iron material suppliers

The Importance of Iron Material Suppliers in Manufacturing Industries

In the contemporary manufacturing landscape, iron remains a cornerstone material due to its unparalleled strength, durability, and versatility. As industries strive for innovation and efficiency, the role of iron material suppliers becomes increasingly critical. These suppliers play a vital role not only in providing the raw materials but also in ensuring that businesses can achieve their production goals in a timely and cost-effective manner.

The Role of Iron in Various Industries

Iron is pivotal to various sectors, including construction, automotive, machinery, and many more. Its ability to withstand heavy loads makes it an ideal choice for construction projects, such as skyscrapers and bridges. The automotive industry leverages iron for chassis and engine components, which require materials that can endure extreme conditions while maintaining structural integrity. Furthermore, in manufacturing, iron serves as a primary component in machines and tools, underscoring its essential role.

The Significance of Reliable Suppliers

The reliability of iron suppliers directly impacts production efficiency. A dependable supplier ensures timely delivery of iron materials, which is crucial for maintaining the flow of production. Delays in material supply can halt manufacturing processes, leading to costly downtime and missed deadlines. Therefore, businesses often prioritize establishing partnerships with suppliers who have a proven track record of reliability and quality.

Moreover, quality control in iron production is paramount. Different grades of iron are required for specific applications, and suppliers must adhere to strict industry standards. This responsibility includes providing certifications that verify the quality and composition of the materials. High-quality iron not only enhances the final product’s performance but also minimizes the likelihood of defects and failures, which can have severe implications in terms of safety and costs.

Sustainable Practices in Iron Supply

iron material suppliers

As global focus shifts towards sustainability, iron material suppliers are also adapting to meet environmental standards and regulations. The steel industry, which heavily relies on iron, has made substantial advancements in recycling and reducing carbon emissions. Suppliers who adopt eco-friendly practices and provide recycled iron contribute to a more sustainable supply chain, a factor increasingly valued by consumers and manufacturers alike.

Sustainable suppliers can not only reduce environmental impact but also enhance their market competitiveness. Businesses that prioritize sustainability often experience a positive brand image and greater customer loyalty, making it imperative for suppliers to align with these values.

Technological Advancements and Innovations

The landscape of iron supply is continually evolving with technological advancements. Automation and digitalization have streamlined supply chain processes, enabling suppliers to track inventory accurately, predict demand, and adjust production schedules efficiently. Innovations in logistics and transportation further ensure that materials reach manufacturers promptly and in optimal condition.

Additionally, advances in metallurgical research have introduced new alloys and materials that expand the application of iron in various industries. Suppliers that embrace these innovations can offer more diverse options, catering to the specific needs of their clients, thus fostering stronger partnerships.

Conclusion

Iron material suppliers play a critical role in the manufacturing ecosystem, influencing everything from production efficiency to product quality. As industries continue to evolve, the importance of reliable, sustainable, and innovative suppliers cannot be overstated. By prioritizing quality and sustainability, iron suppliers can meet the changing demands of the market, fostering resilience and growth in the manufacturing sector. As we look to the future, the collaboration between manufacturers and iron material suppliers will be vital in driving advancement and ensuring a robust industrial landscape.

-

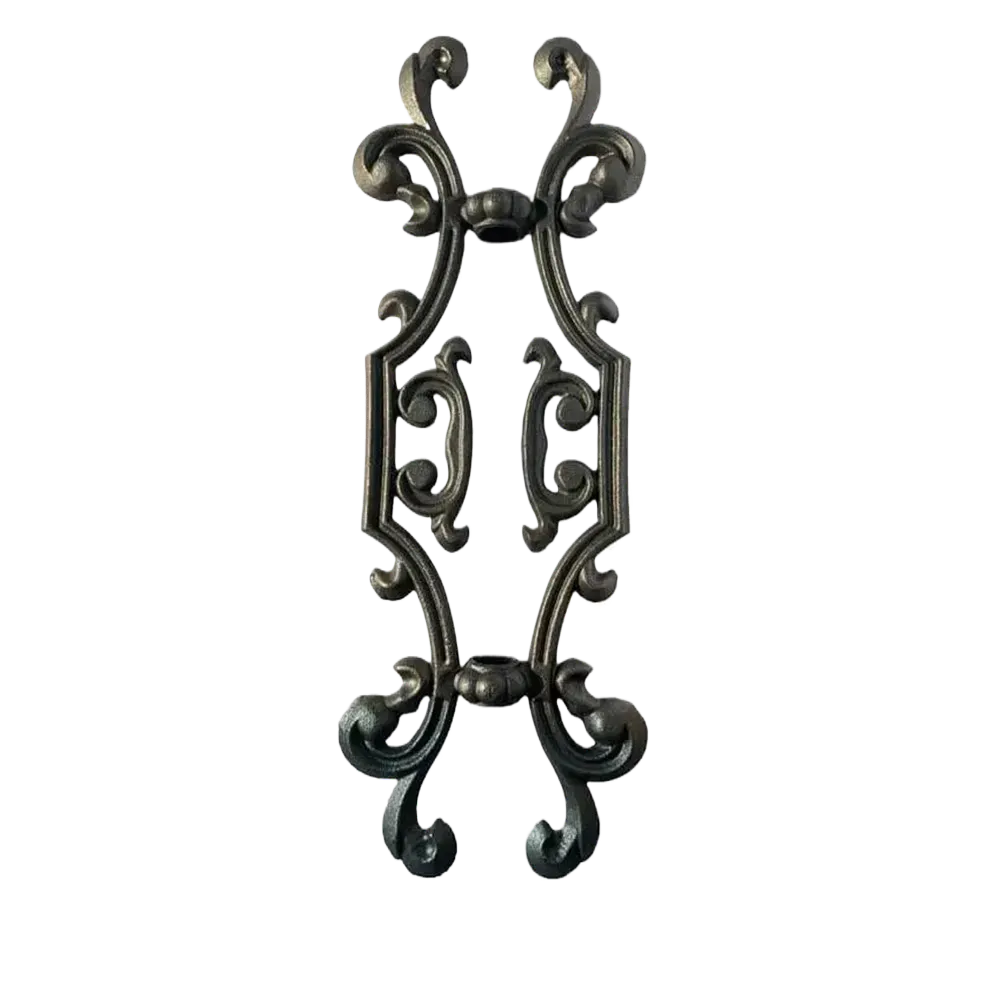

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters