Finding Reliable Suppliers for High-Quality Iron Products and Materials in Your Area

The Importance of Selecting the Right Iron Supplier

Iron, one of the most essential materials used in various industries, plays a critical role in construction, manufacturing, and even in the creation of consumer goods. As the demand for iron continues to rise globally, selecting the right iron supplier becomes increasingly vital for businesses looking to ensure quality, reliability, and cost-effectiveness in their supply chains.

Understanding the Role of Iron Suppliers

Iron suppliers provide the raw material required for numerous applications, ranging from building infrastructure to producing machinery and tools. Their role extends beyond merely supplying iron; they are responsible for ensuring that the metal meets certain quality standards and specifications required by different industries. The choice of an iron supplier can profoundly affect the overall production process, product durability, and the efficiency of operations.

Factors to Consider When Choosing an Iron Supplier

1. Quality of Material The foremost criterion for selecting an iron supplier is the quality of iron they provide. Poor quality iron can lead to product failures, safety hazards, and considerable financial loss. Reputable suppliers will conduct rigorous testing and provide certification for their products, ensuring compliance with industry standards.

2. Cost Competitiveness While quality is crucial, the cost remains an essential factor in the supplier selection process. Businesses must find a balance between quality and price. It's vital to conduct market research, compare quotes, and evaluate the overall value offered by different suppliers. Beware of suppliers offering significantly lower prices, as this may indicate compromised quality.

3. Timeliness of Delivery The reliability of delivery schedules is another critical aspect of becoming a successful partner for any business. Delayed supplies can halt production lines and lead to missed deadlines. Working with suppliers who have a solid track record for timely deliveries is paramount for maintaining operational efficiency.

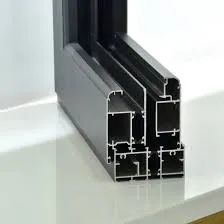

iron supplier

4. Customer Service A responsive and knowledgeable customer service team is essential when choosing an iron supplier. Issues may arise during the procurement or delivery process, and having a supplier that prioritizes customer satisfaction can significantly enhance your business operations.

5. Reputation and Experience Investigating a supplier’s reputation in the market can provide insights into their reliability and service quality. Suppliers with extensive experience in the industry are generally more equipped to handle challenges and provide solutions promptly.

6. Sustainability Practices As companies increasingly prioritize sustainability, it is wise to consider suppliers who adhere to eco-friendly practices. Sourcing iron from suppliers that engage in responsible extraction and production processes not only aligns with corporate social responsibility goals but also improves the overall sustainability profile of a business.

Building Long-Term Relationships

Establishing a long-term relationship with a reliable iron supplier can yield significant benefits in terms of pricing, priority in deliveries, and access to premium products. Collaborative partnerships also foster open lines of communication, making it easier to address issues, forecast needs, and adapt to changes in demand.

Conclusion

In an increasingly competitive market, businesses must acknowledge the crucial role of choosing the right iron supplier. The decision impacts not only the immediate procurement process but also the overall operational efficiency and success of an organization. By focusing on quality, cost, reliability, and sustainable practices, businesses can forge partnerships that not only meet their current needs but also support their future growth. Hence, investing time and resources in selecting the ideal iron supplier can lead to lasting benefits that resonate across all facets of a company’s operations.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters