Jan . 14, 2025 09:54

Back to list

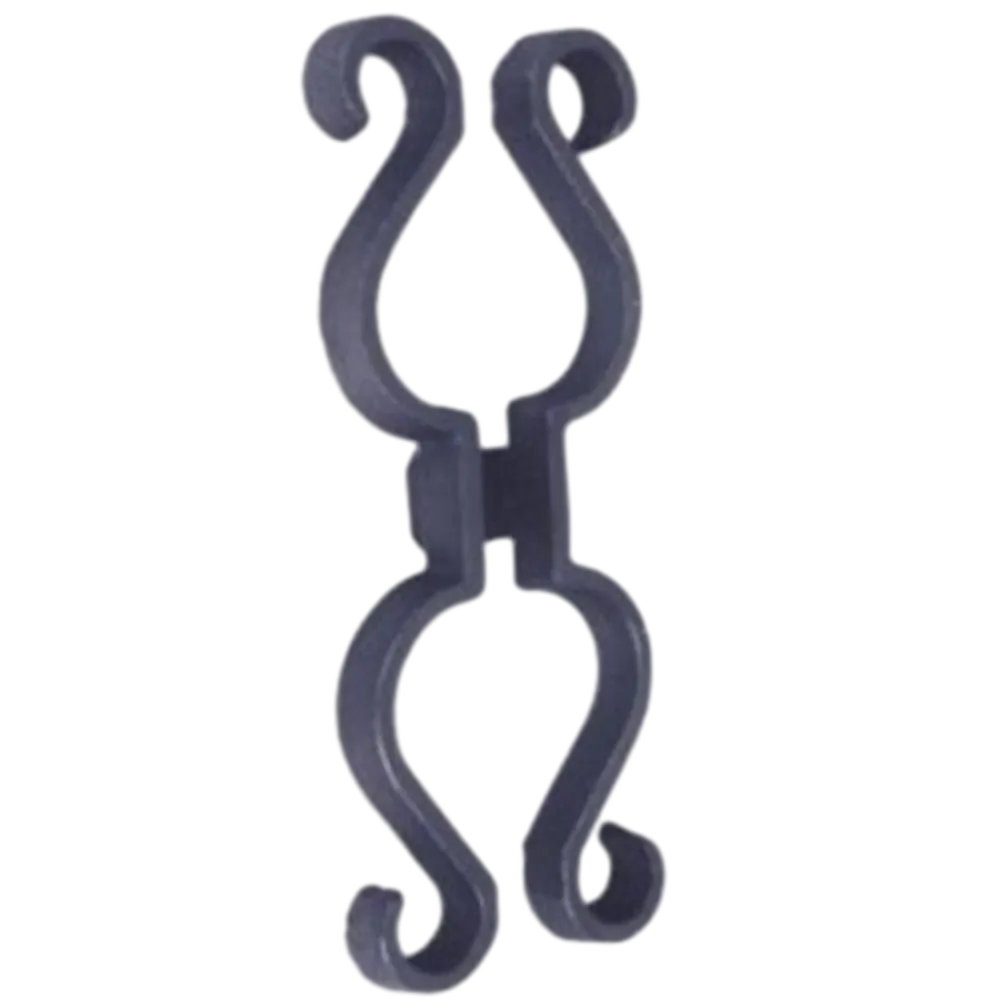

cast iron collars and bushes

In the rapidly evolving industrial landscape, the utilization of cast iron collars and bushes has garnered significant attention for their robust characteristics and application versatility. The synergy between traditional material strength and modern engineering precision gives these components an edge in numerous industrial applications.

Authoritativeness in the field of cast iron components is accrued through consistent quality delivery and innovation. Leading manufacturers often engage in continuous research and development to explore enhanced metallurgical compositions or forging techniques. By doing so, they foster advancements that not only meet contemporary requirements but also anticipate future industry demands. Collaborations with engineering bodies and institutions further cement their roles as authorities in cast iron collar and bush manufacturing. Trustworthiness hinges on the assurance of quality and consistency. Manufacturers deploy rigorous testing protocols tailored to each product's application, ensuring that every cast iron collar or bush leaving the facility meets the specified performance benchmarks. This commitment to quality is backed by certifications from recognized industry standards organizations, which reassures customers of the product's compliance and reliability. The testimonies from clients across diverse sectors underscore the reliability of cast iron collars and bushes. They recount experiences of reduced operational downtime, enhanced machine efficiency, and lower maintenance costs, attributing these benefits to the judicious employment of these components. Trust is further reinforced by the responsive service and technical support offered by manufacturers, addressing any operational challenges promptly and efficiently. In conclusion, the adoption of cast iron collars and bushes is a testament to their indispensable role in industrial applications. Their robustness, expertise-driven design, authoritative backing, and trustworthy performance align seamlessly with the demands of modern-day engineering challenges. Companies looking to enhance operational efficiency and machine longevity will find in these components a solution that is both time-tested and future-ready.

Authoritativeness in the field of cast iron components is accrued through consistent quality delivery and innovation. Leading manufacturers often engage in continuous research and development to explore enhanced metallurgical compositions or forging techniques. By doing so, they foster advancements that not only meet contemporary requirements but also anticipate future industry demands. Collaborations with engineering bodies and institutions further cement their roles as authorities in cast iron collar and bush manufacturing. Trustworthiness hinges on the assurance of quality and consistency. Manufacturers deploy rigorous testing protocols tailored to each product's application, ensuring that every cast iron collar or bush leaving the facility meets the specified performance benchmarks. This commitment to quality is backed by certifications from recognized industry standards organizations, which reassures customers of the product's compliance and reliability. The testimonies from clients across diverse sectors underscore the reliability of cast iron collars and bushes. They recount experiences of reduced operational downtime, enhanced machine efficiency, and lower maintenance costs, attributing these benefits to the judicious employment of these components. Trust is further reinforced by the responsive service and technical support offered by manufacturers, addressing any operational challenges promptly and efficiently. In conclusion, the adoption of cast iron collars and bushes is a testament to their indispensable role in industrial applications. Their robustness, expertise-driven design, authoritative backing, and trustworthy performance align seamlessly with the demands of modern-day engineering challenges. Companies looking to enhance operational efficiency and machine longevity will find in these components a solution that is both time-tested and future-ready.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters