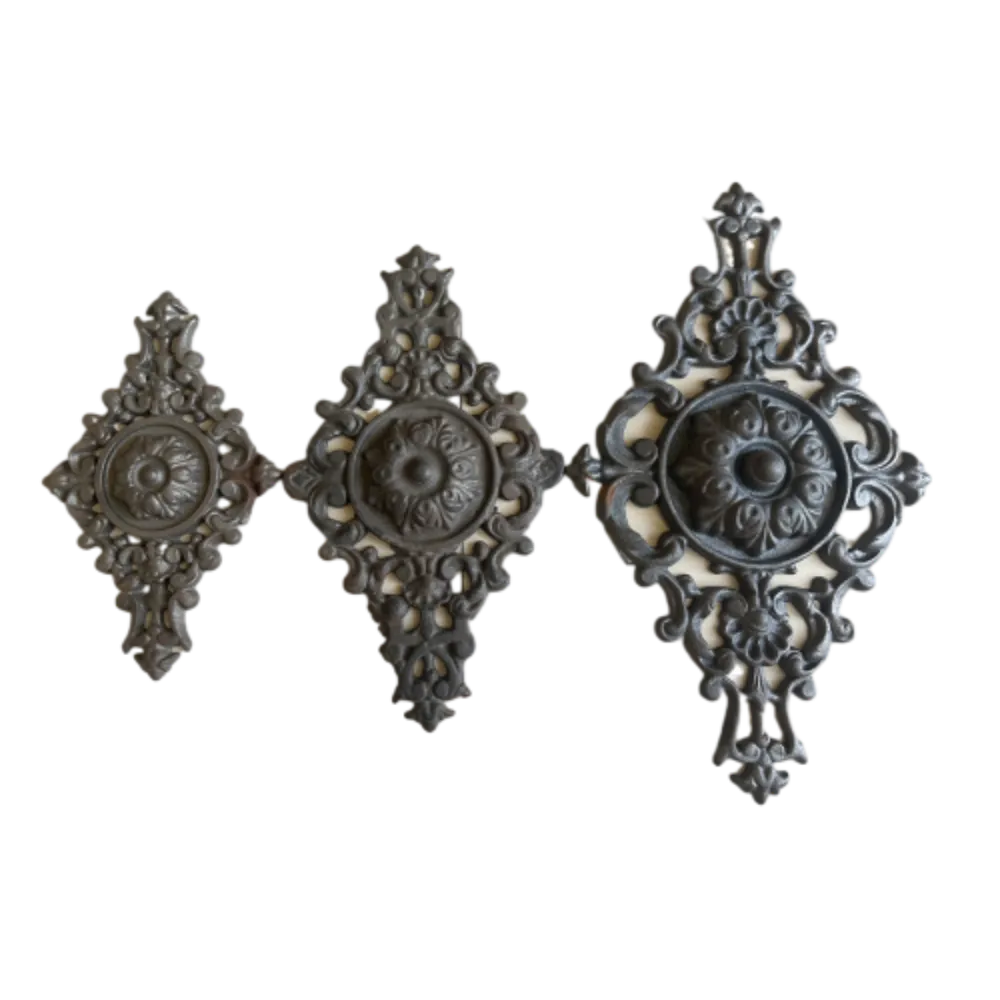

cast iron panel casting

The Art and Science of Cast Iron Panel Casting

Cast iron panel casting is a fascinating blend of artistry and engineering that has stood the test of time. Renowned for its durability and aesthetic appeal, cast iron has been used in various applications, from architectural elements to kitchen cookware. The process of casting iron panels involves several stages, each contributing to the final product's strength and beauty.

At the heart of cast iron panel casting is the melting of iron, which typically occurs in a furnace. The raw materials, including pig iron, scrap iron, and alloying agents, are carefully selected to meet specific mechanical and chemical properties. Once heated to around 1300 to 1500 degrees Celsius, the molten iron is poured into molds to create panels of various shapes and sizes. The design of these molds is crucial, as it determines not only the panel's form but also the surface texture and detail.

One of the primary advantages of cast iron is its ability to flow into intricate mold designs, capturing fine details that elevate the aesthetic value of the final product. This property makes it a popular choice for ornamental panels in architecture, such as balustrades, gates, and decorative screens. The versatility of cast iron allows for a range of finishes, from smooth and polished to rough and rustic, enabling designers to achieve a specific look for their projects.

cast iron panel casting

After the molten iron is poured into the molds, it goes through a cooling process. As the iron solidifies, it undergoes a transformation in its microstructure, resulting in the characteristic strength and toughness of cast iron. The cooling rate can be controlled to create different grades of cast iron, such as gray iron, ductile iron, and white iron, each with unique properties suited for specific applications.

Once cooled, the cast iron panels are removed from the molds and undergo various finishing processes. This may include machining to achieve precise dimensions, surface treatment to enhance corrosion resistance, and painting or coating for aesthetic purposes. These finishing touches not only improve the panel's visual appeal but also extend its lifespan, making it a reliable choice for both indoor and outdoor applications.

In conclusion, cast iron panel casting is a sophisticated process that combines traditional craftsmanship with modern technology. By understanding the intricacies of material selection, mold design, and finishing techniques, manufacturers can produce cast iron panels that are not only functional but also visually stunning. As demand for durable and aesthetically pleasing building materials continues to grow, the art of cast iron casting remains relevant and celebrated, a testament to its enduring legacy in design and engineering.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters