Durable Cast Iron Panels | AI-Enhanced Designs

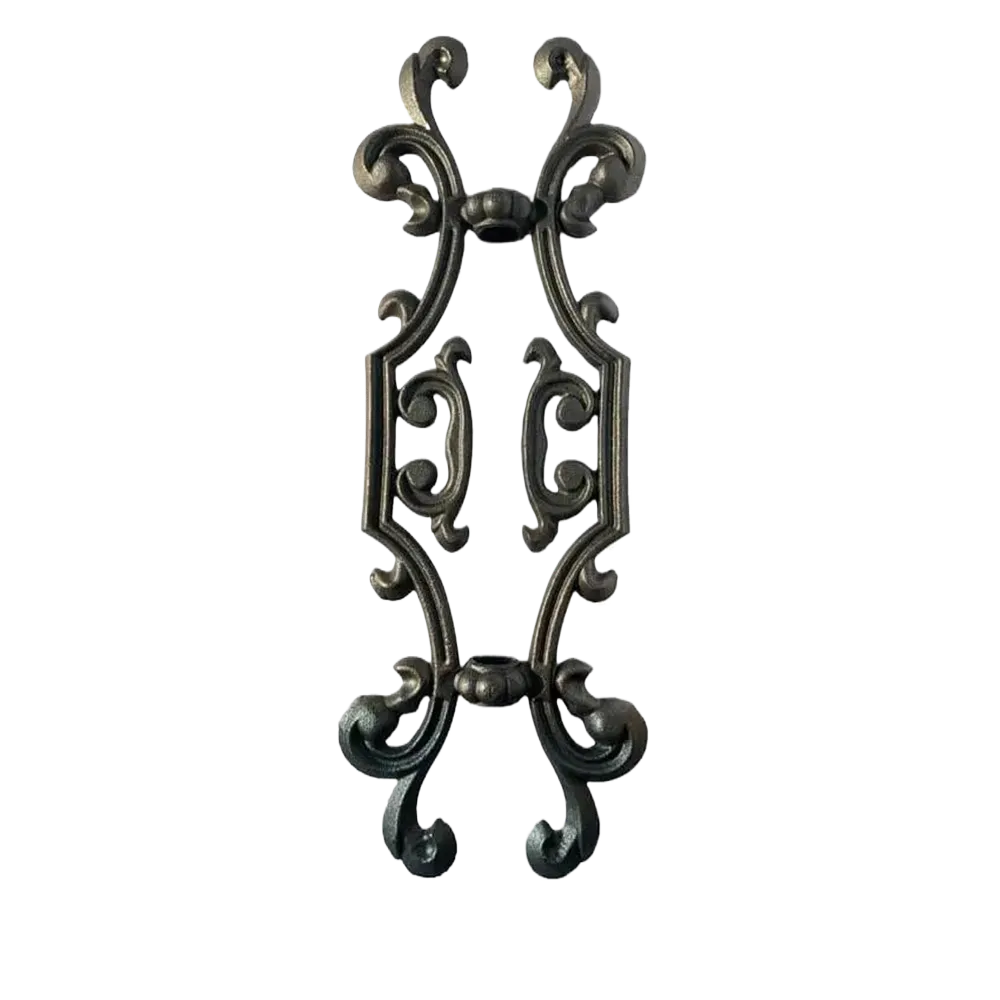

As architectural design demands blend both durability and aesthetics, cast iron panels have re-emerged as an industry standard for modern infrastructure, restoration, and premium fencing solutions. This guide explores the latest trends, technical details, manufacturing processes, and real-life application cases regarding cast iron panels, with deep dives into product certifications, specifications, and customization for the most demanding projects.

Industry Trends: The Rise of Cast Iron Panels in Modern Applications

Global demand for cast iron fence panels and cast iron railing panels has seen steady growth, particularly in premium public infrastructure, commercial buildings, and historical renovation. According to Statista, the worldwide decorative iron components market is projected to grow at a CAGR of 5.6% between 2023 and 2028, driven by features such as anti-corrosion technology, robust casting processes, and innovative designs.

- Segment growth: Urban landscaping, premium real estate, and heritage restoration account for over 67% of demand (Global Iron Decorative Materials Report, 2023).

- Technology integration: Adoption of CNC machining, anti-rust coatings, and custom design capabilities transforming traditional decorative cast iron manufacturing.

- Regulatory trends: Increasing compliance with international standards (ISO 9001, ANSI, etc.) for quality and sustainability in decorative components.

Technical Specifications & Parameter Table

Below are the key parameters that define premium cast iron panels, reflecting their performance in both structural and decorative settings.

| Specification | Decorative Iron Panels | Common Steel Panels | Aluminum Decorative Panels |

|---|---|---|---|

| Material Grade | HT200/HT250 Grey Cast Iron | Q235/Q345 Low-Carbon Steel | 6063-T5 Aluminum Alloy |

| Tensile Strength | 200–250 MPa | 375–470 MPa | 140–185 MPa |

| Yield Strength | 130–170 MPa | 235–355 MPa | – |

| Surface Treatment | Powder Coating, Hot-dip Galvanizing | Galvanized, Painted | Anodized, Painted |

| Corrosion Resistance | Excellent (Salt Spray >500h) | Moderate | Excellent |

| Design Flexibility | Highly Ornate, Customizable | Medium | Ornate, Lightweight |

| Approximate Lifespan | 50+ Years | 20–35 Years | 20–35 Years |

| Applicable Standards | ISO 9001, ANSI/NAAMM | ASTM A36, ISO 9001 | ASTM B221 |

- HT200/HT250: High tensile grey cast iron, excels in vibration damping and corrosion resistance.

- Powder coating: Extends service life and gives vibrant, long-lasting decorative appeal.

- ISO 9001: Ensures manufacturing and quality consistency.

Manufacturing Process Deep Dive: How Decorative Iron Panels Are Made

Decorative Iron Panels from TJJ Iron Casting are crafted through meticulous stages, ensuring both outstanding decorative flair and robust structural integrity. The diagram below outlines the typical workflow, from raw material selection to final quality inspection and delivery.

HT200/250 Iron, 100% tested

Induction Furnace

Sand/Die Casting

Precision cutting/Ornamental Routing

Powder Coating/Galvanizing

ISO 9001, Salt Spray, Dimensional

Protective Crating & Tracking

Note: Each stage is defined by stringent test protocols (Dimensional, Tensile, and GB/T6892 for panel flatness) to ensure that each decorative cast iron component surpasses both international and custom project standards.

Factory Comparison: Decorative Iron Panels vs. Leading Industry Manufacturers

Selecting the right supplier is critical for project success. We compared the Decorative Iron Panels from TJJ Iron Casting with other mainstream brands:

| Feature | Decorative Iron Panels (TJJ Iron Casting) |

Brand A | Brand B |

|---|---|---|---|

| Material Purity | 98.6% Fe, Low S/P Content | 95–97% Fe | 96–98% Fe |

| Panel Thickness | 8–25 mm (customizable) | 4–18 mm | 6–20 mm |

| Surface Coating | Trilayer Powder + Zn Dip | Dual-layer Paint | Powder Coating |

| Supported Designs | 300+ Deco Patterns | 80–120 Patterns | 60–100 Patterns |

| Certifications | ISO 9001, ANSI/NAAMM, SGS | ISO 9001 | CE |

| ISO Salt Spray Hours | >500 Hrs (ASTM B117) | 200–350 Hrs | 200–400 Hrs |

| Lifespan Estimate | 50+ Years | 30–35 Years | 32–40 Years |

- SGS Testing: Third-party chemical analysis and salt spray testing ensure the reliability of decorative railing panels for premium projects.

- ANSI/NAAMM: North American architectural metal standard compliance, critical for public and municipal installations.

Customization & Project Delivery Solutions

All decorative cast iron solutions are fully customizable to client sketches or CAD files. Services include pattern development, anti-corrosive coatings (PPG powder, Zn hot-dip), color matching (RAL & Pantone), and complete supply/installation packages for:

- Urban fencing and parks (anti-vandal, graffiti-resistant surface)

- Heritage/monument restoration (original pattern replication)

- Oil/petrochemical, hydropower—industrial handrails

- Luxury residences—bespoke decorative railing panels for stairs and balconies

Minimum order: 50 meters or 10 panels. Typical lead time: 30–40 days for custom molds, 15–18 days for standard designs.

Warranty: 5–10 years anti-corrosion (depending on spec). Support: Drawings, 3D renders, installation guides, and global shipping available.

Case Studies & Application Success

Historic Museum, France (2021): Precision custom panels (CNC + hand finishing) replaced 19th-century ironwork, color matched to original patinas, exceeding the client’s expectations for authenticity and strength.

Industrial Site, UAE (2024): Heavy-duty cast iron railing panels for chemical plant walkways, achieving 8x longer salt-spray resistance compared to prior stainless options.

Customer Feedback: “TJJ Iron’s panels met all our specs for EN1991 loading and anti-corrosion—our site’s first zero-maintenance cycle in 18 years.” — Thomas H., Site Manager, Bostwick Engineering

FAQ: Expert FAQ on Cast Iron Panel Projects

Delivery Terms, Certification & Customer Support

- Delivery: Standard design panels ship in 15–18 working days; bespoke orders require 30–40 days due to mold development.

- Shipping: Sea/air freight with custom crating and global tracking; express samples available on request.

- Certifications: ISO 9001, SGS chemical/physical analysis, ANSI/NAAMM MBG 531, and EN1090 as requested.

- Warranty: 5–10 years (subject to coating spec and installation scope).

- Support: Technical drawings, installation manuals, real-time video QA, and 7x24 customer support.

Conclusion & Authoritative Industry References

The evolution of cast iron panels and decorative iron components underscores their value not just as ornamental features but as enduring, structurally crucial assets for diverse sectors. Whether for municipal, industrial, or architectural needs, the technical edge, rigorous certification, and customization offered by Decorative Iron Panels make them a top-tier solution worldwide.

- Statista, “Global Decorative Iron Panel Market Report 2023–2028” [statista.com]

- NAAMM Metal Bar Grating Committee, “ANSI/NAAMM MBG 531” [naamm.org]

- SGS, “Corrosion Testing and Certification for Architectural Metalwork” [sgs.com]

- Hardware Forums, “Experiences with Cast Iron Fence Panel Durability” [hardwareforums.com]

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters