how much is wrought iron worth

The Value of Wrought Iron Understanding Its Worth

Wrought iron, known for its malleability and resistance to corrosion, has been a crucial material in various applications for centuries. Its unique properties and aesthetic appeal make it a sought-after choice in architecture, furniture design, and decorative arts. But how much is wrought iron worth today? Understanding its value involves considering several factors, including market demand, production costs, and comparator materials.

Historical Context

Wrought iron, comprised mainly of iron with a small percentage of slag, has been used since ancient times. The strength and ductility of wrought iron made it preferable over cast iron in many applications. In the past, the costs associated with wrought iron production were much higher due to labor-intensive smelting and forging techniques. However, advancements in technology and production methods have significantly impacted its market value.

Current Market Value

As of today, the price of wrought iron fluctuates based on several factors, including the global supply of raw materials, production costs, and market demand. The metal market can be volatile, with prices changing frequently due to economic conditions, trade policies, and the availability of alternative materials, such as stainless steel or aluminum.

Generally, wrought iron can range between $1.50 to $3.00 per pound, though prices may vary by region and manufacturer. Specialized wrought iron products, like ornamental gates or intricate railings, may cost considerably more due to the craftsmanship involved. In contrast, bulk purchases or lower-grade iron may be cheaper but lack the unique properties that make wrought iron desirable.

Production Costs

how much is wrought iron worth

The cost of producing wrought iron is another critical factor influencing its market value. Wrought iron is typically produced through a process known as puddling, where pig iron is melted and refined with a limited amount of carbon. This labor-intensive process results in a more malleable material, capable of being shaped at lower temperatures than cast iron. The skill required in forging wrought iron also contributes to its higher price.

Moreover, the recent global supply chain disruptions and rising energy costs have affected manufacturing expenses, further influencing the retail price of wrought iron.

Demand for Wrought Iron

The demand for wrought iron remains consistent, particularly in industries focused on historical restoration, custom decorative arts, and high-end construction projects. Homeowners and architects often prefer wrought iron for railings, gates, and fences because it combines durability with timeless aesthetic appeal.

On the other hand, the trend towards more affordable and lightweight materials has led some sectors to move away from wrought iron products. While this may affect its market share, the distinctive qualities of wrought iron ensure its continued popularity amongst artisans and those looking for high-quality, lasting products.

Conclusion

In conclusion, the worth of wrought iron is influenced by various factors, including historical significance, production costs, and market demand. While it may not be the cheapest material available, the unique properties and aesthetic charm of wrought iron make it an enduring choice for many applications. Understanding these factors provides insight into why wrought iron continues to be valued in today’s market, even in a landscape filled with alternatives.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

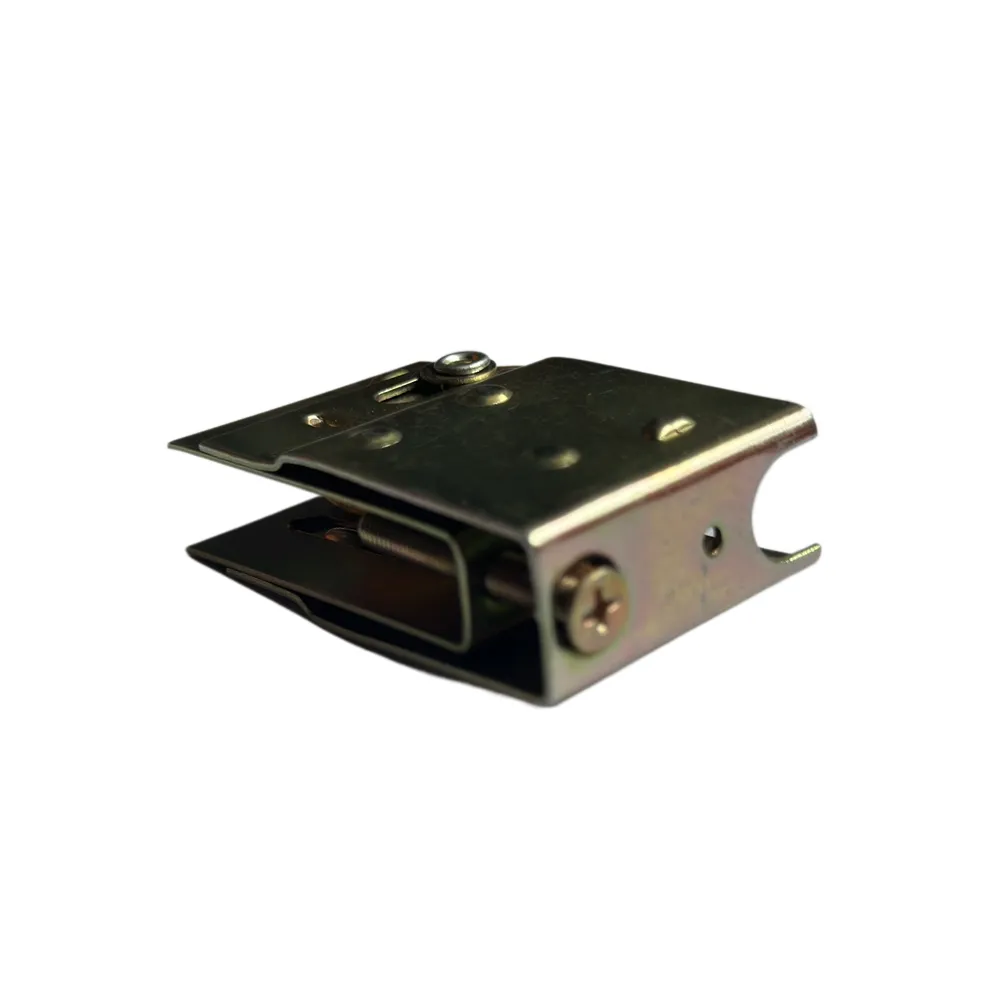

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters