Cast Iron Alloys and Their Applications in Modern Engineering

Understanding Cast Iron Properties, Applications, and Benefits

Cast iron, a versatile material with a rich history, has been a cornerstone in various industries since ancient times. Its unique composition, primarily comprised of iron, carbon, and silicon, grants it specific characteristics that make it an ideal choice for numerous applications. This article delves into the properties, applications, and benefits of cast iron, shedding light on its enduring significance in modern manufacturing and construction.

Properties of Cast Iron

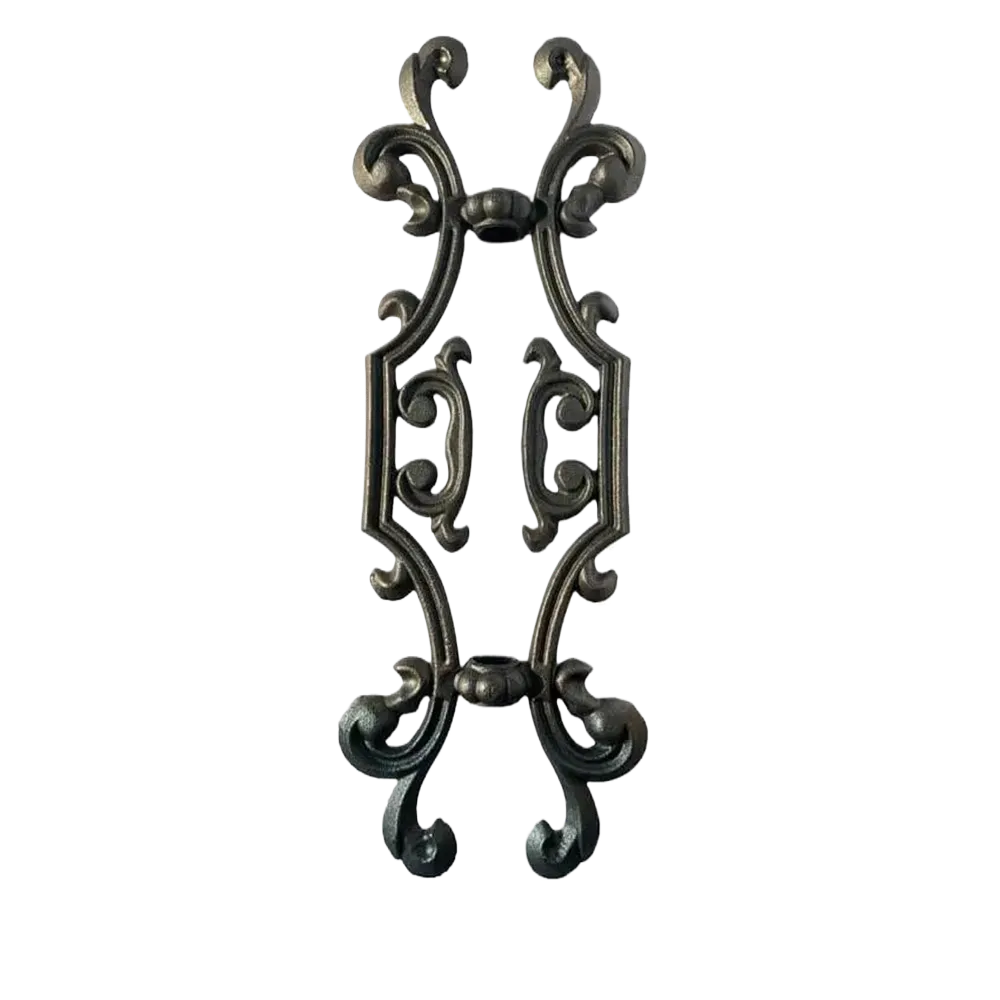

Cast iron is known for its excellent castability, allowing it to be poured into intricate molds and retain fine details. This property is attributed to its relatively low melting point, which ranges from 1,200 to 1,500 degrees Celsius, depending on the type of cast iron. One of the most notable features of cast iron is its ability to absorb vibrations, making it suitable for products that need to dampen noise and vibrations, such as engine blocks and cooking pots.

The material is generally characterized by its brittleness when compared to steel, meaning it can fracture under high stress rather than deform. However, its high compressive strength and wear resistance compensate for this brittleness, making it suitable for applications where durability is paramount. Additionally, cast iron can be classified into different types, including gray cast iron, ductile iron, white cast iron, and malleable iron, each possessing unique properties that cater to specific needs.

Applications of Cast Iron

The applications of cast iron are vast and varied. In the construction industry, cast iron is frequently used for structural components and architectural elements, such as columns, beams, and decorative facades. Its strength and durability make it an ideal material for heavy-duty applications like bridges and buildings.

hierro fundido

In manufacturing, cast iron is widely used to produce engine blocks and other components in the automotive industry. Its ability to withstand high temperatures and pressures makes it an excellent choice for machinery and industrial equipment. Additionally, cast iron cookware, such as skillets, Dutch ovens, and griddles, remains popular due to its excellent heat retention and distribution, making it favored by chefs and home cooks alike.

Moreover, cast iron pipes have historically been utilized for water and sewage systems due to their resistance to corrosion and longevity. Although modern plastics have replaced cast iron in some instances, its resilience continues to be valued in specific scenarios.

Benefits of Cast Iron

One of the primary advantages of cast iron is its cost-effectiveness. Compared to other metals, it is relatively inexpensive to produce and requires minimal maintenance. The durability and longevity of cast iron products often offset the initial investment, as they can last for generations with proper care.

Another significant benefit is its recyclability. Cast iron can be melted down and reused without losing its inherent properties, making it an environmentally friendly choice. This recyclability contributes to the sustainability of industries that rely on cast iron, aligning with modern environmental standards.

In summary, cast iron remains a fundamental material in various sectors due to its unique properties, versatility, and cost-effectiveness. From construction and manufacturing to cookware, its applications are diverse and significant. As industries continue to evolve, the use of cast iron will likely adapt and persist, maintaining its relevance in an ever-changing technological landscape. Understanding the value of cast iron ensures that it remains a favored choice for engineers, manufacturers, and consumers alike.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters