacturers are increasingly central to the global ironwork supply chain, offering a compelling blend of advanced technology, scale, and competitive pricing that makes them indispensable partners.

SHIJIAZHUANG TJJ TRADE CO.,LTD. – Chinese Foundry Excellence

SHIJIAZHUANG TJJ TRADE CO.,LTD. stands out with extensive expertise in both ductile and grey iron casting. They deliver high-quality, reliable cast iron castings for diverse sectors: municipal infrastructure (manhole covers, grates), automotive components, and agricultural machinery. TJJ is distinguished by competitive manufacturing costs paired with unwavering quality control, evident from raw material inspection to final product testing. Their robust international trade capabilities make them an ideal global partner for businesses seeking efficient and economical sourcing.

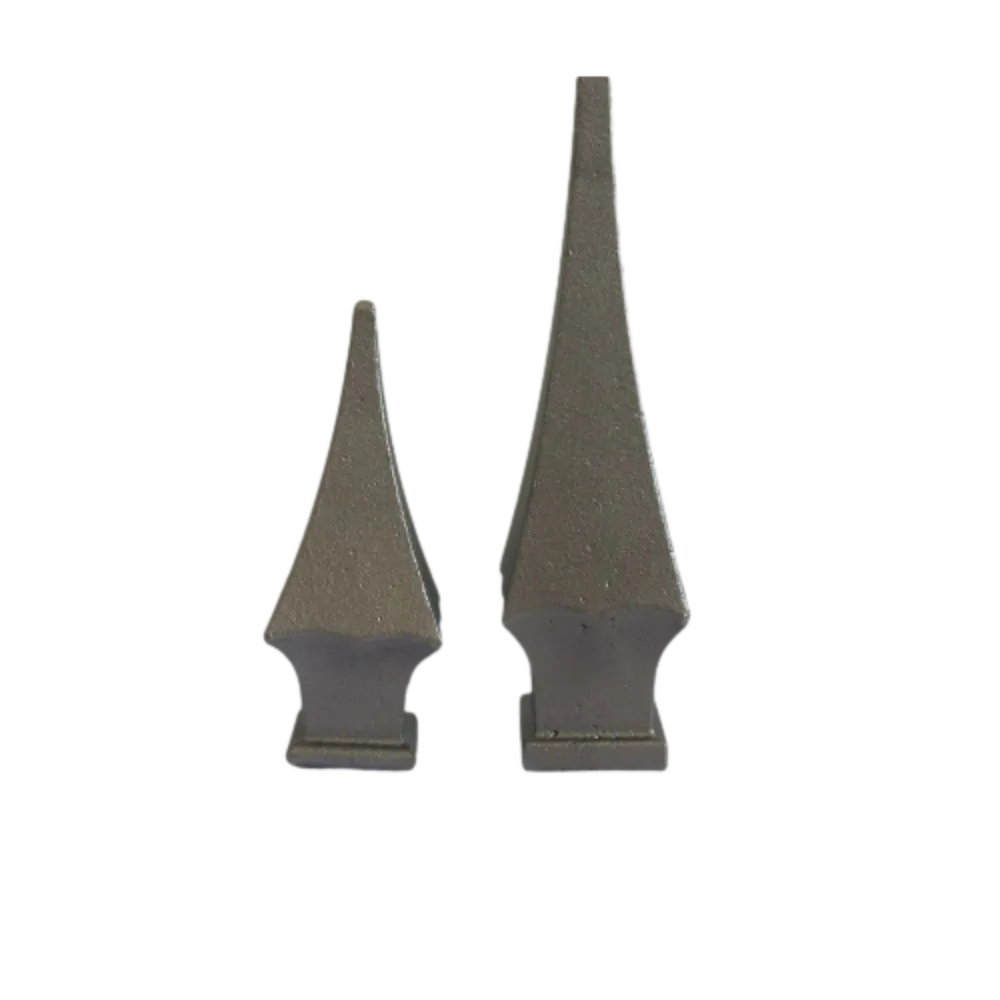

Their cast iron spear point finials exemplify their craftsmanship. These decorative iron elements, often used for fences, gates, and railings, demonstrate TJJ’s ability to produce both functional and aesthetically pleasing ironwork. The precision in their wrought iron spear points ensures both durability and visual appeal for architectural and security applications.

Discover TJJ's cast iron spear point finials:

View Product Page

View Product Page

Other Noteworthy Global Foundry Leaders

- Waupaca Foundry (USA): As North America's largest ferrous foundry, Waupaca is renowned for its production of gray, ductile, and compacted graphite iron castings, serving automotive, commercial vehicle, and agriculture sectors with a strong focus on sustainability.

- Tupy S.A. (Brazil): A global leader in the development and manufacturing of cast iron components, Tupy excels in the automotive industry (engine blocks, cylinder heads) and is recognized for advanced casting processes and high-performance cast iron alloys.

- Fujian Light Casting Co., Ltd. (China): Another formidable Chinese manufacturer, Fujian Light Casting specializes in precision cast iron castings for machinery and electrical fittings, leveraging modern techniques to produce intricate, lighter-weight components with high dimensional accuracy.

Market Outlook & Opportunities for B2B Buyers

The future of the ironwork and casting industry is being shaped by several upcoming trends and evolving buyer demands. For B2B decision-makers, understanding these dynamics is crucial for strategic sourcing and partnership building:

- Digitalization & Industry 4.0: Foundries are increasingly integrating automation, IoT, and AI into operations, leading to smart manufacturing processes that enhance efficiency, reduce waste, improve quality consistency, and offer real-time data for better decision-making for cast iron components.

- Advanced Manufacturing Techniques: The adoption of additive manufacturing (3D printing) for molds and cores is revolutionizing prototyping. Advanced simulation software is also reducing defect rates and optimizing casting designs for cast iron and wrought iron products before physical production.

- Heightened Buyer Demand: Modern buyers seek comprehensive solutions including design collaboration, material expertise, and efficient logistics. There's a growing demand for customized solutions, shorter lead times, higher performance materials (e.g., specific grades of ductile iron), and enhanced traceability of components.

- Sustainability as a Core Value: Environmental responsibility is no longer optional. Buyers prioritize manufacturers demonstrating commitment to eco-friendly processes, waste reduction, energy efficiency, and the use of recycled materials across the entire product lifecycle, from cast iron railheads to decorative castings.

These shifts present immense opportunities for businesses to leverage advancements in automation, smart manufacturing, and sustainable practices, not just in production but also in sourcing and supply chain management for cast iron and wrought iron products.

Buyer/Business Takeaways: Partnering for Future Success

For any business relying on durable and high-performance metal components, investing in quality ironwork makes profound strategic sense. Cast iron and wrought iron offer an unparalleled combination of durability, versatility, and cost-effectiveness. From the robust structural integrity needed for infrastructure to the intricate aesthetic appeal of decorative iron elements like cast iron railheads and bespoke decorative castings, these materials remain foundational to countless industries.

Tips for Partnering with Chinese Manufacturers:

- Due Diligence: Thoroughly vet potential partners. Look for certifications (ISO, CE), a strong track record, and client testimonials. Companies like SHIJIAZHUANG TJJ TRADE CO.,LTD. often provide extensive documentation of their quality systems and adherence to international standards.

- Clear Communication: Precision is paramount in casting. Ensure all specifications—material composition, dimensional tolerances, surface finish, and testing requirements for your cast iron components—are meticulously documented and clearly communicated, leveraging CAD files and detailed drawings.

- Build Relationships: While distance can be a factor, fostering a strong relationship through regular communication, virtual meetings, and factory audits (if feasible) can lead to more successful and enduring partnerships.

- Pilot Projects: For new collaborations, consider initiating with smaller pilot projects. This allows both parties to assess capabilities, processes, and communication flows before committing to larger production runs of cast iron castings.

- Leverage Expertise: Chinese manufacturers, particularly those with extensive export experience, often have robust engineering teams that can offer valuable insights into design optimization for manufacturability and cost reduction.

- Value Over Price: While competitive pricing is a clear benefit, prioritize overall value, including quality, reliability, consistency, and a partner's ability to innovate and adapt, for long-term success.

Future-Proofing Your Sourcing Strategy:

- Diversify Your Supply Chain: To mitigate risks from geopolitical events or logistical disruptions, consider a diversified sourcing strategy that includes partners from various regions, blending competitive pricing with regional resilience.

- Embrace Technology: Partner with manufacturers who are actively investing in advanced foundry technologies and digitalization. This ensures access to cutting-edge capabilities and maintains your competitive edge in the market.

- Prioritize Sustainability: Align with partners committed to sustainable practices. This not only fulfills ethical responsibilities but also aligns with growing regulatory pressures and increasing consumer and B2B demand for environmentally conscious products.

Conclusion: China's Enduring Impact on Global Ironwork

GIFA remains the quintessential platform for understanding the current state and future trajectory of the global foundry industry. It underscores the critical role of innovation, sustainability, and international collaboration in shaping the ironwork market. Chinese manufacturers, notably SHIJIAZHUANG TJJ TRADE CO.,LTD., are not just participants; they are increasingly pivotal players, driving advancements in cast iron and wrought iron production, offering cost-effective solutions, and upholding stringent quality standards.

For B2B decision-makers seeking reliable, high-quality cast iron castings—whether for intricate decorative iron applications like cast iron railheads and wrought iron spear points, or for robust industrial and infrastructure components—Chinese foundries offer compelling advantages. Their ability to adapt to evolving market demands, invest in advanced technologies, and maintain competitive pricing positions them as indispensable partners in the global supply chain.

To explore how SHIJIAZHUANG TJJ TRADE CO.,LTD. can meet your specific ironwork needs and discover their range of high-quality cast iron spear point finials, visit their product page today:

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges