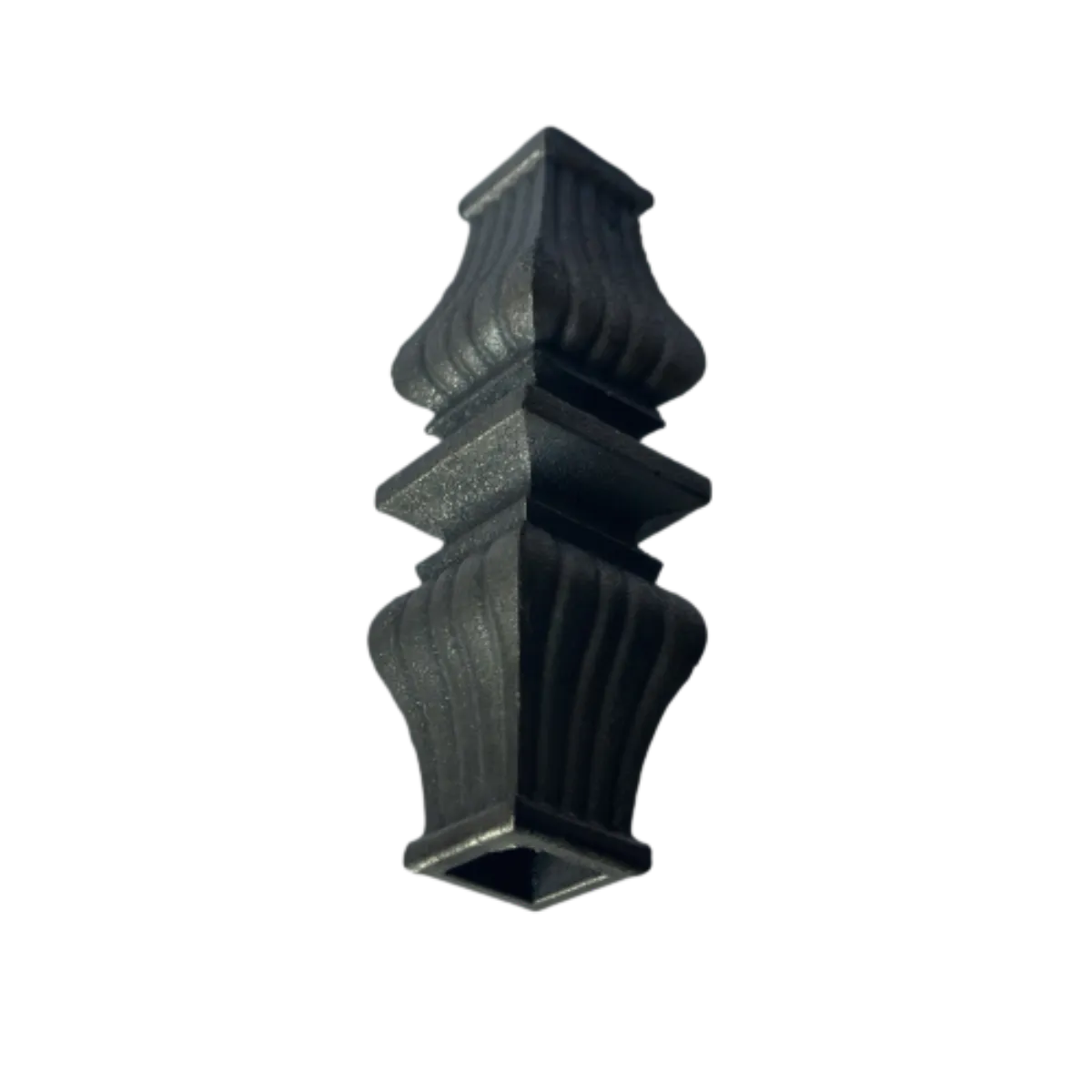

Durable Cast Iron Railheads for Long-lasting Performance and Safety in Rail Applications

The Evolution and Importance of Cast Iron Railheads

Cast iron railheads have played a crucial role in the development of railway infrastructure throughout history. These meticulously crafted components serve as the interface between the rail tracks and the rolling stock, ensuring smooth and safe movements for trains. The evolution of cast iron railheads reflects advancements in both material science and engineering techniques.

Historically, cast iron railheads emerged during the early days of rail transportation in the early 19th century. Iron was favored for its strength and durability, and casting methods allowed for mass production of rail components. These railheads, with their distinctive shapes, were designed to withstand the heavy loads of locomotives and carriages, providing stability and safety on the tracks. Moreover, their relatively low cost made them an economical choice for railway companies looking to expand their networks.

As technology progressed, the design and manufacturing processes of cast iron railheads improved. The introduction of alloying elements such as carbon and silicon enhanced the properties of cast iron, offering better hardness and wear resistance. This led to longer-lasting railheads that required less frequent replacements, ultimately reducing maintenance costs for railway operators. Innovations in casting techniques, including sand casting and precision molding, further allowed for the production of railheads with tighter tolerances and better surface finishes.

cast iron railheads

In modern railway applications, while many rail systems have transitioned to steel or composite materials for railheads, cast iron continues to hold a significant place in certain contexts. Its excellent damping characteristics make it ideal for specific high-speed rail applications, providing a quieter and smoother ride. Additionally, cast iron railheads are still used in heritage and light rail systems, where historical accuracy and aesthetic appeal are paramount.

Furthermore, as sustainability gains prominence in the industrial sector, recycling of cast iron railheads has become an essential practice. End-of-life rail components can be melted down and repurposed, minimizing waste and reducing the environmental impact associated with new material production.

In conclusion, cast iron railheads embody a rich history of engineering innovation, contributing to the safe and efficient movement of trains. Their evolution from simple components to sophisticated designs illustrates the progress of material science, and their continued use highlights their enduring relevance in contemporary railway systems. The balance of tradition and modernity makes cast iron railheads a fascinating aspect of railway engineering.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters