Durable Cast Iron Picket Castings for Fencing and Decorative Purposes

Exploring the World of Cast Iron Picket Castings

Cast iron has been a cornerstone in the world of metalworking and manufacturing for centuries. Its unique properties—strength, durability, and resistance to wear—have made it an ideal material for various applications. Among the many products crafted from cast iron, picket castings stand out for their aesthetic appeal and functional attributes. This article delves into cast iron picket castings, exploring their significance, manufacturing process, applications, and benefits.

Understanding Cast Iron Picket Castings

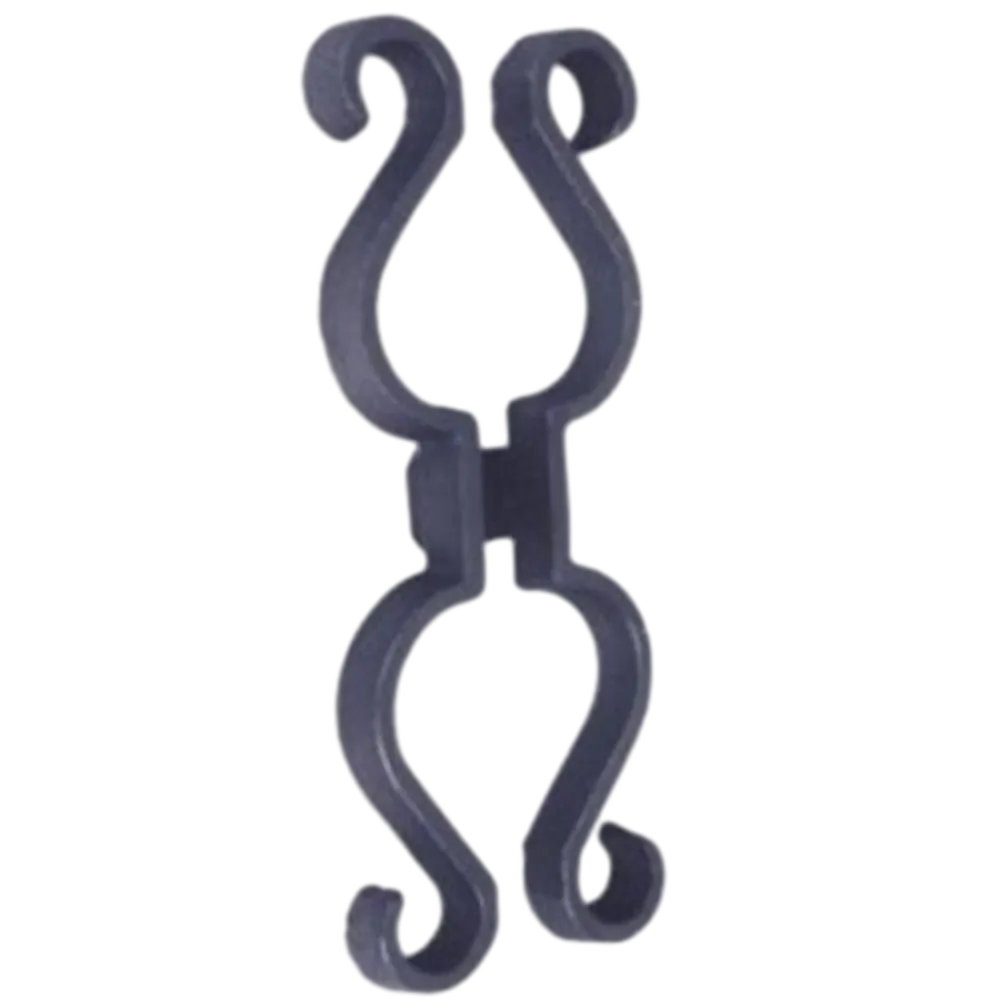

Cast iron picket castings are ornamental elements typically used in fencing, gates, and architectural features. These castings are characterized by their intricate designs and robust construction, making them a popular choice for both residential and commercial properties. They serve not only as functional barriers but also as decorative enhancements that elevate the visual appeal of outdoor spaces.

The Manufacturing Process

The production of cast iron picket castings involves several steps, starting with the preparation of the mold. Typically, molds are created from sand or metal and are designed to accommodate the specific shapes of the pickets. The casting process begins with the melting of iron in a furnace. The molten iron is then poured into the prepared molds and allowed to cool. This cooling process solidifies the iron into the desired shape.

Once the castings have cooled, they undergo finishing processes such as grinding, sandblasting, or coating to enhance their appearance and corrosion resistance. The final product may also receive a protective painted finish, adding an extra layer of durability and aesthetic appeal.

Applications of Cast Iron Picket Castings

The applications of cast iron picket castings are extensive

. They are most commonly used in fencing and railing systems, providing security while ensuring visibility. These elements can be found in gardens, parks, and residential properties, where they contribute to the overall design of the landscape.cast iron picket castings

In addition to their use in fencing, cast iron picket castings are often employed in creating gates, balconies, and other architectural features. Their inherent strength allows them to withstand the elements, making them suitable for exterior applications. Furthermore, the variety of designs available caters to different architectural styles, from classical to modern, ensuring versatility in design.

Benefits of Cast Iron Picket Castings

There are numerous benefits to utilizing cast iron picket castings. One of the primary advantages is their durability; cast iron can withstand harsh weather conditions, including rain, snow, and sunlight, without deteriorating. This longevity translates to reduced maintenance costs and a longer lifespan for the installations.

Another significant benefit is their aesthetic value. The intricate designs and polished finishes of cast iron picket castings can enhance the beauty of any property, adding a touch of elegance and sophistication. Moreover, these castings can be customized to match specific design preferences, further enhancing their appeal.

Environmental Considerations

In today’s world, sustainability is a vital consideration in manufacturing. Cast iron is often made from recycled materials, making cast iron picket castings an environmentally friendly choice. Furthermore, the longevity of cast iron products contributes to sustainability by reducing the need for frequent replacements.

Conclusion

In summary, cast iron picket castings are a blend of beauty and practicality. Their robust nature, combined with elegant designs, makes them a favored choice for enhancing both security and aesthetics in various settings. As the demand for durable and environmentally friendly materials continues to grow, cast iron picket castings remain a relevant and timeless option for architects, builders, and homeowners alike. Its historical significance and continued use in modern design ensure that cast iron will remain an essential material for years to come.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters