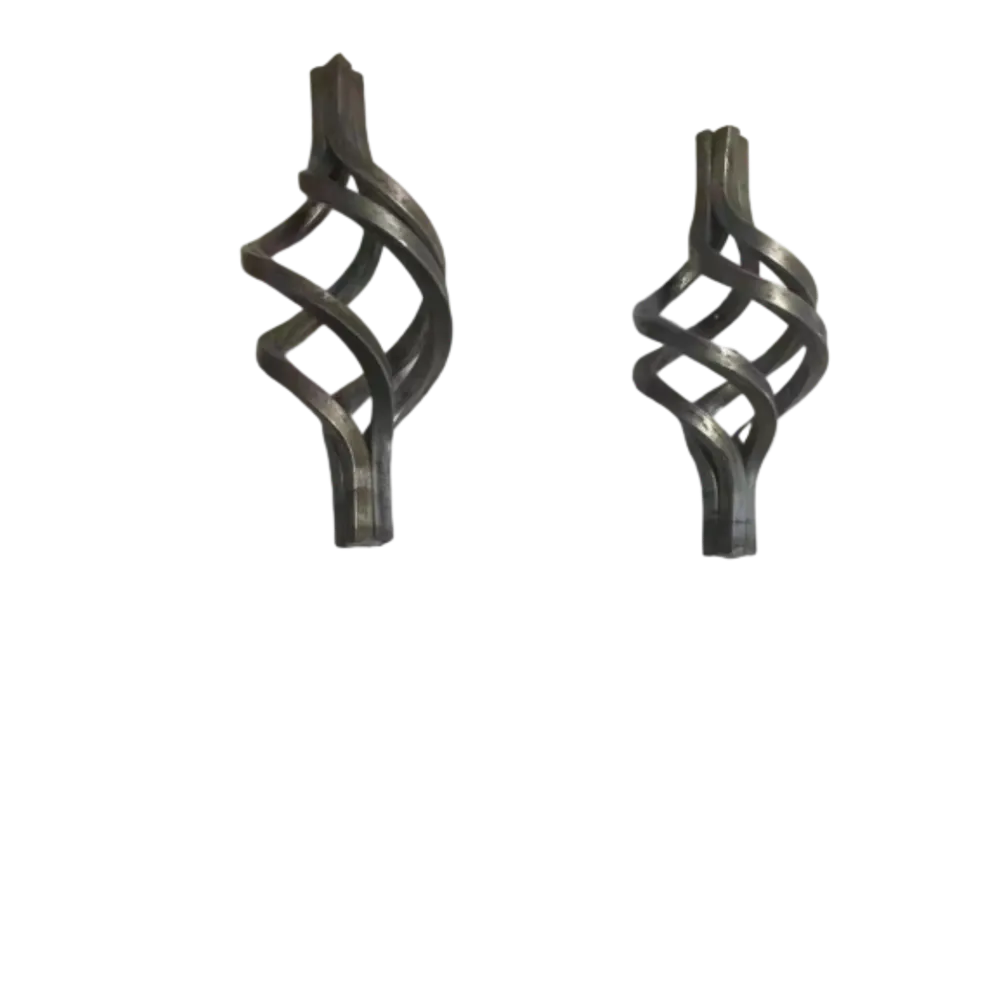

cast iron collar

The Significance of Cast Iron Collars in Modern Engineering

Cast iron collars are a remarkable testament to the ingenuity of material science and engineering. Known for their ability to combine strength, durability, and resistance to wear, these collars play a pivotal role in various applications across industries, from construction to manufacturing. This article explores the importance, applications, and innovative advancements surrounding cast iron collars.

Understanding Cast Iron Collars

Cast iron collars are cylindrical fittings made from cast iron, an alloy of iron, carbon, and silicon. This material is favored for its excellent castability, which allows for the production of complex shapes and sizes. The high carbon content in cast iron contributes to its hardness, making it an ideal choice for applications that require components to withstand significant pressure and stress.

Applications of Cast Iron Collars

Cast iron collars are utilized in numerous applications due to their robust properties. In construction, they are commonly used to reinforce beams and columns, providing structural integrity. These collars help in distributing loads evenly, ensuring that buildings and bridges can withstand the forces of nature and human activity.

In manufacturing, cast iron collars are used in machinery and equipment, acting as connection points between different components. They are essential in the assembly of pumps, compressors, and motors, where precision and durability are paramount. The ability of cast iron to resist wear and tear extends the lifespan of machinery, leading to decreased maintenance costs and improved efficiency.

Additionally, cast iron collars are popular in piping systems, especially in industries such as water supply and wastewater management. Their resistance to corrosion makes them ideal for use in environments that are constantly exposed to moisture. They also provide robust sealing capabilities, preventing leaks and ensuring that fluids are transported safely and efficiently.

Advantages of Cast Iron Collars

cast iron collar

The advantages of using cast iron collars are manifold. One of the primary benefits is their excellent strength-to-weight ratio. While they are heavier than some other materials, their durability ensures that they can handle heavy loads without deforming or breaking. This characteristic is indispensable in heavy-duty applications where reliability is crucial.

Another advantage is the cost-effectiveness of cast iron. The material is relatively low-cost compared to alternatives such as stainless steel or aluminum. When considering long-term usage and maintenance costs, cast iron collars present a financially prudent choice for many industries.

Furthermore, the ease of manufacturing cast iron makes it a versatile option for various designs and specifications. This adaptability means that engineers can create custom solutions tailored to specific needs, enhancing the functionality of the ultimate product.

Innovations and Future Prospects

As technology advances, so too does the manufacturing of cast iron collars. New techniques in casting and metallurgy are improving the properties of cast iron, resulting in even stronger and more resilient collars. Innovations such as the use of alloyed cast iron and the development of hybrid materials are paving the way for enhanced performance in challenging environments.

Additionally, the rise of sustainable manufacturing practices is influencing the production of cast iron collars. More manufacturers are adopting recycling methods that reduce waste and energy consumption, reflecting a growing commitment to environmental stewardship.

Conclusion

In conclusion, cast iron collars have established themselves as an essential component across various industries. Their strength, durability, and cost-effectiveness make them a preferred choice in numerous applications, from construction to manufacturing. As innovations continue to unfold, the future of cast iron collars looks promising, with advancements in material science and sustainable practices. Understanding the significance of these components not only highlights their utility in modern engineering but also underscores the enduring legacy of cast iron as a foundational material in our industrial landscape. Whether they are holding up structures or connecting vital machinery, cast iron collars will undoubtedly remain central to the progress and evolution of engineering and manufacturing for years to come.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters