Feb . 18, 2025 04:55

Back to list

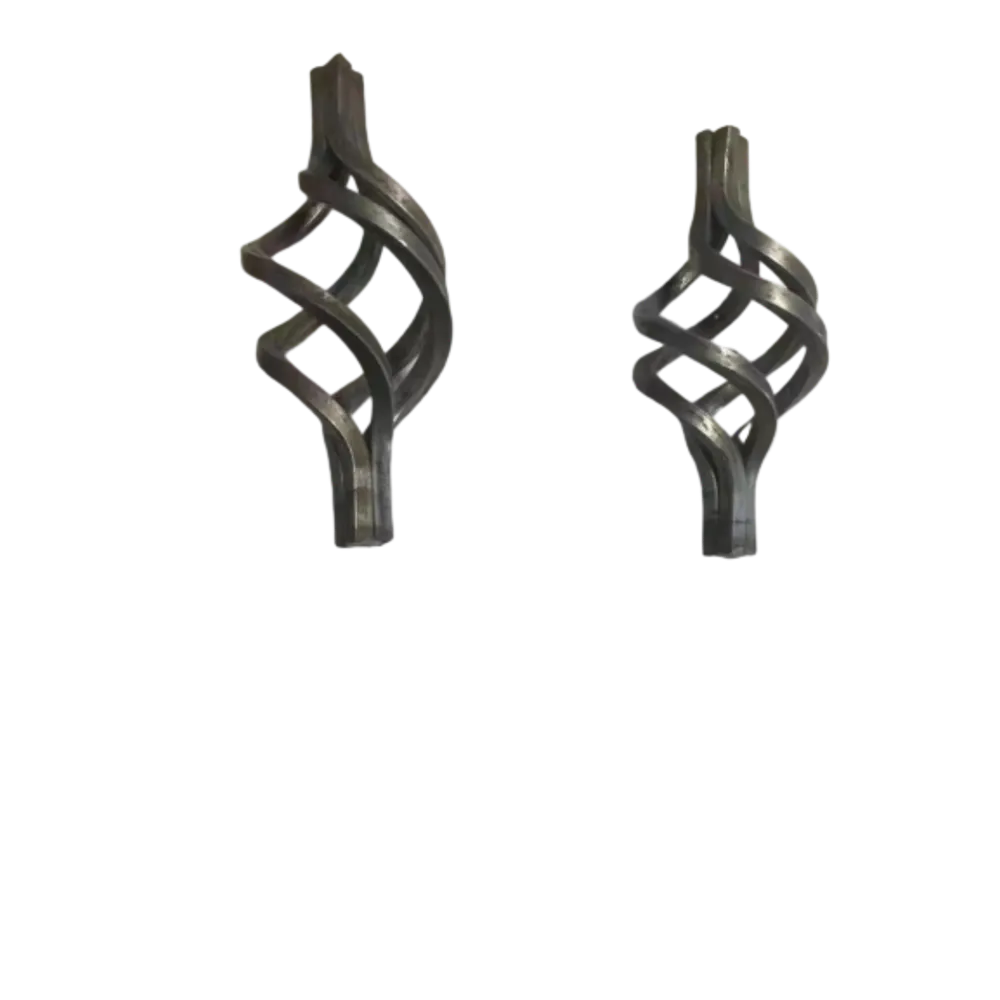

cast iron ball point

When it comes to industrial machinery, mining operations, or construction, the choice of materials is vital to ensure efficiency, durability, and safety. One often overlooked yet crucial component in these sectors is the cast iron ball point. Despite its simplicity, the cast iron ball point plays a significant role in various applications, thanks to its robust qualities and mechanical properties.

Moreover, the cost-effectiveness of cast iron ball points makes them an economically viable choice. While materials like stainless steel or titanium might offer specific advantages, they come with a significantly higher price tag. Cast iron, on the other hand, combines both performance and affordability, catering to industries that require bulk production without compromising on quality. For businesses operating on a tight budget, this cost efficiency can result in substantial savings, allowing investment in other critical areas without sacrificing equipment reliability. In terms of authoritative credibility, many leading industrial equipment manufacturers certify their products to international standards, ensuring that components like cast iron ball points meet rigorous quality benchmarks. Certifications from organizations such as ISO and ASTM add an extra layer of trust, assuring clients and industries that the components will perform as expected under demanding conditions. This trustworthiness is further bolstered by partnerships with established metallurgical laboratories and universities that continuously conduct studies and tests, validating the effectiveness and safety of cast iron in various applications. From an experiential perspective, countless case studies highlight the successful deployment of cast iron ball points across diverse industries. Mining operations, in particular, have lauded the material for its contribution to reducing maintenance cycles and enhancing machinery uptime. Field reports frequently cite fewer machine stoppages and extended periods between parts replacements, reflecting the tangible benefits of using cast iron. In conclusion, the cast iron ball point is more than just a component; it is a testament to human ingenuity and the evolution of material sciences. Its blend of durability, expertise in production, cost-effectiveness, and authoritative backing through certifications marks it as a cornerstone in the industrial world. Businesses opting for cast iron ball points are truly investing in a solution that promises performance, reliability, and trustworthiness. In a competitive market where every element counts, the right choice of materials can be the difference between operational success and costly setbacks.

Moreover, the cost-effectiveness of cast iron ball points makes them an economically viable choice. While materials like stainless steel or titanium might offer specific advantages, they come with a significantly higher price tag. Cast iron, on the other hand, combines both performance and affordability, catering to industries that require bulk production without compromising on quality. For businesses operating on a tight budget, this cost efficiency can result in substantial savings, allowing investment in other critical areas without sacrificing equipment reliability. In terms of authoritative credibility, many leading industrial equipment manufacturers certify their products to international standards, ensuring that components like cast iron ball points meet rigorous quality benchmarks. Certifications from organizations such as ISO and ASTM add an extra layer of trust, assuring clients and industries that the components will perform as expected under demanding conditions. This trustworthiness is further bolstered by partnerships with established metallurgical laboratories and universities that continuously conduct studies and tests, validating the effectiveness and safety of cast iron in various applications. From an experiential perspective, countless case studies highlight the successful deployment of cast iron ball points across diverse industries. Mining operations, in particular, have lauded the material for its contribution to reducing maintenance cycles and enhancing machinery uptime. Field reports frequently cite fewer machine stoppages and extended periods between parts replacements, reflecting the tangible benefits of using cast iron. In conclusion, the cast iron ball point is more than just a component; it is a testament to human ingenuity and the evolution of material sciences. Its blend of durability, expertise in production, cost-effectiveness, and authoritative backing through certifications marks it as a cornerstone in the industrial world. Businesses opting for cast iron ball points are truly investing in a solution that promises performance, reliability, and trustworthiness. In a competitive market where every element counts, the right choice of materials can be the difference between operational success and costly setbacks.

Prev:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters