Jan . 26, 2025 03:15

Back to list

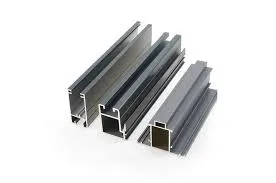

Sliding Door Rollers

Heavy duty door rollers play a critical role in ensuring the smooth operation and longevity of industrial doors. These components are essential for businesses that rely on robust entry systems, offering both functionality and reliability. Crafted from durable materials designed to withstand substantial weight and frequent use, heavy duty door rollers are indispensable in various commercial and industrial settings.

Establishing authoritativeness in the context of heavy duty door rollers involves understanding the pivotal players in the market and the technological advancements they bring. Leading manufacturers constantly innovate by integrating features such as self-lubricating mechanisms and specialized seals, which enhance the life and performance of their products. Recognizing these advancements allows businesses to make informed decisions about which products will best suit their operational needs. Trustworthiness is another critical attribute when discussing heavy duty door rollers. It is paramount for businesses to source these components from reputable suppliers who adhere to industry standards and warranties. Relying on established manufacturers not only provides peace of mind but also ensures that the products have been rigorously tested and meet stringent quality requirements. This reliability mitigates risks associated with downtime and operational failures. A practical example underscores the importance of trusted heavy duty door rollers a leading auto manufacturing plant improved its production line efficiency by replacing standard rollers with premium-grade heavy duty versions. This strategic move eliminated frequent breakdowns, enhancing workflow continuity. Their case study serves as a compelling testament to the value of choosing quality over cost-cutting, reassuring other businesses considering similar investments. In conclusion, the selection of heavy duty door rollers is a decision that should be grounded in solid understanding and evaluation of the product features and benefits. Combining real-world experience with insights from industry expertise, businesses can identify the best components that satisfy their specific operational demands. Judicious choices in heavy duty door rollers not only translate to financial savings but also reinforce the structural integrity and dependability of critical business infrastructures.

Establishing authoritativeness in the context of heavy duty door rollers involves understanding the pivotal players in the market and the technological advancements they bring. Leading manufacturers constantly innovate by integrating features such as self-lubricating mechanisms and specialized seals, which enhance the life and performance of their products. Recognizing these advancements allows businesses to make informed decisions about which products will best suit their operational needs. Trustworthiness is another critical attribute when discussing heavy duty door rollers. It is paramount for businesses to source these components from reputable suppliers who adhere to industry standards and warranties. Relying on established manufacturers not only provides peace of mind but also ensures that the products have been rigorously tested and meet stringent quality requirements. This reliability mitigates risks associated with downtime and operational failures. A practical example underscores the importance of trusted heavy duty door rollers a leading auto manufacturing plant improved its production line efficiency by replacing standard rollers with premium-grade heavy duty versions. This strategic move eliminated frequent breakdowns, enhancing workflow continuity. Their case study serves as a compelling testament to the value of choosing quality over cost-cutting, reassuring other businesses considering similar investments. In conclusion, the selection of heavy duty door rollers is a decision that should be grounded in solid understanding and evaluation of the product features and benefits. Combining real-world experience with insights from industry expertise, businesses can identify the best components that satisfy their specific operational demands. Judicious choices in heavy duty door rollers not only translate to financial savings but also reinforce the structural integrity and dependability of critical business infrastructures.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters