High-Quality Decorative Iron Castings & Ornamental Designs

The Enduring Appeal and Technical Excellence of Decorative Iron Castings

In the realm of architectural design, urban landscaping, and heritage restoration, decorative iron castings stand as a testament to durability, aesthetic versatility, and engineering precision. These meticulously crafted components are more than mere functional elements; they are integral to defining the character and grandeur of structures and spaces. From intricate fencing to ornate street furniture and structural embellishments, the demand for high-quality ornamental iron castings continues to grow, driven by a blend of classical design principles and modern material science.

The market for decorative cast iron is experiencing a resurgence, fueled by projects requiring authentic period aesthetics, robust material performance, and sustainable manufacturing practices. Industries such as luxury residential development, commercial facade construction, public infrastructure enhancement, and historical preservation increasingly rely on suppliers capable of delivering both standard and bespoke solutions. This section delves into the evolving industry trends, fundamental technical specifications, diverse application scenarios, and the inherent advantages that position decorative iron castings as a preferred choice for discerning professionals.

Our focus here is to provide B2B decision-makers, architects, engineers, and procurement specialists with a comprehensive understanding of the value proposition offered by modern ornamental iron castings, emphasizing their longevity, design flexibility, and critical role in creating lasting aesthetic impact.

Manufacturing Process: From Raw Material to Refined Ornamental Cast Iron Parts

The creation of high-quality decorative iron castings is a sophisticated process that combines traditional craftsmanship with advanced metallurgical and manufacturing techniques. It begins with careful material selection and progresses through a series of precise steps to ensure the final product meets stringent aesthetic and structural requirements. Here is a detailed overview of the typical manufacturing flow:

Process Flow of Decorative Iron Castings:

- 1. Design and Pattern Making: The journey starts with a detailed design, often computer-aided (CAD), which translates aesthetic visions into engineering blueprints. From these, a physical pattern (typically made from wood, plastic, or metal) is created. This pattern is a replica of the desired casting, slightly oversized to account for material shrinkage during cooling.

- 2. Mold Creation: Sand molding is the most common method for ornamental cast iron parts due to its cost-effectiveness and ability to capture intricate details. The pattern is pressed into a mixture of sand, clay, and water (green sand) or chemically bonded sand, forming a two-part mold (cope and drag). Internal passages or hollow sections are formed using sand cores.

- 3. Material Melting and Alloying: High-grade pig iron, steel scrap, and alloying elements (e.g., silicon, manganese, carbon, sulfur, phosphorus) are melted in an induction furnace or cupola furnace. The precise composition is critical for achieving desired mechanical properties, such as tensile strength, hardness, and corrosion resistance. Gray cast iron (ASTM A48 Class 30-40) is frequently used for decorative applications due to its excellent castability and dampening properties.

- 4. Pouring: Once the molten metal reaches the correct temperature and chemical composition, it is carefully poured into the prepared molds. The pouring temperature and rate are crucial to prevent defects like cold shuts or misruns.

- 5. Cooling and Solidification: The molten iron is allowed to cool and solidify within the mold. The cooling rate influences the microstructure and, consequently, the mechanical properties of the casting. Controlled cooling minimizes internal stresses.

- 6. Shakeout and Cleaning: After solidification, the casting is removed from the sand mold (shakeout). Gates, risers, and excess sand are then meticulously removed.

- 7. Finishing and Machining: Raw castings undergo grinding, deburring, and shot blasting to achieve a smooth surface finish. For components requiring precise dimensions or assembly, CNC machining may be employed to ensure tight tolerances. This is particularly relevant for interfaces or mounting points.

- 8. Quality Control and Testing: Each batch of castings undergoes rigorous quality checks. This includes visual inspection for surface defects, dimensional checks, and material testing (e.g., spectral analysis for chemical composition, hardness tests, tensile strength tests). Non-destructive testing methods like ultrasonic testing or magnetic particle inspection may be applied for critical components. Products are tested against international standards such as ISO 9001 for quality management and ASTM A48 for cast iron specifications.

- 9. Surface Treatment and Coating: For protective and aesthetic purposes, castings receive various surface treatments, including priming, powder coating, galvanizing, or painting. These coatings enhance corrosion resistance and provide the desired finish, ensuring a service life of decades even in challenging environments.

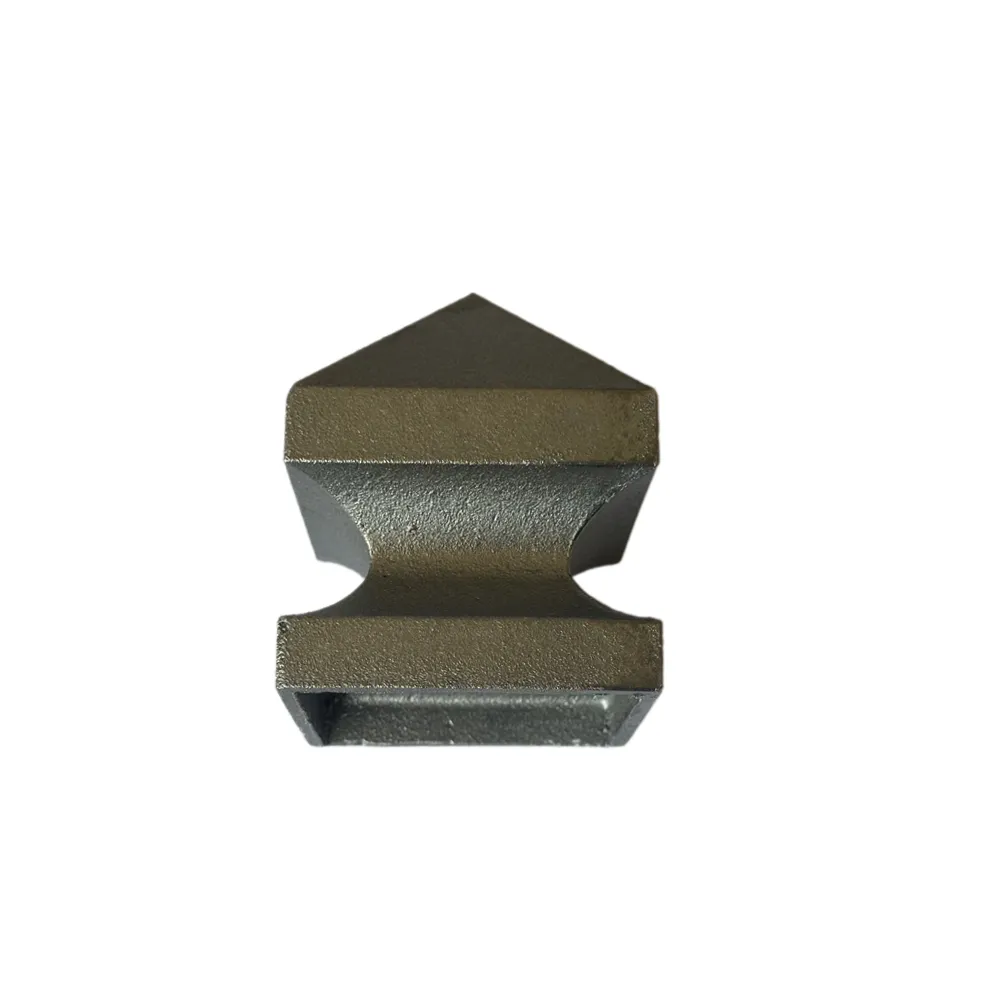

Fig 1: Precision molding for intricate decorative cast iron components.

While specific processes like forging are more suitable for wrought iron with different mechanical properties, casting excels at producing complex shapes and intricate details characteristic of decorative iron castings. The inherent material properties of cast iron, coupled with advanced surface treatments, ensure excellent corrosion resistance and an exceptionally long service life, often exceeding 50 years with proper maintenance. This makes them ideal for architectural, urban development, and landscaping applications.

Technical Specifications and Parameters

Understanding the technical specifications of ornamental iron casting is crucial for architects and engineers to ensure material compatibility, structural integrity, and long-term performance. While specific properties can vary based on the alloy and casting process, certain parameters are consistently evaluated.

Typical Material Specifications for Decorative Cast Iron Components (e.g., Fence Post Caps):

| Parameter | Description/Value | Relevant Standard |

|---|---|---|

| Material Grade | Gray Cast Iron (e.g., GG20, GG25, GG30) | EN 1561, ASTM A48 Class 30/35 |

| Tensile Strength | 200 - 250 MPa (GG20/GG25) | EN 1561 |

| Compressive Strength | ~700 - 1000 MPa (significantly higher than tensile) | |

| Hardness (Brinell) | 160 - 220 HB | EN ISO 6506-1 |

| Corrosion Resistance | Excellent, especially with surface treatment (e.g., galvanizing, powder coating, zinc phosphate priming) | ISO 9227 (Salt Spray Test) |

| Fatigue Strength | Good, particularly for static or low-cycle loading | |

| Density | Approx. 7.1 - 7.3 g/cm³ | |

| Dimensional Tolerances | ISO 8062-3 CT10-CT12 (depending on complexity and size) | ISO 8062-3 |

These parameters underscore the robust nature of cast iron, making it highly suitable for outdoor applications where durability and resistance to environmental factors are paramount. The specific material grade is selected based on the component's structural role and the level of detail required for the cast iron ornamental fence or other decorative elements.

Fig 2: A variety of highly detailed ornamental cast iron parts ready for finishing.

Quality Assurance and Certifications:

Reputable manufacturers adhere to international quality management systems, such as ISO 9001:2015, ensuring consistency in production and product quality. Material certifications (e.g., ASTM, EN) and traceability are standard practices, providing assurance of the material's integrity and performance. Regular internal and third-party audits verify compliance with these stringent standards, giving clients confidence in the reliability and longevity of their decorative cast iron investments.

Application Scenarios and Technical Advantages

The versatility of decorative iron castings allows for their integration into a wide array of architectural and urban landscape projects, offering both aesthetic appeal and robust functionality. Their inherent properties provide distinct technical advantages over other materials.

Key Application Scenarios:

- Architectural Facades & Features: Used for ornate balustrades, grilles, window boxes, decorative columns, and cornices on historical buildings, commercial properties, and luxury homes.

- Fencing and Gate Systems: Intricate fence panels, posts, finials, and especially decorative cast iron post collar elements are fundamental to creating secure, elegant perimeters for estates, public parks, and commercial complexes. The product mentioned, "Cast Iron Fence Post Caps/Gate Tops," falls directly into this category, providing both protection and enhancement to fence posts.

- Urban Furniture & Streetscapes: Benches, lamp posts, bollards, tree grates, and signage brackets benefit from the heavy-duty nature and classic aesthetic of ornamental iron castings, contributing to durable and attractive public spaces.

- Heritage Restoration: Essential for replicating historically accurate components, ensuring that renovations maintain the original architectural integrity of period properties and monuments.

- Landscape Design: Used in garden features, fountains, planters, and decorative grates to add character and permanence to outdoor environments.

Technical Advantages:

- Exceptional Durability and Longevity: Cast iron is renowned for its robustness and resistance to wear and tear. When properly coated, decorative iron castings can withstand harsh weather conditions, UV exposure, and environmental pollutants for decades, far exceeding the lifespan of many alternative materials. This leads to significantly lower life-cycle costs.

- Superior Corrosion Resistance (with Treatment): While cast iron can rust if unprotected, modern surface treatments such as galvanization, e-coating, and high-performance powder coatings provide an impenetrable barrier, making them highly resistant to corrosion, rust, and chipping. This ensures their aesthetic integrity and structural soundness remain intact over time.

- High Compressive Strength: Cast iron exhibits excellent compressive strength, making it ideal for structural elements that bear heavy loads, such as posts and supports in a cast iron ornamental fence.

- Design Versatility and Intricacy: The casting process allows for the creation of incredibly complex and fine details, patterns, and textures that are difficult or impossible to achieve with other fabrication methods. This enables designers to realize elaborate aesthetic visions, from classical motifs to contemporary designs.

- Stability and Weight: The inherent weight of cast iron provides superior stability for freestanding structures like bollards and lampposts, resisting vandalism and accidental impacts.

- Low Maintenance: Once installed and finished, decorative cast iron elements require minimal maintenance, typically limited to occasional cleaning or recoating after many years, contributing to reduced operational expenses.

- Sustainability: Cast iron is 100% recyclable, making it an environmentally responsible choice. Its extreme longevity also reduces the frequency of replacement, further minimizing environmental impact.

Fig 3: Intricate ornamental iron castings enhancing a public park setting.

These advantages position decorative iron castings as a premium material choice for projects where long-term performance, aesthetic appeal, and minimal lifecycle costs are paramount considerations.

Vendor Comparison and Customized Solutions

Selecting the right vendor for decorative iron castings is a critical decision that impacts project timelines, budget, and the ultimate quality and longevity of the installed components. Key factors to consider include manufacturing capabilities, quality control, customization options, and after-sales support.

Vendor Comparison Considerations:

| Feature | Reputable Manufacturer (e.g., Supplier A) | Standard Supplier (e.g., Supplier B) |

|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM/EN Material Compliance | Basic or No Certifications |

| Customization Capability | Full design and pattern making, bespoke solutions | Limited to minor modifications of existing patterns |

| Material Traceability | Comprehensive, from raw material to finished product | Partial or none |

| Surface Treatment Options | Hot-dip galvanizing, powder coating, e-coating, various paints | Basic priming or painting |

| Lead Time Consistency | Reliable, transparent, with project management | Variable, potential delays |

| Warranty & Support | Comprehensive product warranty, dedicated customer service | Limited or no explicit warranty |

Choosing a vendor with proven expertise in ornamental iron castings ensures not only product quality but also provides peace of mind through reliable partnership and support.

Customized Solutions for Unique Projects:

One of the most significant advantages of partnering with a specialized manufacturer of decorative iron castings is the ability to commission customized solutions. This is particularly valuable for architects and designers seeking to realize specific aesthetic visions or replicate historical elements. Customization capabilities typically include:

- Bespoke Design & Prototyping: From concept sketches to detailed CAD models and physical prototypes, leading manufacturers can transform unique designs into functional patterns and molds. This allows for tailored dimensions, motifs, and architectural styles.

- Material & Finish Options: Beyond standard gray cast iron, specific alloys can be utilized for enhanced properties. A wide range of finishing options, including custom colors for powder coating or specialized patinas, allows for precise aesthetic matching.

- Reverse Engineering: For heritage restoration projects, components can be reverse-engineered from existing samples or historical drawings to produce historically accurate reproductions of decorative cast iron elements.

- Integrated Solutions: Manufacturers often offer integrated solutions, such as pre-drilling for installation, factory assembly of multiple components (e.g., a decorative cast iron post collar with a specific post), or custom packaging for large-scale projects.

Fig 4: Examples of customizable decorative iron castings for various applications.

This level of customization is invaluable for distinguishing projects and ensuring that every architectural detail contributes to a cohesive and distinguished final product.

Application Case Studies

Real-world applications demonstrate the practical advantages and aesthetic impact of decorative iron castings in diverse projects.

Case Study 1: Heritage Building Façade Restoration

Project Brief: Restoration of a late 19th-century municipal building's facade, requiring the replacement of severely corroded original cast iron balustrades and decorative window grilles. The challenge was to replicate the intricate historical patterns precisely while ensuring modern material longevity.

- Solution: A specialist manufacturer of ornamental iron castings was engaged. They utilized 3D scanning and reverse engineering to create digital models from surviving original fragments. New patterns were then produced to cast replacements using ASTM A48 Class 35 gray cast iron.

- Key Outcomes: The new decorative iron castings perfectly matched the historical aesthetic. Each component was finished with a multi-layer protective coating system (zinc phosphate primer + epoxy + UV-resistant topcoat) to ensure a projected service life of over 75 years, significantly reducing future maintenance cycles and costs. The project garnered praise for its historical accuracy and material integrity.

Case Study 2: High-End Residential Perimeter Fencing

Project Brief: Development of a luxury residential estate requiring a distinctive and highly secure perimeter fence system. The client sought a balance of classic elegance and contemporary durability for their cast iron ornamental fence.

- Solution: Custom-designed cast iron fence panels and posts, incorporating unique finials and robust decorative cast iron post collar elements, were commissioned. The components were cast from GG25 grade iron, hot-dip galvanized for superior corrosion protection, and then powder-coated in a bespoke color.

- Key Outcomes: The resulting fence system provided exceptional security and a striking visual impact, enhancing the estate's value and curb appeal. The combination of hot-dip galvanizing and powder coating offered unparalleled resistance to weathering, salt spray, and minor abrasions, guaranteeing a pristine appearance for decades with minimal upkeep.

Case Study 3: Urban Public Park Redevelopment

Project Brief: Modernization of a central city park to include new seating, lighting, and tree protection. The urban planning department prioritized durable, low-maintenance materials that would blend with the natural environment while resisting vandalism.

- Solution: Heavy-duty decorative iron castings were selected for benches, custom-designed tree grates, and bollards. The tree grates, in particular, featured an intricate pattern that allowed for optimal water and air penetration while protecting young trees. All components were finished with an anti-graffiti powder coating.

- Key Outcomes: The cast iron elements proved highly resistant to impact and weathering, providing robust, long-lasting infrastructure. The aesthetic contribution of the ornamental iron casting components elevated the park's appeal, creating a welcoming and durable urban space that met public safety and aesthetic requirements.

Frequently Asked Questions (FAQ)

- Q1: What are the primary advantages of decorative iron castings over fabricated steel or aluminum?

- A1: Cast iron excels in intricate design capabilities, offering a classic aesthetic that is difficult to replicate with fabrication. It has superior compressive strength and inherent mass for stability. With proper surface treatment, cast iron also provides excellent corrosion resistance and an exceptionally long service life, often exceeding that of fabricated steel or aluminum in outdoor, high-traffic environments, leading to lower total cost of ownership.

- Q2: How durable are ornamental cast iron parts in harsh weather conditions?

- A2: When treated with high-quality protective coatings such as hot-dip galvanization, e-coating, or industrial-grade powder coating, decorative iron castings are extremely durable. They resist rust, UV degradation, and temperature fluctuations, making them ideal for coastal, urban, or extreme weather environments. A well-maintained cast iron product can last for over 50 years.

- Q3: Can decorative cast iron components be customized?

- A3: Absolutely. Customization is a key strength of the casting process. Manufacturers can produce unique patterns, dimensions, and motifs based on client specifications, architectural drawings, or historical references. This includes bespoke designs for a decorative cast iron post collar, fence finials, or entire fence panels.

- Q4: What is the typical lead time for an order of ornamental iron casting?

- A4: Lead times vary significantly based on the complexity of the design, order volume, and whether custom patterns are required. For standard products, it can range from 4-8 weeks. For highly customized or large-scale projects, it may extend to 10-16 weeks to account for pattern creation, sampling, and production. It's always best to consult directly with the manufacturer for precise timelines based on your project requirements.

- Q5: What kind of warranty and after-sales support can I expect?

- A5: Reputable manufacturers typically offer a comprehensive warranty, often spanning 5-10 years, covering material defects and coating integrity under normal conditions. After-sales support includes technical assistance for installation, maintenance guidelines, and assistance with any potential issues. Detailed terms and conditions are usually provided with a quotation or contract.

Logistics, Warranty, and Customer Support

Understanding the practical aspects of procurement and long-term support is essential for any B2B engagement involving decorative iron castings.

Lead Time and Fulfillment:

Our streamlined production processes and efficient supply chain management ensure timely delivery. For standard components, typical lead times range from 4 to 8 weeks, including manufacturing and quality checks. Custom orders, which involve pattern creation and detailed prototyping, generally require 10 to 16 weeks, depending on complexity and order volume. We provide transparent project timelines and dedicated project managers to keep clients informed at every stage, from initial design review to final shipment. We offer various shipping options, including sea freight and air cargo, to meet specific project deadlines and budget constraints globally.

Warranty Commitments:

We stand by the quality and durability of our ornamental cast iron parts. All products are backed by a comprehensive 5-year limited warranty against manufacturing defects and premature coating failure under normal use and maintenance. This commitment reflects our confidence in our materials and processes, giving our clients assurance in their investment.

Dedicated Customer Support:

Our commitment extends beyond delivery. We provide dedicated customer support to assist with technical queries, installation guidance, and any post-purchase requirements. Our team of experts is available to offer professional advice, ensuring that our decorative iron castings perform optimally throughout their impressive service life. We pride ourselves on building long-term relationships through reliable service and responsive communication.

Conclusion

Decorative iron castings represent a convergence of historical artistry and modern engineering, offering unparalleled durability, aesthetic flexibility, and long-term value for a diverse range of architectural and urban development projects. From the meticulous manufacturing process to the rigorous quality controls and the extensive customization options, these components provide a robust and elegant solution that stands the test of time. For B2B decision-makers, investing in high-quality ornamental iron casting means choosing a material solution that delivers exceptional performance, minimal maintenance, and enduring beauty, ensuring the success and longevity of their ventures.

References

- ASTM International. (2020). ASTM A48/A48M-03(2020) Standard Specification for Gray Iron Castings.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- European Committee for Standardization. (2019). EN 1561:2019 Founding - Grey cast irons.

- ASM International. (2015). ASM Handbook Volume 15: Casting.

- National Institute of Standards and Technology. (2021). Corrosion Protection of Cast Iron Structures.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges