Jan . 10, 2025 12:20

Back to list

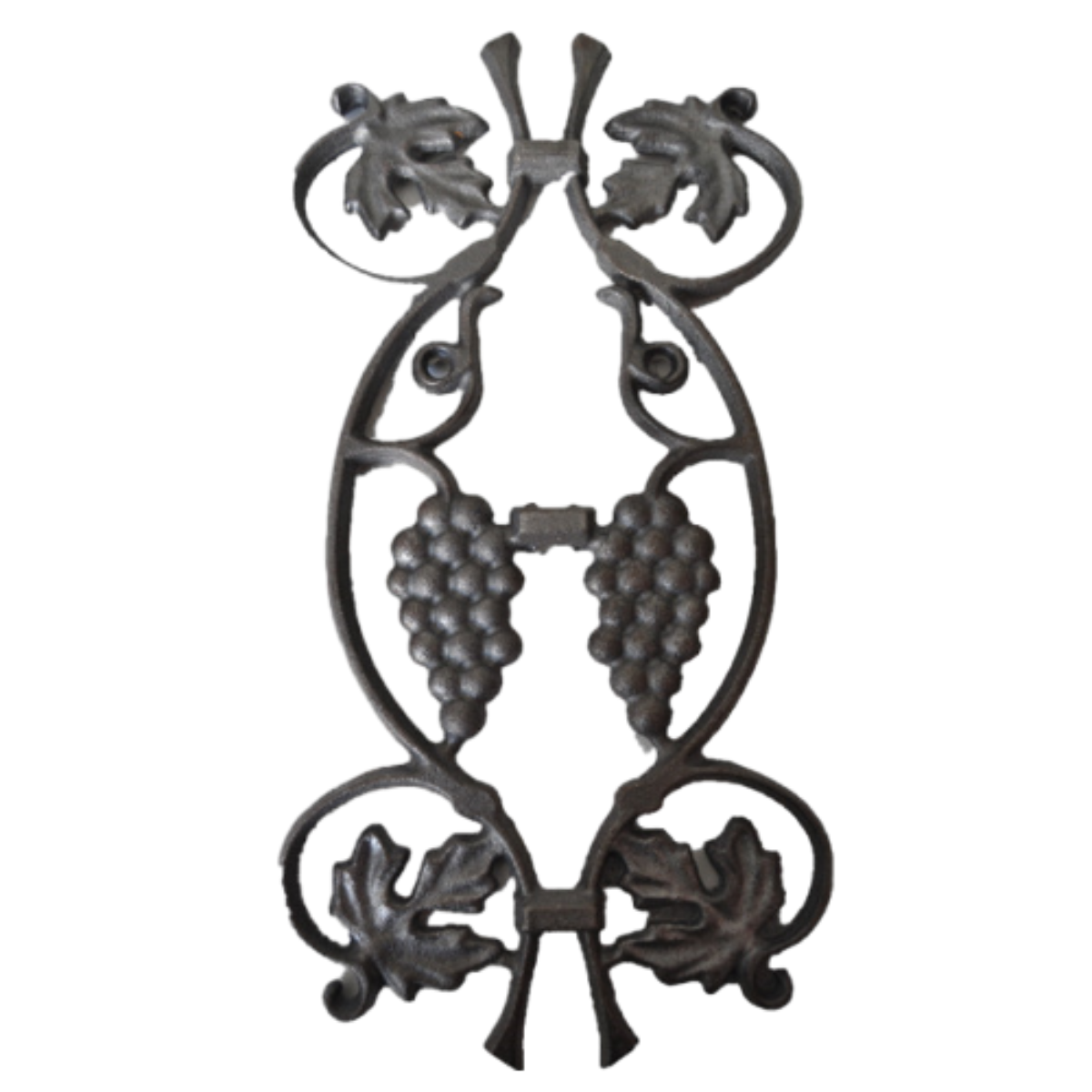

cast iron panel casting

Choosing the right material for manufacturing and construction projects is pivotal in ensuring product durability, performance, and quality. Among the numerous materials available, cast iron casting stands out due to its unique properties and benefits. With a legacy dating back centuries, cast iron casting continues to be a preferred choice for many industries worldwide.

Trustworthiness is another critical factor when considering cast iron casting. The longevity and reliability of cast iron components have been repeatedly proven in numerous applications across various sectors, from automotive to agricultural equipment. Manufacturers often provide extensive warranties and after-sale support, ensuring clients receive not only superior products but also long-standing peace of mind. Environmental considerations also favor cast iron casting. The recycling of scrap iron significantly contributes to sustainable manufacturing processes, reducing waste and minimizing environmental impact. Moreover, the durability of cast iron products translates to less frequent replacements, further promoting sustainability by extending the life cycle of components. In sectors where precision, durability, and reliability are non-negotiable, such as automotive components, hydraulic machinery, and heavy construction equipment, cast iron casting continues to be the material of choice. These industries rely on the material’s robustness and capacity to withstand significant stress and heavy loads without compromising on performance or safety. In conclusion, cast iron casting remains an unparalleled choice for industries requiring materials with high wear resistance, excellent machinability, and vibrational damping characteristics. Its enduring presence in the market not only highlights its superior attributes but also reflects the continuous advancements in casting technology and techniques. As industries evolve, the adaptability and resilience of cast iron casting will undoubtedly support their growth, offering solutions that blend traditional material strength with modern technological insights.

Trustworthiness is another critical factor when considering cast iron casting. The longevity and reliability of cast iron components have been repeatedly proven in numerous applications across various sectors, from automotive to agricultural equipment. Manufacturers often provide extensive warranties and after-sale support, ensuring clients receive not only superior products but also long-standing peace of mind. Environmental considerations also favor cast iron casting. The recycling of scrap iron significantly contributes to sustainable manufacturing processes, reducing waste and minimizing environmental impact. Moreover, the durability of cast iron products translates to less frequent replacements, further promoting sustainability by extending the life cycle of components. In sectors where precision, durability, and reliability are non-negotiable, such as automotive components, hydraulic machinery, and heavy construction equipment, cast iron casting continues to be the material of choice. These industries rely on the material’s robustness and capacity to withstand significant stress and heavy loads without compromising on performance or safety. In conclusion, cast iron casting remains an unparalleled choice for industries requiring materials with high wear resistance, excellent machinability, and vibrational damping characteristics. Its enduring presence in the market not only highlights its superior attributes but also reflects the continuous advancements in casting technology and techniques. As industries evolve, the adaptability and resilience of cast iron casting will undoubtedly support their growth, offering solutions that blend traditional material strength with modern technological insights.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters