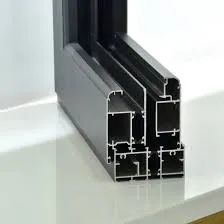

industrial sliding door rollers

Industrial Sliding Door Rollers Enhancing Efficiency and Functionality

Industrial sliding doors are crucial in various sectors, providing both accessibility and security. One of the most vital components of these doors is the sliding door rollers. These small but significant devices are integral to the smooth operation of sliding doors in industrial settings, such as warehouses, factories, and distribution centers.

Functionality and Design

Sliding door rollers are designed to facilitate the seamless movement of heavy doors along their tracks. They support the door's weight, allowing it to glide effortlessly without excessive force. The functionality of these rollers directly impacts the efficiency of operations. When doors operate smoothly, they minimize downtime, ensuring that workflows are uninterrupted. This is particularly important in environments where time is critical, and delays can lead to significant costs.

The design of industrial sliding door rollers is tailored to withstand heavy loads and harsh conditions. Typically made from durable materials such as stainless steel or high-strength plastics, these rollers can resist corrosion, wear, and tear. Many industrial settings are subject to extreme temperatures, moisture, and dust, making it essential for rollers to maintain their performance without frequent maintenance.

Types of Sliding Door Rollers

industrial sliding door rollers

There are several types of sliding door rollers available, each suitable for different applications. For instance, there are center-hung rollers, commonly used in large doors that require vertical support. There are also top-mounted rollers that enhance the aesthetic appeal by keeping the track concealed from view. For heavy-duty applications, heavy-duty rollers are engineered to hold significant weight, ensuring safety and reliability.

The choice of roller largely depends on the specific requirements of the industrial environment. Factors such as door weight, material, and frequency of use all play a role in determining the most appropriate roller. It is crucial to select the right type of sliding door rollers to enhance operational efficiency and ensure safety.

Maintenance and Inspection

Regular maintenance and inspection of sliding door rollers are essential to ensure optimal performance and longevity. Industrial environments can be demanding, and neglecting roller maintenance can lead to malfunctions that disrupt operations. Routine checks should include inspecting for wear, ensuring the tracks are clear of debris, and lubricating the rollers to minimize friction. Addressing minor issues promptly can prevent larger, costlier repairs in the future.

Conclusion

In conclusion, industrial sliding door rollers play a vital role in the efficient operation of sliding doors. Their design, functionality, and maintenance directly affect how well doors perform in demanding industrial environments. Choosing the right type of roller and ensuring regular maintenance can significantly enhance productivity and safety. As industries continue to evolve, investing in quality sliding door rollers will remain a priority for businesses aiming to optimize their operations and improve workflow efficiency.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters