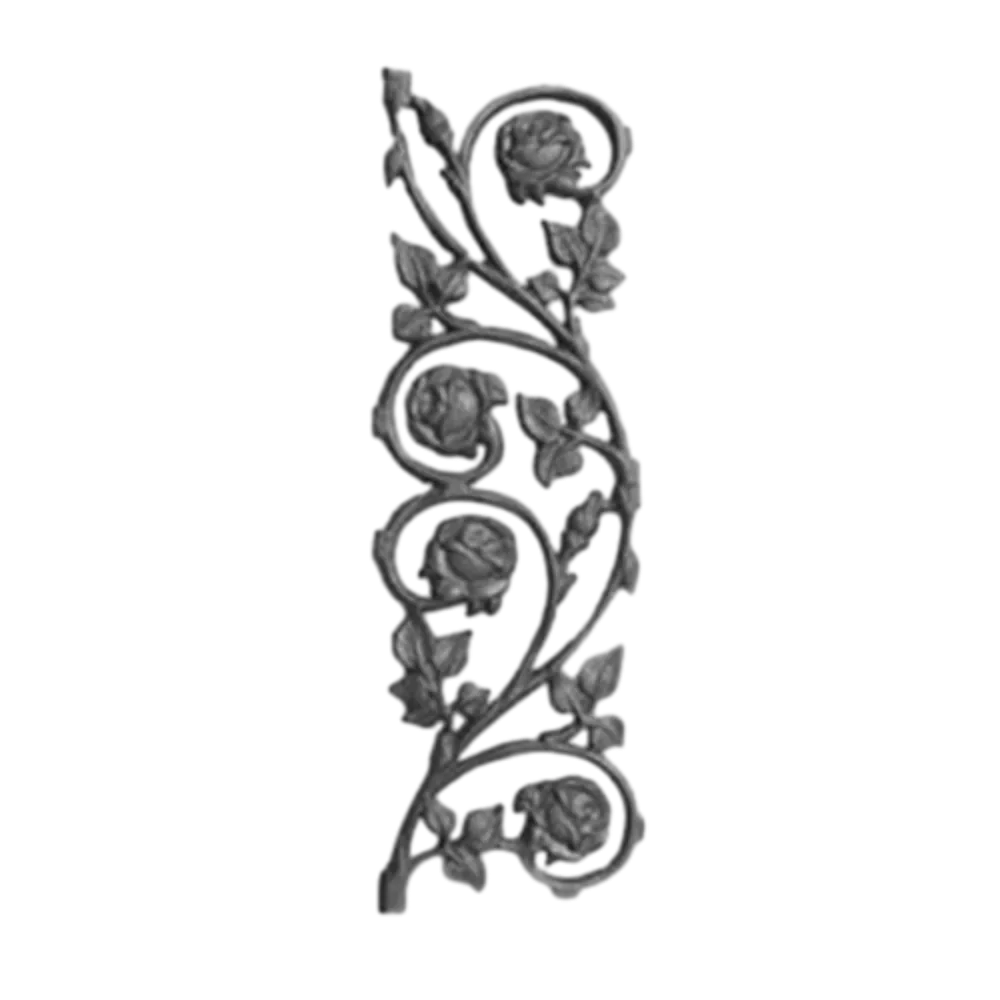

Cast Iron Macolla Design and Its Artistic Applications in Contemporary Crafts

The Significance of Cast Iron Machining in Modern Manufacturing

Cast iron has played a critical role in various manufacturing processes for centuries, owing to its remarkable properties such as durability, corrosion resistance, and the ability to retain shape. Machining cast iron, or macolla de hierro fundido, as it is referred to in Spanish, involves the processes of shaping and finishing cast iron components to meet specific dimensions and tolerances. This article will delve into the importance of cast iron machining, its applications, challenges, and advancements in modern manufacturing techniques.

Properties of Cast Iron

Cast iron is an alloy of iron, carbon, and silicon, typically containing between 2% to 4% carbon. This distinctive composition results in a material that is both robust and malleable, making it an ideal choice for numerous applications. Cast iron exhibits excellent wear resistance, excellent casting characteristics, and superior thermal conductivity, which are vital properties in industries ranging from automotive to aerospace.

One of the standout features of cast iron is its ability to absorb vibrations, which is why it is frequently used in the production of engine blocks, machine bases, and other components that require stability and noise reduction. The malleability of cast iron allows it to be cast into complex shapes, which is essential in creating intricate parts for machinery.

Applications in Various Industries

The versatility of cast iron has led to its widespread usage in various sectors. In the automotive industry, components such as cylinder heads, crankshafts, and brake discs are often made from cast iron due to its ability to withstand high temperatures and pressures. In the construction sector, cast iron is commonly utilized for pipes, manhole covers, and building facades, benefiting from its durability and low maintenance requirements.

Furthermore, in the manufacturing of kitchenware, materials such as cast iron skillets and Dutch ovens have gained popularity for their even heat distribution and superior cooking performance. The culinary industry has reaffirmed the value of cast iron in homes and restaurants alike.

Challenges in Machining Cast Iron

macolla de hierro fundido

Despite its many advantages, machining cast iron presents several challenges. One of the primary concerns is tool wear. The hard and abrasive nature of cast iron can lead to rapid degradation of cutting tools. To overcome this, manufacturers often employ cutting tools made from high-speed steel or carbide, designed to endure the abrasive properties of cast iron.

Another challenge is controlling the machining process, as the material can produce large amounts of chips and dust, which poses hazards for worker safety and equipment maintenance. Additionally, achieving the correct tolerances and surface finish can be complex due to the material's inherent characteristics. Thus, manufacturers must utilize advanced machining techniques and maintain proper equipment to ensure quality outcomes.

Advancements in Machining Techniques

The field of cast iron machining has grown significantly, incorporating modern technology and techniques that enhance productivity and precision. CNC (Computer Numerical Control) machining has revolutionized the industry, allowing for the automatic control of machining processes, which increases efficiency and minimizes human error.

Additive manufacturing techniques, such as 3D printing, are being explored to complement traditional cast iron casting methods. These innovations can lead to faster production times and the ability to create geometrically complex parts that are difficult to achieve through conventional methods.

Furthermore, advancements in cutting fluid technology have allowed manufacturers to achieve better cooling and lubrication during machining, thereby extending tool life and improving surface quality. The integration of smart technology and AI in machining processes promises to further optimize resource management, reduce waste, and enhance overall production capabilities.

Conclusion

In conclusion, macolla de hierro fundido is more than just a term describing cast iron; it encompasses a vital component of modern manufacturing. The significance of cast iron machining lies in its ability to produce high-quality, durable products across a range of industries. Despite the challenges faced in the machining process, advancements in technology and techniques make it a dynamic and evolving field. As industries continue to evolve, the role of cast iron and its machining processes will undoubtedly remain critical in achieving manufacturing excellence.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters