Sliding Door Roller Bearings for Smooth Operation and Durability

Understanding Door Roller Bearings A Comprehensive Overview

Door roller bearings play a pivotal role in the smooth functioning of various types of doors, particularly sliding and bi-fold doors. These components facilitate easy movement, reduce friction, and enhance durability, ensuring that doors operate seamlessly over time. In this article, we will explore the workings of door roller bearings, their types, applications, and maintenance tips to maximize their performance.

What Are Door Roller Bearings?

Door roller bearings are specialized mechanisms that allow doors to glide or roll open and closed with minimal resistance. Typically made of high-quality materials such as stainless steel or nylon, these bearings consist of balls or rollers that rotate around a shaft, significantly reducing friction between the door and the track. This design not only aids in smooth operation but also prolongs the lifespan of the door system.

Types of Door Roller Bearings

There are several types of door roller bearings, each suited for specific applications

1. Single Wheel Rollers Commonly used for lightweight doors, single wheel rollers are compact and provide basic functionality. They are usually found in interior sliding doors.

2. Double Wheel Rollers These consist of two wheels per bearing, offering enhanced stability and support for heavier doors. They are often used in exterior sliding doors and larger bi-fold systems.

3. Ball Bearings Utilizing small steel balls to minimize friction, ball bearings provide ultra-smooth movement and are commonly used in high-end sliding door systems that require frequent use.

4. Nylon Rollers These are made from durable nylon material, which not only provides smooth operation but also noise reduction. They are often chosen for their resistance to wear and corrosion, making them suitable for both indoor and outdoor applications.

Applications of Door Roller Bearings

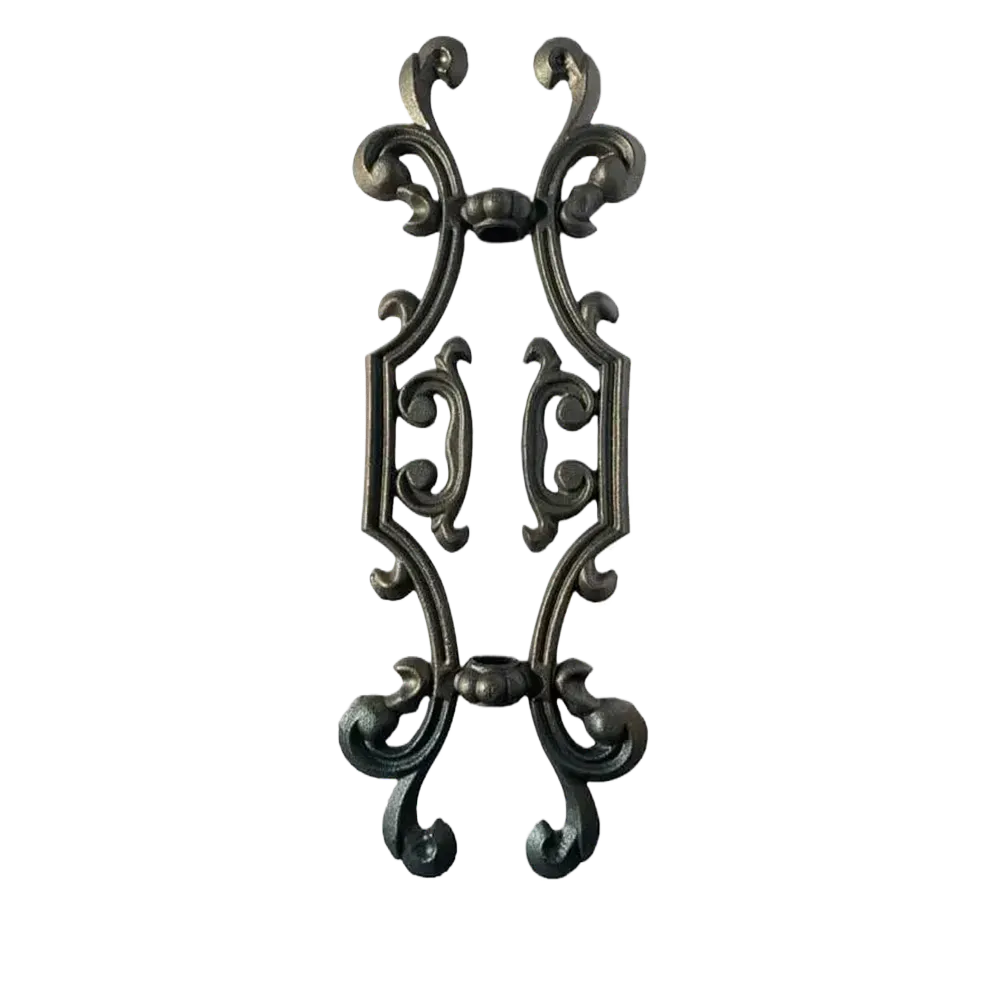

door roller bearing

Door roller bearings are versatile and can be found in various settings, including

- Residential Homes Used in sliding patio doors, closets, and pantry doors, roller bearings ensure that these doors operate effortlessly. - Commercial Buildings In retail spaces, office partitions, and conference rooms, roller bearings are crucial for movable walls and sliding glass doors, enabling flexible use of space. - Industrial Applications Heavy-duty roller bearings are essential in warehouses and factories for loading docks and large doors that require robust support and durability.

Maintenance Tips for Door Roller Bearings

To ensure the longevity and efficiency of door roller bearings, regular maintenance is essential. Here are a few tips

1. Keep Tracks Clean Dirt and debris can accumulate in the tracks, hindering the movement of rollers. Regularly clean the track with a damp cloth and a gentle cleaner to keep it free from obstacles.

2. Lubrication Apply a suitable lubricating oil to the bearings periodically. This reduces friction and prevents wear. However, avoid over-lubrication, as excess lubricant can attract dust and grit.

3. Check for Damage Regularly inspect the rollers for signs of wear and tear. Look for cracks or chips in the wheels and replace damaged bearings immediately to prevent further issues.

4. Address Misalignment If a door becomes difficult to glide, check if it’s misaligned. Adjust the door and rollers as needed to ensure proper alignment within the track.

Conclusion

Door roller bearings are essential components that contribute significantly to the functionality of sliding and bi-fold doors in both residential and commercial settings. By understanding their types, applications, and maintenance, you can ensure that these systems operate smoothly and last for years. Investing time in proper care and maintenance will not only enhance the user experience but also save on potential repair or replacement costs in the future. In conclusion, door roller bearings are small yet mighty elements in the landscape of door mechanics, worthy of attention and care.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters